Structure capable of falling down

A technology of rotating structure and locking structure, applied in photovoltaic power generation, sustainable buildings, climate sustainability, etc., can solve the problems of inconvenient operation, insufficient positioning accuracy, poor stability, etc., and achieve reliable overall structure and reliable operation process. , The effect of reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

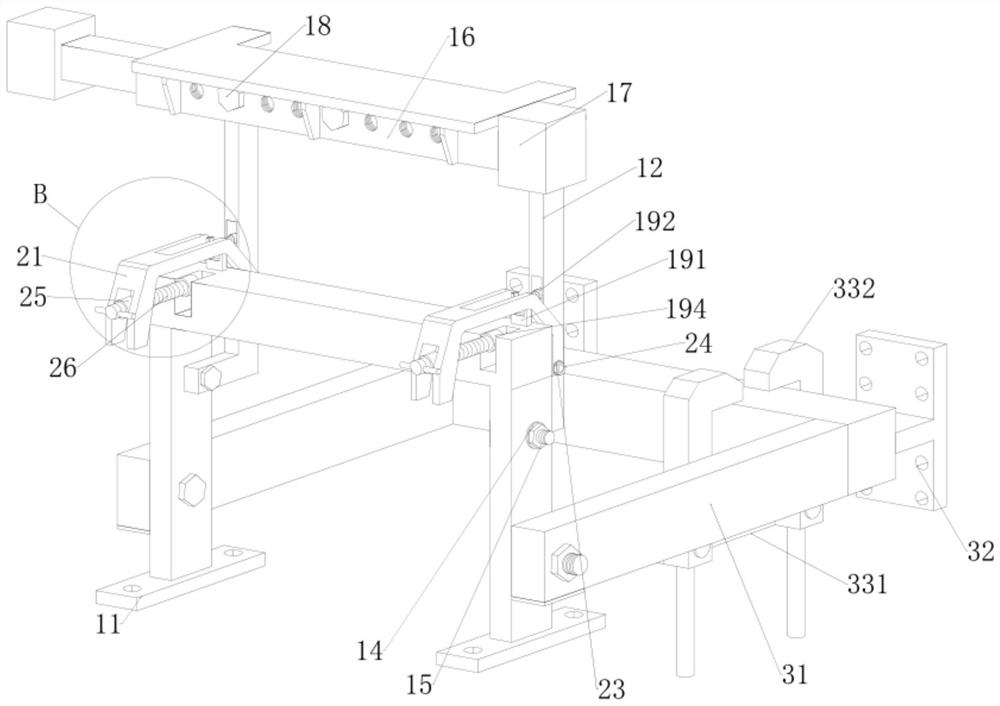

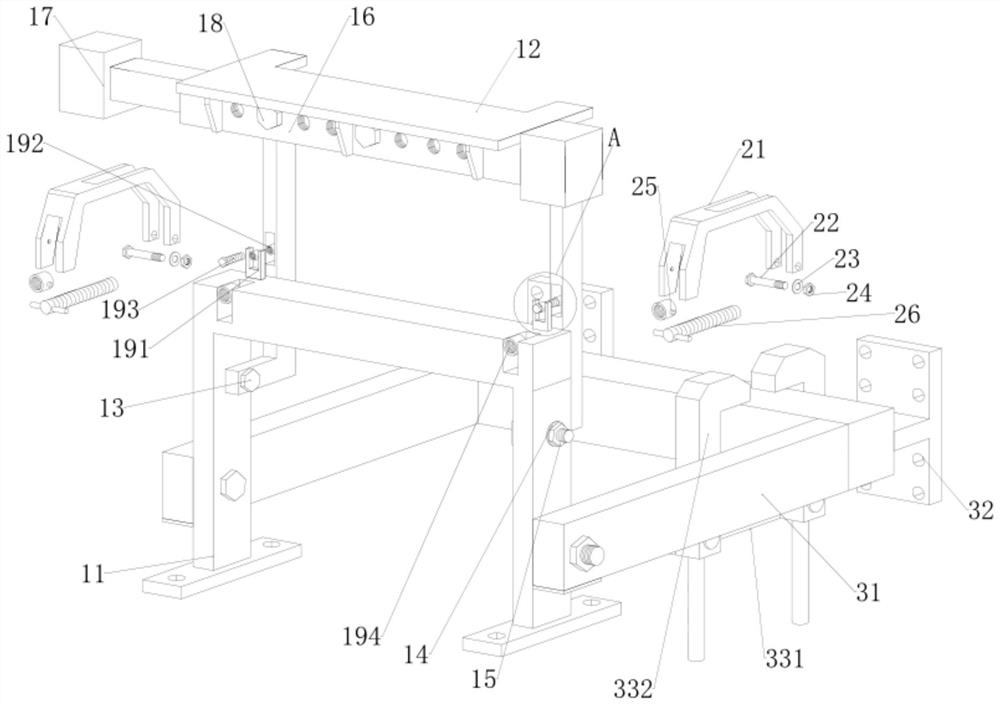

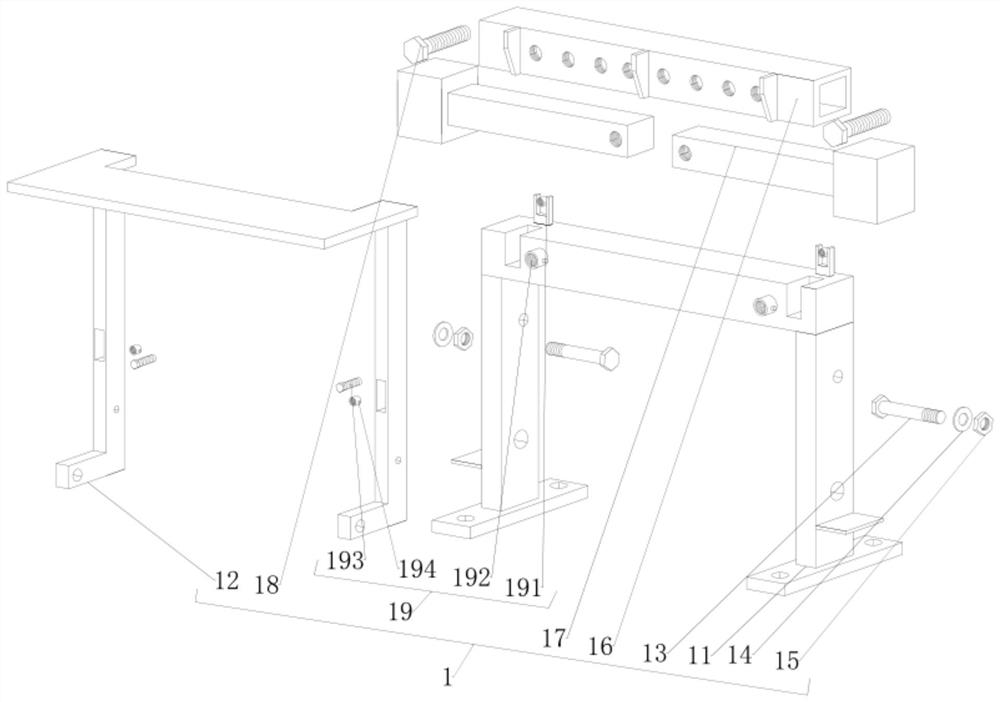

[0046] Example: according to the instructions attached Figure 1-7 It can be seen that, firstly, the fixed bracket 11 in the fixed rotating structure 1 can be installed opposite to the main frame for connecting the conveying carrier, and the conveying carrier mainly includes a skid, a spreader, and a tray; A nut 15 and the first bolt 13 fixed by the first washer 14 are rotated to the working state, and the other end is positioned above the fixing bracket 11 while maintaining the vertical position. The first inversion threaded tube 192 in the limiting seat 191 is then screwed into the first inversion threaded tube 192 in the second inversion groove, so that the rotation is directly constrained by the limiting component 19 (the position can be passed through the first inversion threaded tube 192 The overturning and the rotation of the limit bolt 193 are adjusted to a certain extent) to rotate in place

[0047] Next, after passing through the locking frame 21 in the locking stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com