Integral operation platform for high-rise fabricated building

A working platform and assembled technology, which is applied in the direction of construction, building structure, housing structure support, etc., can solve the problems of affecting the construction progress, increasing construction cost, cumbersome operation, etc., so as to improve construction efficiency, reduce construction cost, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

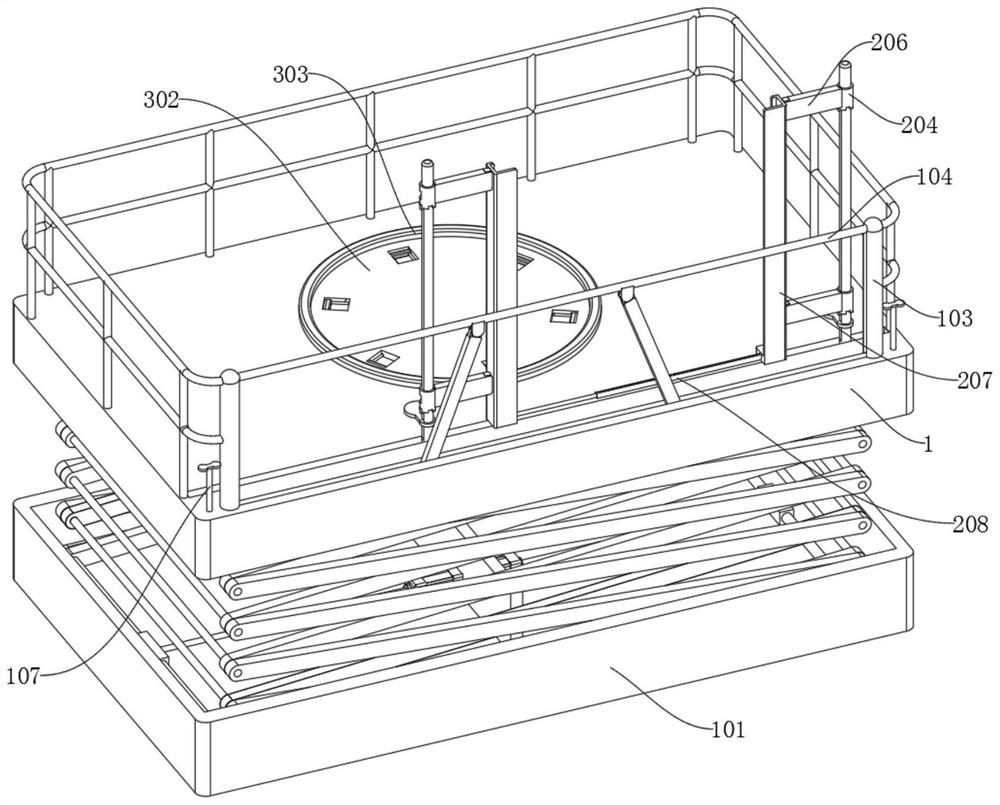

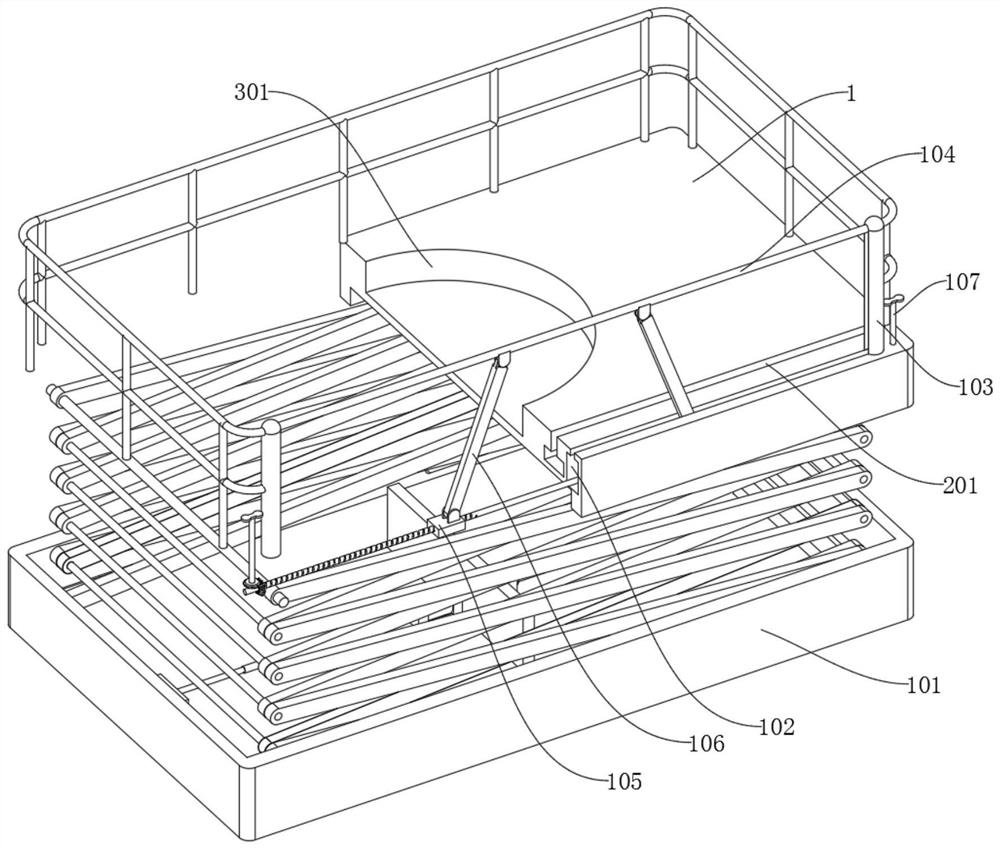

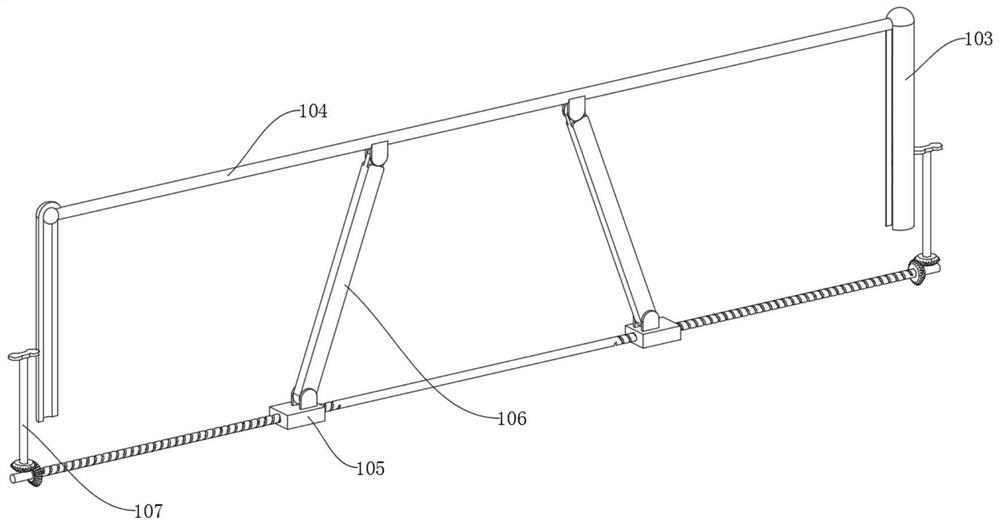

[0037] Example: please refer to Figure 1 to Figure 8 :

[0038] The present invention proposes an integral working platform of a high-rise prefabricated building, comprising: a main body 1, the main body 1 is a rectangular structure, a scissor mechanism is installed at the bottom of the main body 1, a guardrail is installed at the top edge of the main body 1, and the main body 1 A fixed assembly 2 is installed at the top front side of the main body; the fixed assembly 2 includes a sliding rod 203, and the side of the sliding rod 203 is provided with a slot; the steering assembly 3, the steering assembly 3 is installed on the top of the main body 1, and the steering The assembly 3 includes a rotating plate 302, and the top of the rotating plate 302 is provided with six grooves.

[0039]In addition, the main body 1 includes: a base 101, a cylinder is installed on the inner bottom of the base 101, and the base 101 is installed at the bottom of the scissor mechanism at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com