Reusable plastic-wood formwork for concrete pouring

A technology of concrete and plastic wood, which is applied in the processing of formwork, formwork/formwork components, formwork/formwork/work frame, etc., which can solve the problems of affecting building quality, poor formwork fixing effect, and increasing building use costs. , to achieve the effect of improving safety and reliability, improving building construction quality, and improving installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

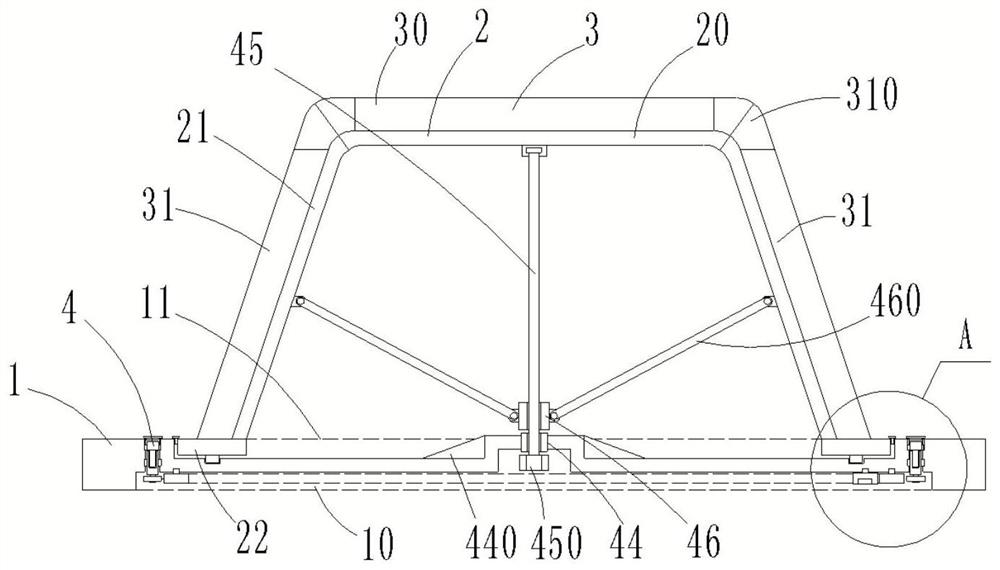

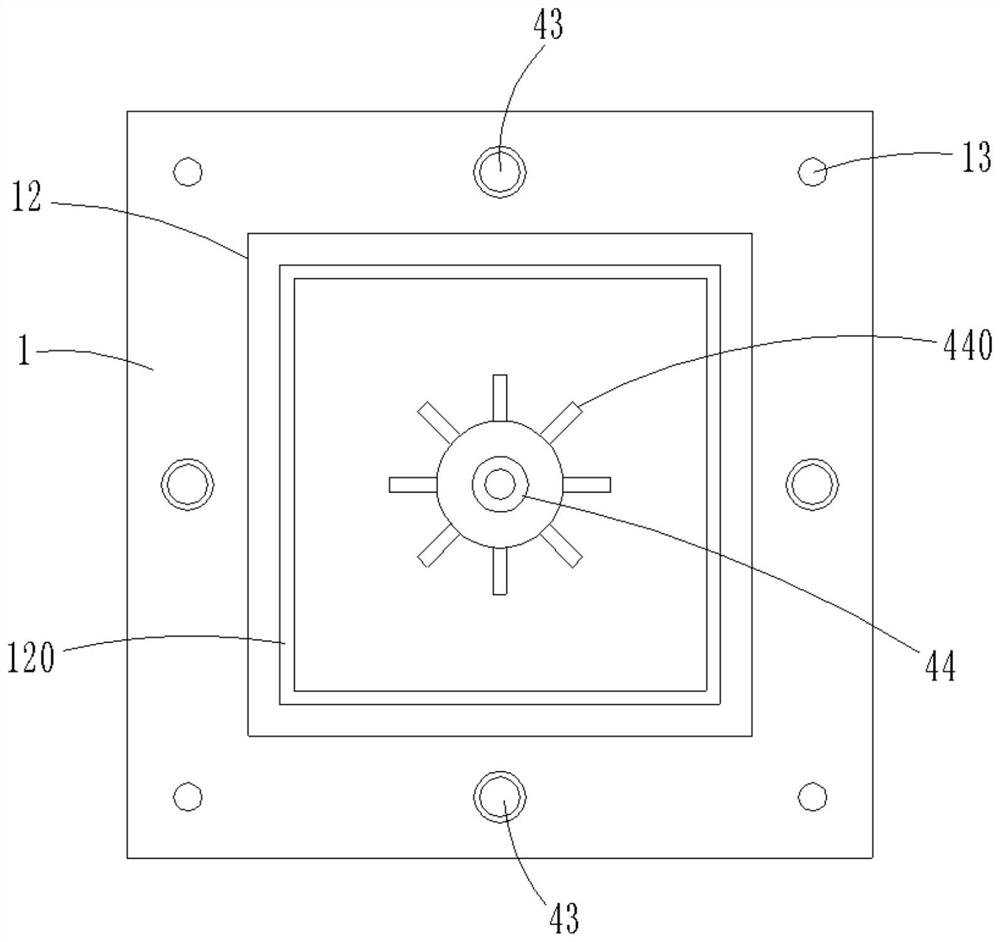

[0037] like figure 1 , 2 A reusable plastic-wood formwork for concrete pouring shown in 4 and 4 includes a bottom plate 1, a positioning frame 2, a plastic-wood formwork 3 and a demoulding assembly 4; the bottom end of the bottom plate 1 is provided with a first groove 10, The upper end is provided with a second groove 11, and the edge of the second groove 11 is provided with a positioning groove 12;

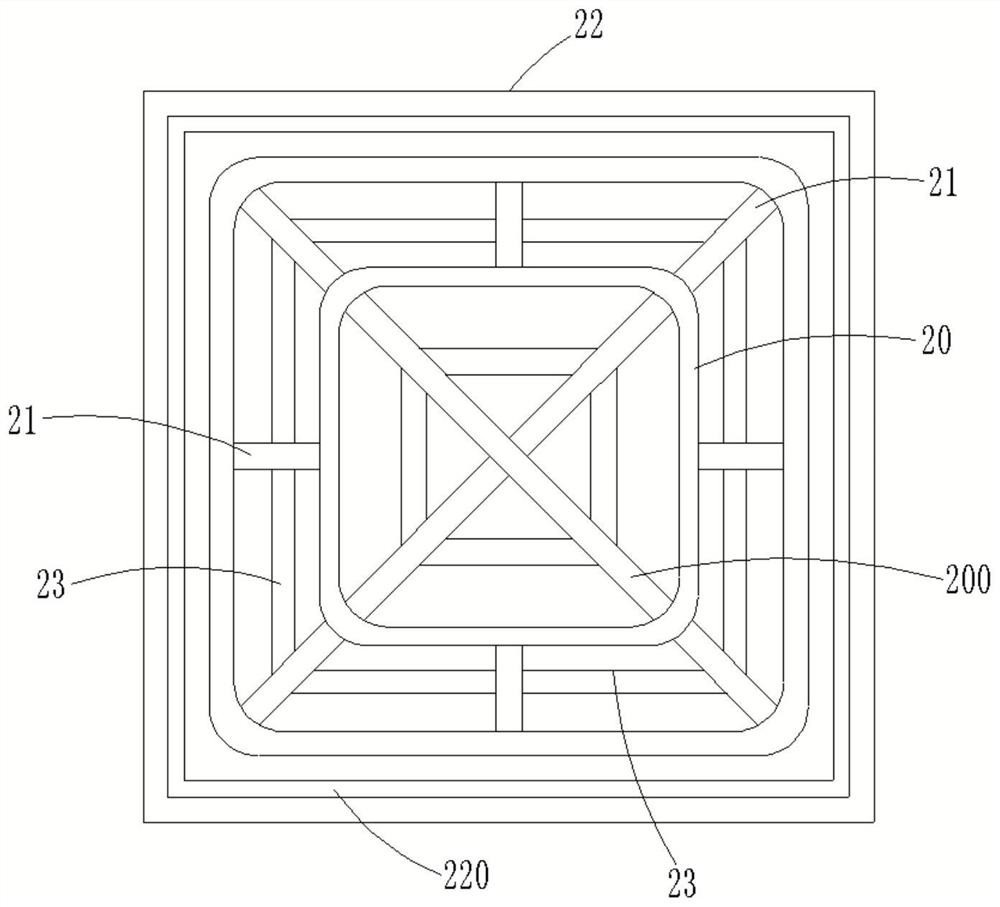

[0038] like figure 1 , 3 , 5, the positioning frame 2 includes a top support ring 20, a side support rod 21 and a limit ring 22, the top support ring 20 is a rectangular structure, and two top beams 200 are crossed inside the top support ring 20; There are 8 rods 21 , each lateral strut 21 is evenly distributed on the lower end surface of the top support ring 20 , the limit ring 22 is movably clamped inside the second groove 11 , and the limit ring 22 is connected to the bottom of each side strut 21 . The ends are fixedly connected, the limit ring 22 has the same structure a...

Embodiment 2

[0042] like figure 1 , 2 A reusable plastic-wood formwork for concrete pouring shown in 4 and 4 includes a bottom plate 1, a positioning frame 2, a plastic-wood formwork 3 and a demoulding assembly 4; the bottom end of the bottom plate 1 is provided with a first groove 10, The upper end is provided with a second groove 11, and the edge of the second groove 11 is provided with a positioning groove 12;

[0043] like figure 1 , 3 , 5, the positioning frame 2 includes a top support ring 20, a side support rod 21 and a limit ring 22, the top support ring 20 is a rectangular structure, and two top beams 200 are crossed inside the top support ring 20; There are 8 rods 21 , each lateral strut 21 is evenly distributed on the lower end surface of the top support ring 20 , the limit ring 22 is movably clamped inside the second groove 11 , and the limit ring 22 is connected to the bottom of each side strut 21 . The ends are fixedly connected, the limit ring 22 has the same structure a...

Embodiment 3

[0047] like figure 1 , 2 A reusable plastic-wood formwork for concrete pouring shown in 4 and 4 includes a bottom plate 1, a positioning frame 2, a plastic-wood formwork 3 and a demoulding assembly 4; the bottom end of the bottom plate 1 is provided with a first groove 10, The upper end is provided with a second groove 11, and the edge of the second groove 11 is provided with a positioning groove 12;

[0048] like figure 1 , 3 , 5, the positioning frame 2 includes a top support ring 20, a side support rod 21 and a limit ring 22, the top support ring 20 is a rectangular structure, and two top beams 200 are crossed inside the top support ring 20; Eight rods 21 are provided, and each lateral strut 21 is evenly distributed on the lower end surface of the top support ring 20 . The ends are fixedly connected, the limit ring 22 has the same structure as the top support ring 20, and the side length is greater than that of the top support ring 20; the lower end of the limit ring 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com