Layered water stop structure for multi-layer aquifer in hydrogeological test

A hydrogeological and aquifer technology, applied in water saving, wellbore/well components, measurement, etc., can solve problems such as failure of normal use of the device, damage of airbags after long-term use, air leakage of the device, etc., to improve practicability, prevent Water is convenient and simple, and the effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

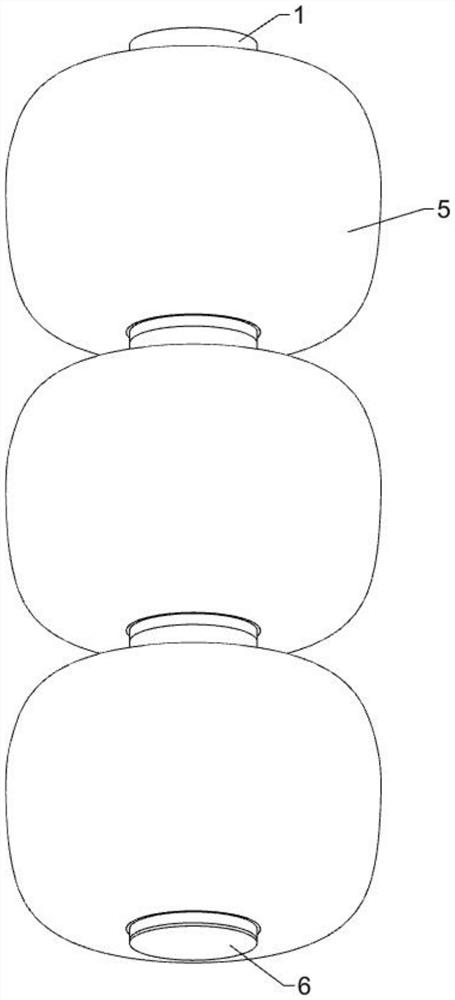

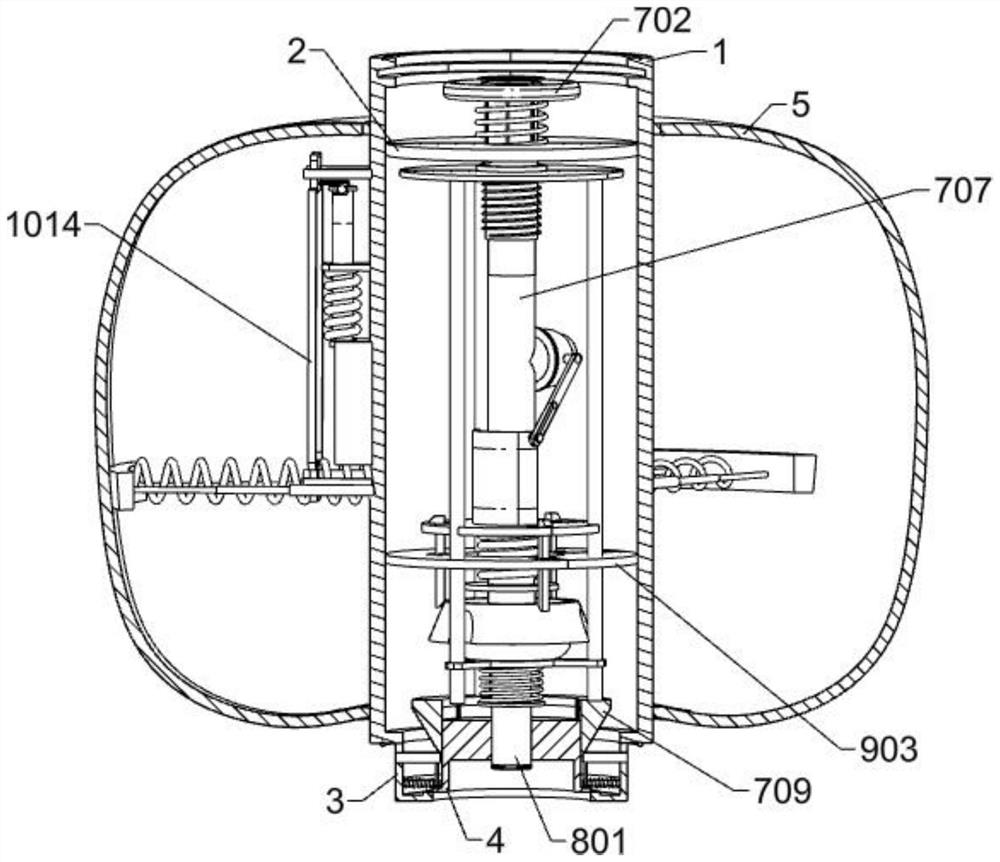

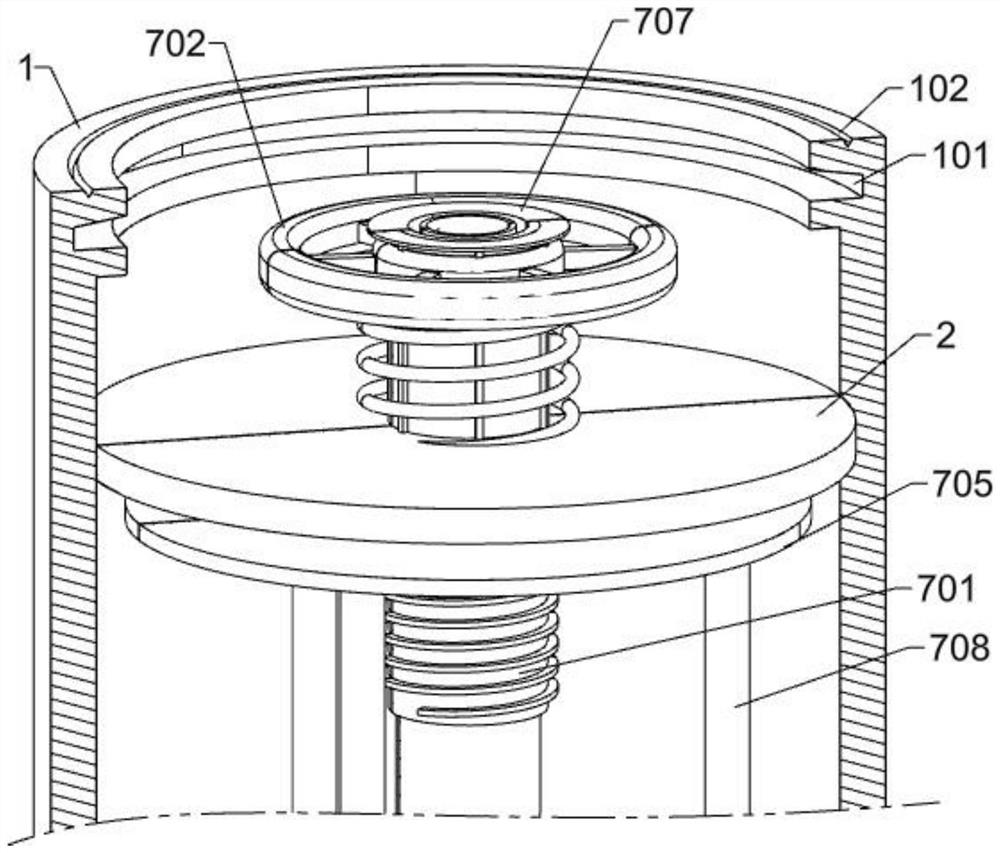

[0031] A multi-layered aquifer layered water-stop structure in a hydrogeological test, such as Figure 1-Figure 11 As shown, there are a plurality of connecting shells 1, the upper part of the inner side of the connecting shell 1 is provided with an annular groove 101, the inner and upper side of the annular groove 101 is provided with an inclined surface, and the upper side of the connecting shell 1 is provided with a prismatic groove 102, the connecting shell A rubber sealing ring is fixed on the lower side of the connecting shell 1, the rubber sealing ring on the lower side of the connecting shell 1 is sealed and matched with the upper prismatic groove 102 of the connecting shell 1 adjacent to the lower side, and a first seal is fixed on the upper part of the inner side of the connecting shell 1. Plate 2, the first sealing plate 2 is located on the lower side of the annular groove 101, the lower side of the connecting shell 1 is fixed with a circular shell 3, the middle of t...

Embodiment 2

[0034] On the basis of Example 1, as Figure 3-Figure 5 As shown, the connecting mechanism includes a rotating sleeve 701, the rotating sleeve 701 is rotatably connected to the middle of the first sealing plate 2, the upper part of the outer side of the rotating sleeve 701 is splined, and the upper part of the outer side of the rotating sleeve 701 is splined connected with a runner 702, The runner 702 is located on the upper side of the first sealing plate 2. The lower side of the runner 702 is fixed with a first annular plate 703. The first annular plate 703 is slidably connected with the rotating sleeve 701. A spring 704, the two ends of the first spring 704 are respectively fixed to the first sealing plate 2 and the first annular plate 703, the lower part of the outer side of the rotating sleeve 701 is threaded, and the lower part of the outer side of the rotating sleeve 701 is threadedly connected with a threaded sleeve 705, a sealing member 706 is provided between the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com