Method for designing well wall of coal-bed gas well

A coalbed methane well and design method technology, applied in the direction of wellbore/well components, earthwork drilling, mining fluid, etc., can solve the problems of easy spalling, restrict desorption and seepage links, reduce the desorption area of coal seam cracks and seepage capacity, etc., to achieve Effect of increasing desorption area, enhancing permeability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

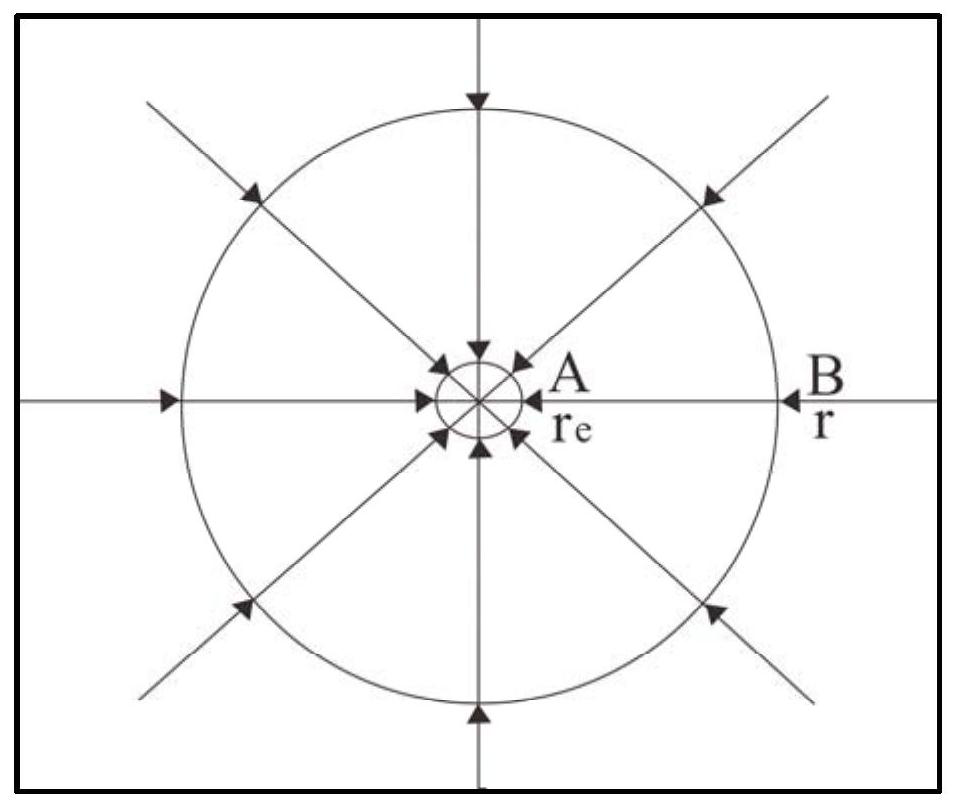

[0025] In one possible implementation environment such as figure 1 shown, assuming figure 1 Among the two concentric circles in the middle, the inner circle (the circle near point A) is near the wellbore in the coalbed methane well, and the outer circle (the circle near point B) is a point outside the discharge radius of the coalbed methane well, with an arrow The straight line is the possible motion trajectory of the fluid in the coal seam. Among them, the fluid in the coal seam includes water and coalbed methane. When fluid flows in coal seam fractures, under the same flow rate, according to Darcy's law, the fluid velocity through point A (near the bottom of the well) will be much greater than the velocity at point B (outside the disc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap