Purge gas ammonia recycling method and ammonia recycler

A technology of ammonia recovery and release gas, which is applied in the preparation/separation of ammonia, and can solve the problems of power consumption, increase of total ammonia, difficult recovery, and utilization of liquid ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

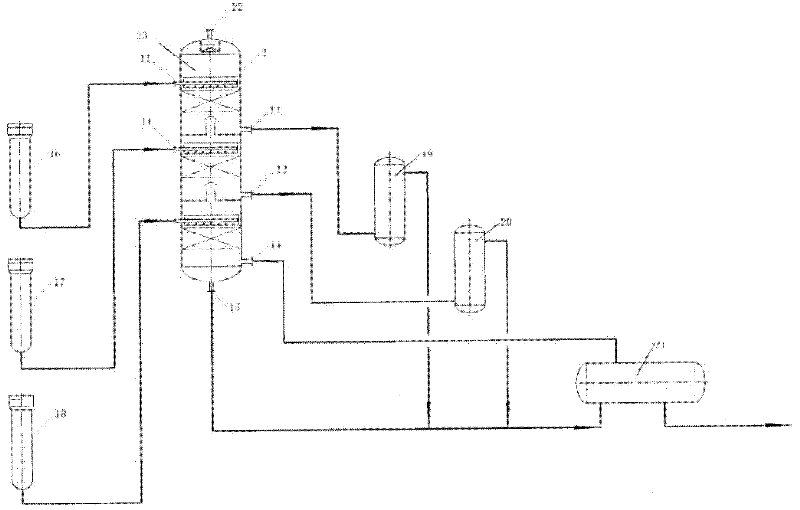

[0056] A. Recovering method of release gas ammonia:

[0057] see figure 2 , the low-temperature liquid ammonia discharged from the ammonia separator 16 after ammonia cooling in the ammonia synthesis process is sent out separately, the cold liquid ammonia discharged from the ammonia separator 17 after the cold exchange, and the normal temperature liquid ammonia discharged from the ammonia separator 18 after the water cooler are also sent separately, or Send out the mixed liquid ammonia after mixing cold liquid ammonia and normal temperature liquid ammonia, or the ammonia synthesis process still follows the traditional ammonia discharge process, that is, the liquid ammonia discharged from each ammonia separator in the ammonia synthesis process is combined and then sent out, but the released gas ammonia The recovery effect and the cold recovery effect are poor.

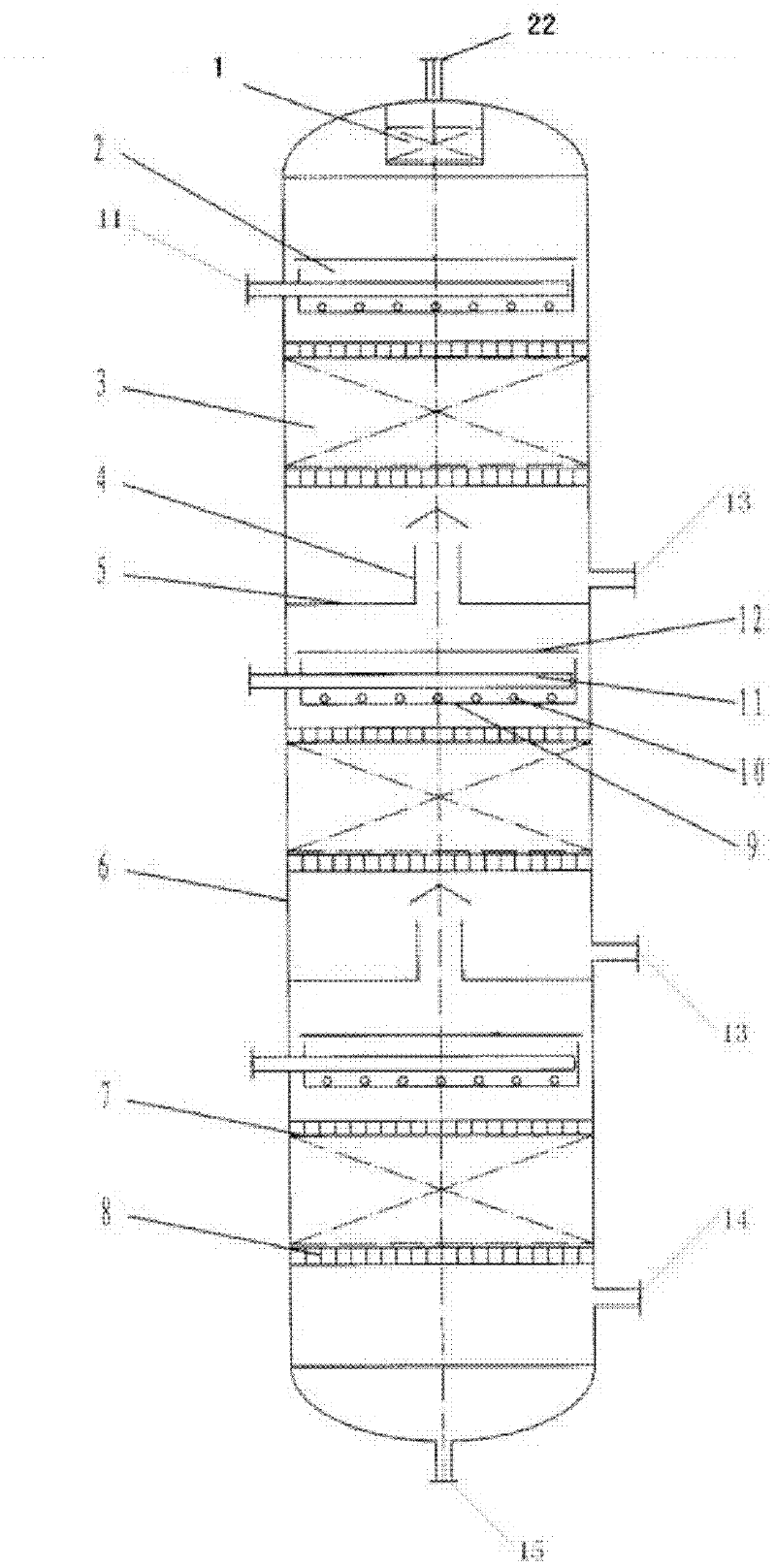

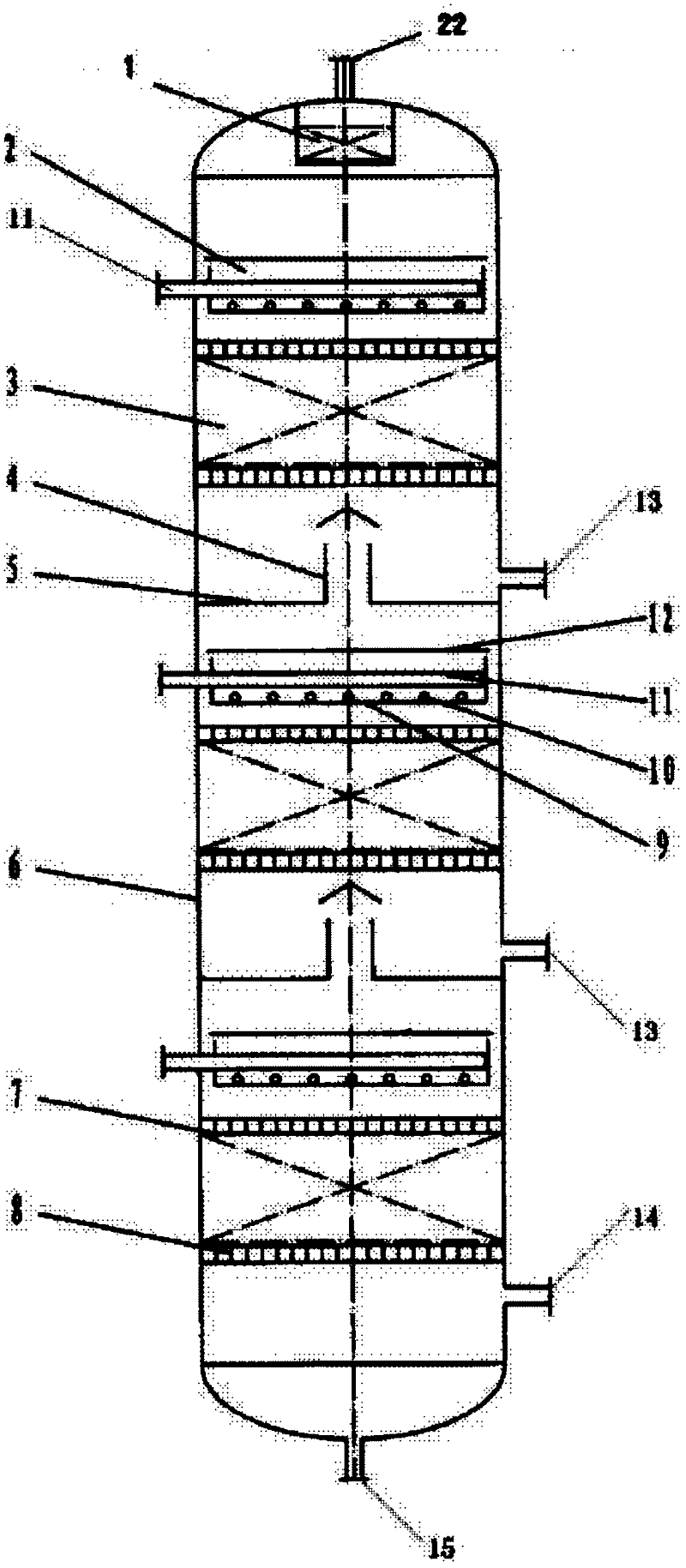

[0058] see figure 1 , an ammonia recoverer 23 is added between the ammonia synthesis process and the liquid ammonia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com