Self-unblocking sewage pump based on flexible pump body

A sewage pump and pump body technology, which is applied to the components of the pumping device for elastic fluid, the pump with flexible working elements, and the general water supply saving, etc. , Improve the effect of pumping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

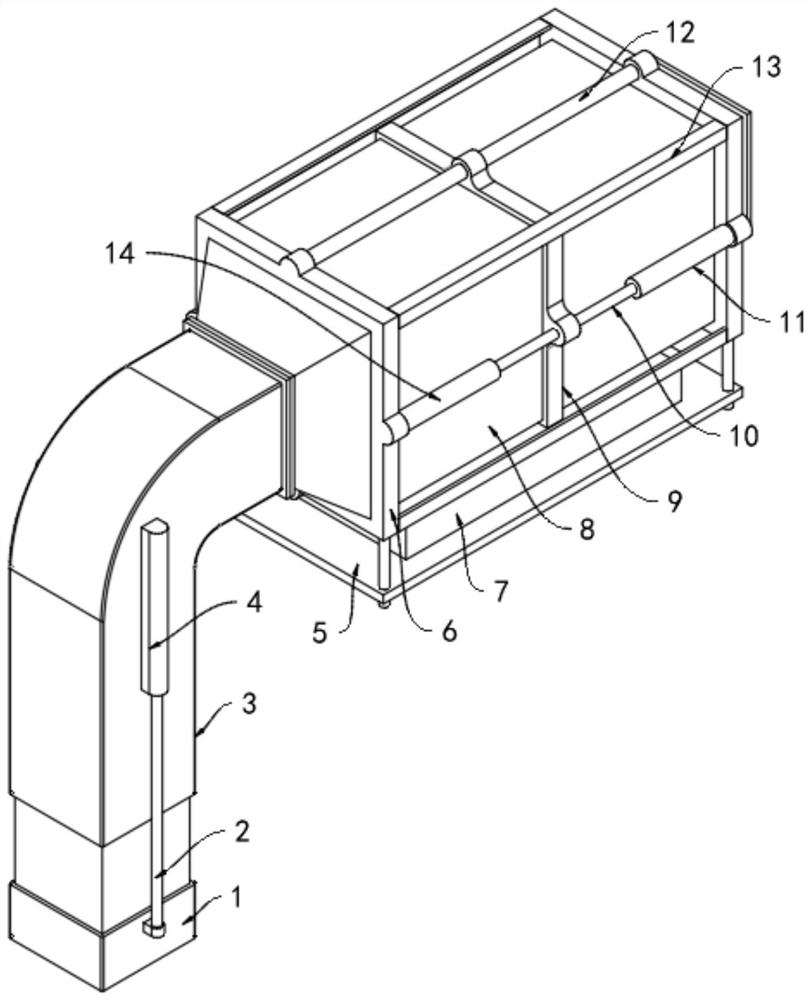

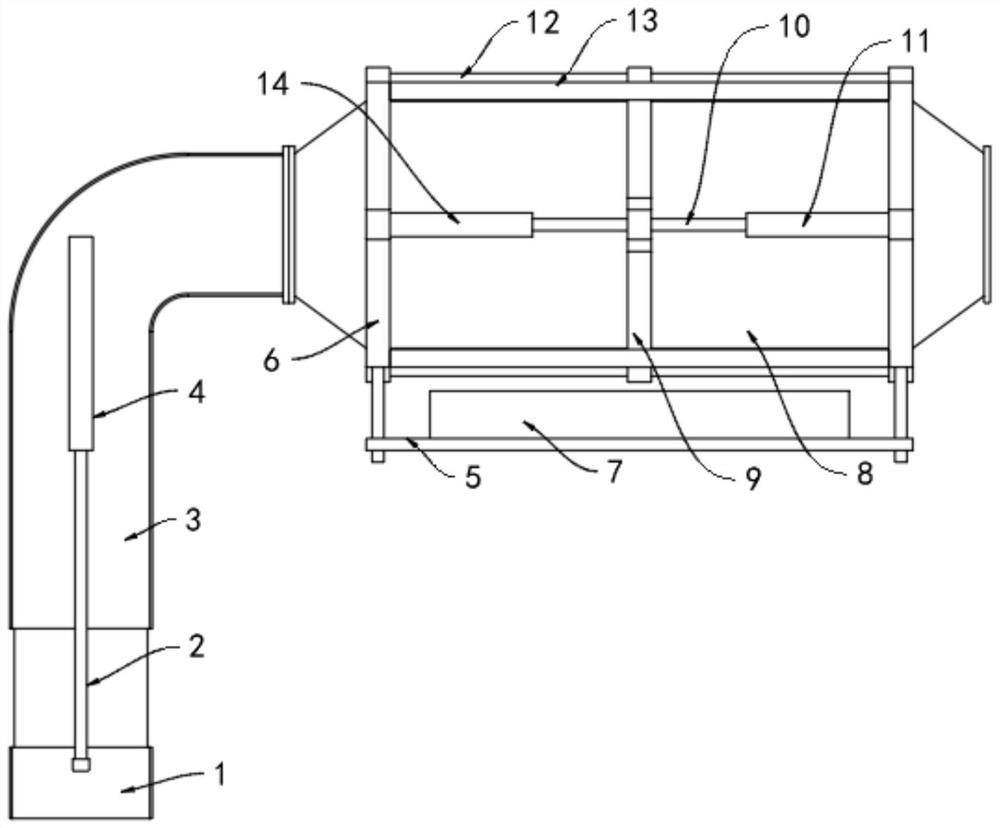

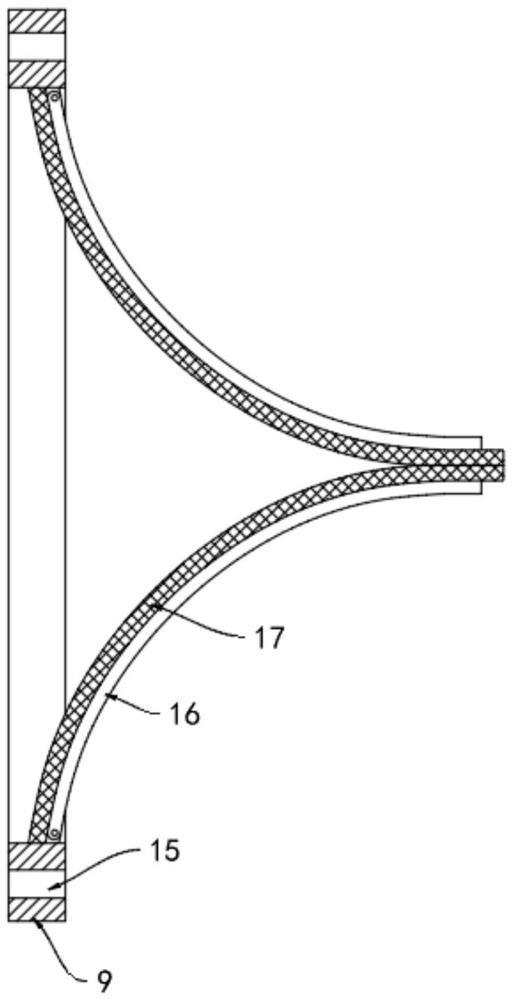

[0027] like Figure 1-4 As shown, the embodiment of the present invention provides a self-cleaning type sewage pump based on a flexible pump body, including a frame 6, the frame 6 is in the shape of a long direction, and is arranged symmetrically on the left and right, and the frame 6 includes connecting sections arranged on the left and right sides, The connecting section is used to connect the water inlet pipe and the water outlet pipe. Several angle steels 13 are fixedly connected between the two connecting sections, and the angle steels 13 are fixed at the corners of the connecting section to realize the fixed connection of the two connecting sections. The inner side of the frame 6 is provided There is a flexible tube 8, the flexible tube 8 is made of rubber or silicone, so that the flexible tube 8 can be bent, and its specific structure can also be similar to a bellows, to ensure that the flexible tube 8 can be stretched or compressed in the axial direction, and the flexib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com