Cooling triangular unit of flow-equalizing louver with louver blades capable of rotating vertically

A technology for cooling triangles and shutters, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as increased ventilation resistance, reduce ventilation resistance, improve heat exchange performance, Optimizing the effect of ambient wind distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 is a cooling triangular unit with an equalizing louver with louvers that can be rotated vertically at a small ambient wind speed.

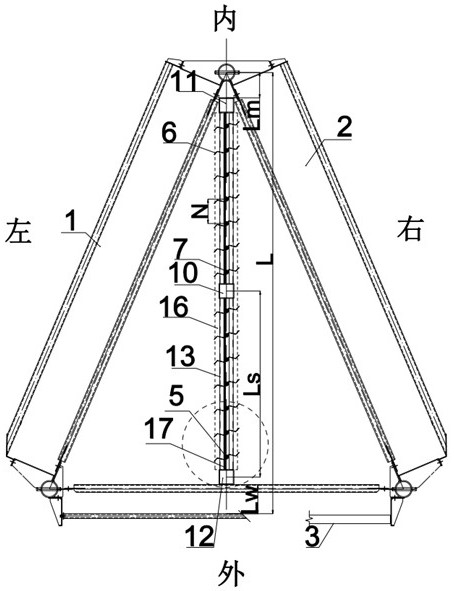

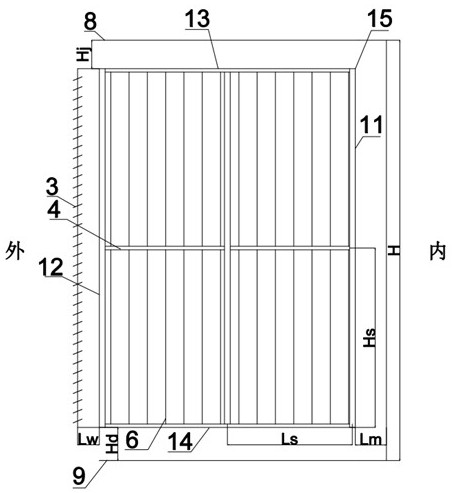

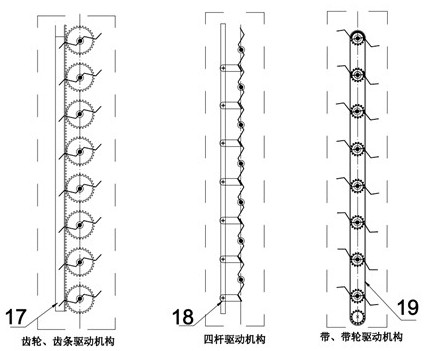

[0026] like Figure 4 As shown in the figure, the present invention is a cooling triangular unit with a vertical rotatable flow equalizing louver, including a cooling triangular unit and a vertical rotatable flow equalizing louver, the cooling triangular unit includes a left cooling column 1, a right cooling The column 2 and the air inlet louver 3, the louver can rotate vertically and the flow louver 16 includes the louver fixing device 15, the vertical rotating louver 6 and the actuator 7, and the louver can be rotated vertically. The flow louver 16 is vertical along the cooling triangle unit The central symmetry plane is arranged vertically. The right end of the left cooling column 1 is provided with a supporting surface, the left end of the right cooling column 2 is provided with a supporting surface, the right end supporti...

Embodiment 2

[0027] Embodiment 2 is a cooling triangular unit with a vertical rotatable flow equalizing louver when the ambient wind speed is large and the deviation angle of the air inlet is small.

[0028] like Figure 5 As shown in the figure, the present invention is a cooling triangular unit with a vertical rotatable flow equalizing louver, including a cooling triangular unit and a vertical rotatable flow equalizing louver. The cooling triangular unit includes a left cooling column 1, a right cooling The column 2 and the air inlet louver 3, the louver can rotate vertically and the flow louver 16 includes the louver fixing device 15, the vertical rotating louver 6 and the actuator 7, and the louver can be rotated vertically. The flow louver 16 is vertical along the cooling triangle unit The central symmetry plane is arranged vertically. The right end of the left cooling column 1 is provided with a supporting surface, the left end of the right cooling column 2 is provided with a suppor...

Embodiment 3

[0029] Embodiment 3 is a cooling triangular unit with an equalizing louver with louvers that can be rotated vertically when the ambient wind speed is large and the deviation angle of the inlet air is relatively large.

[0030] like Image 6As shown in the figure, the present invention is a cooling triangular unit with a vertical rotatable flow equalizing louver, including a cooling triangular unit and a vertical rotatable flow equalizing louver, the cooling triangular unit includes a left cooling column 1, a right cooling The column 2 and the air inlet louver 3, the louver can rotate vertically and the flow louver 16 includes the louver fixing device 15, the vertical rotating louver 6 and the actuator 7, and the louver can be rotated vertically. The flow louver 16 is vertical along the cooling triangle unit The central symmetry plane is arranged vertically. The right end of the left cooling column 1 is provided with a supporting surface, the left end of the right cooling colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com