Series assembly equipment and method for solar cell silicon wafers

A technology of solar cells and battery silicon wafers, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of limited welding space, inconvenient serial assembly of silicon wafers, etc., and achieve the effect of achieving tightness and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. The embodiments of the present invention are presented for purposes of illustration and description, and are not intended to be exhaustive or to limit the invention to the forms disclosed. Many modifications and variations will be apparent to those of ordinary skill in the art. The embodiment was chosen and described in order to better explain the principles of the invention and the practical application, and to enable others of ordinary skill in the art to understand the invention for various embodiments with various modifications as are suited to the particular use.

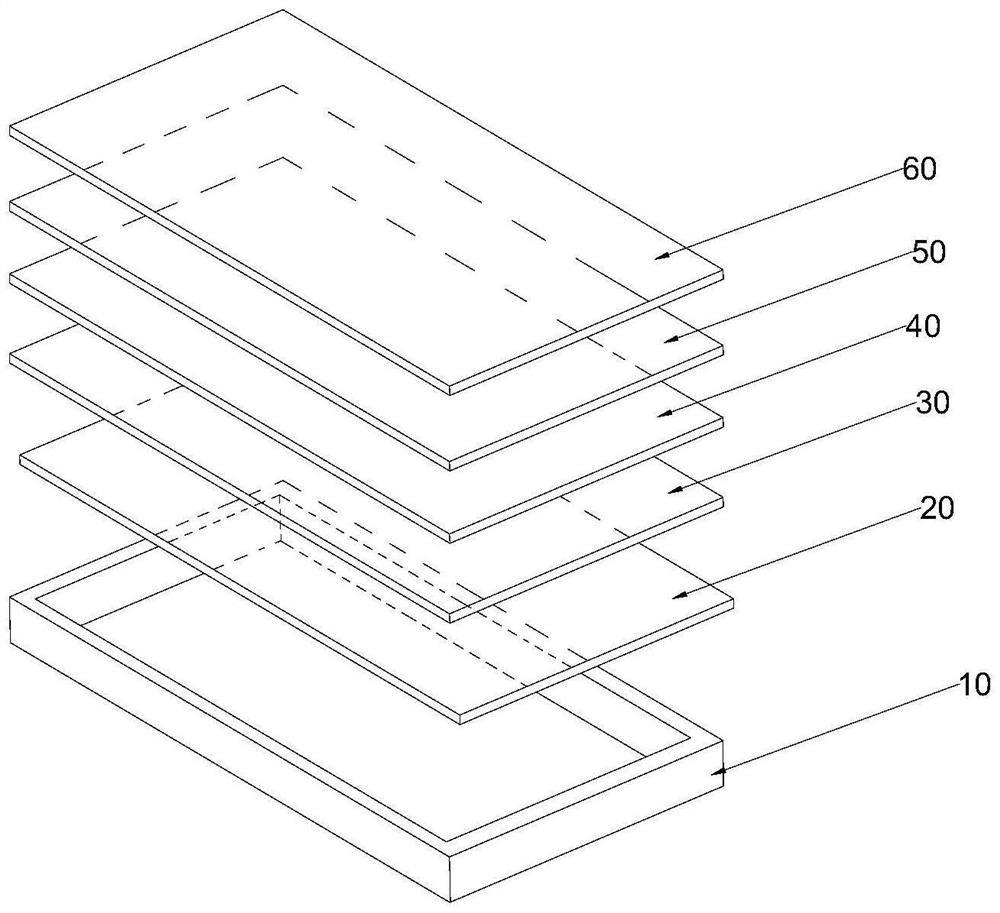

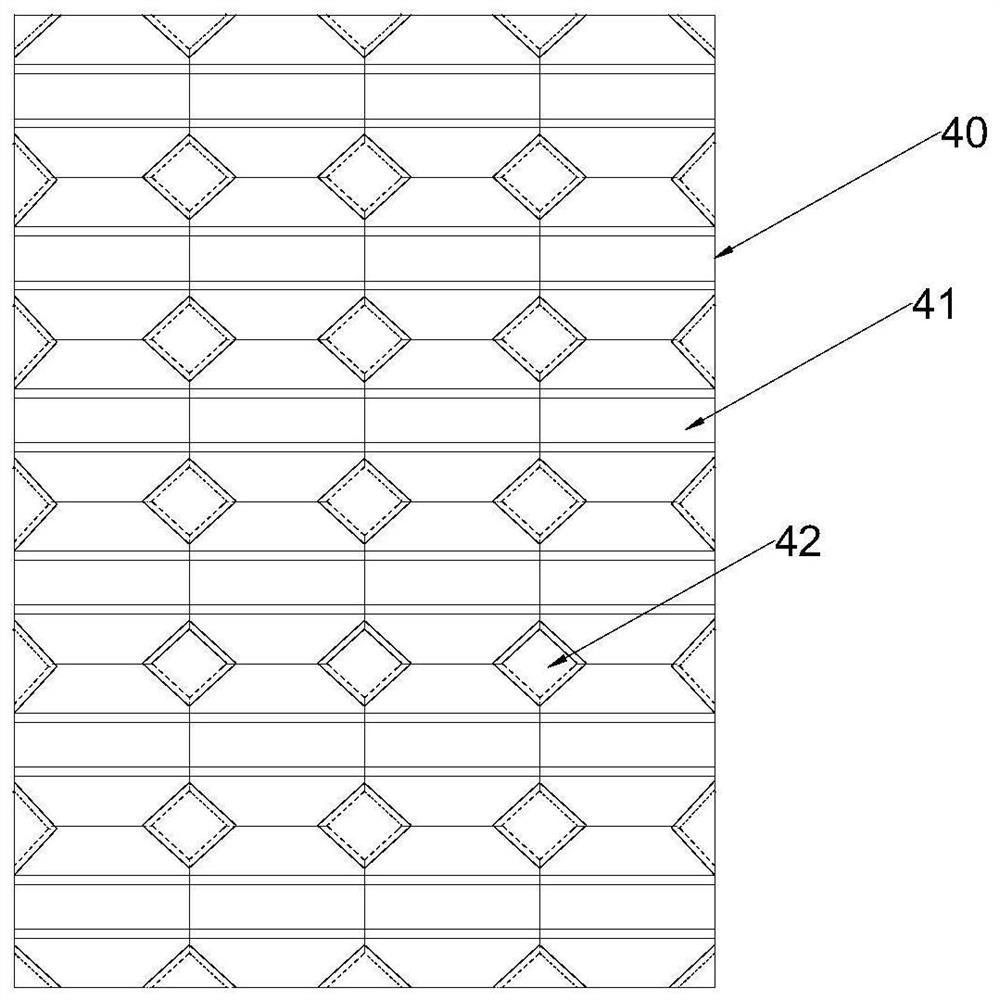

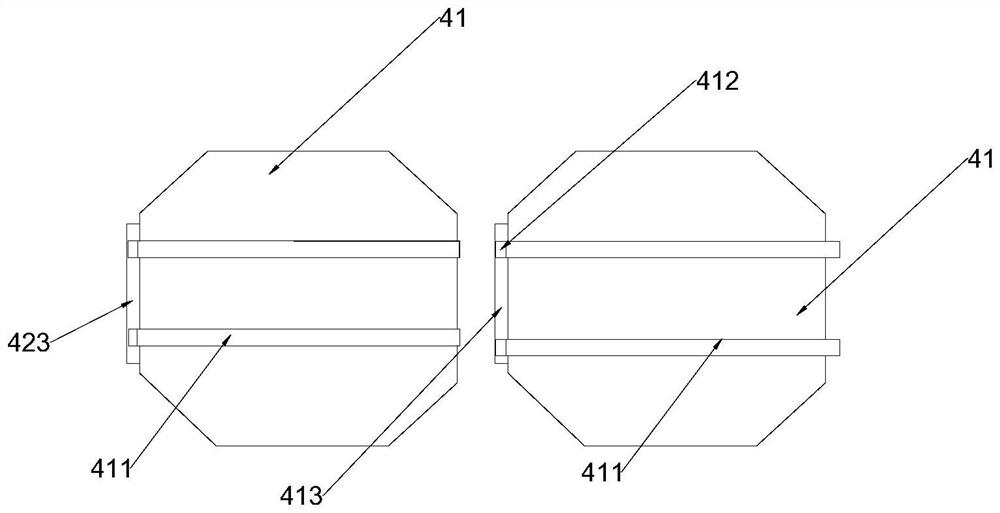

[0034] see Figure 1-Figure 8 , In the embodiment of the present invention, a solar cell silicon wafer serial assembly device and method, wherein the assembly device includes an aluminum alloy frame 10, a back plate 20, a first EVA board 30, a battery silicon wafer board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com