Cable protection box for electrical engineering

A technology of electrical engineering and protection box, applied in electrical components, climate change adaptation, fire rescue, etc., to facilitate maintenance, reduce the probability of burnout, and avoid fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

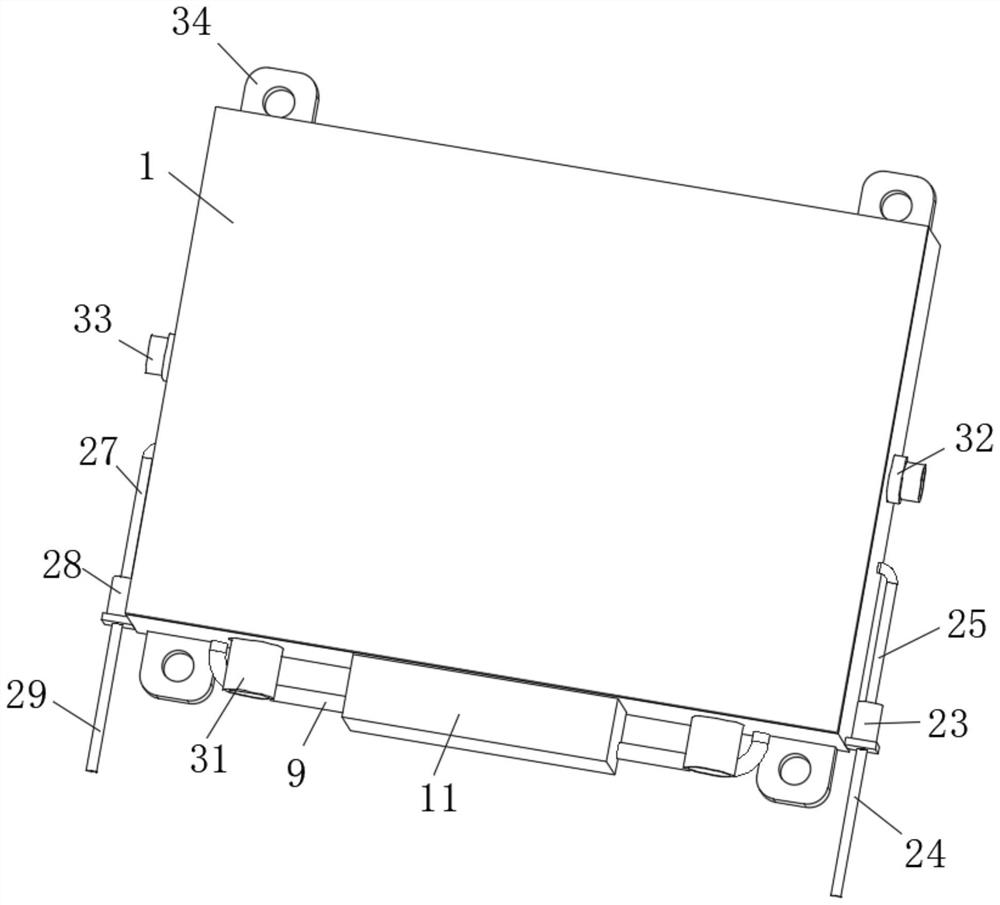

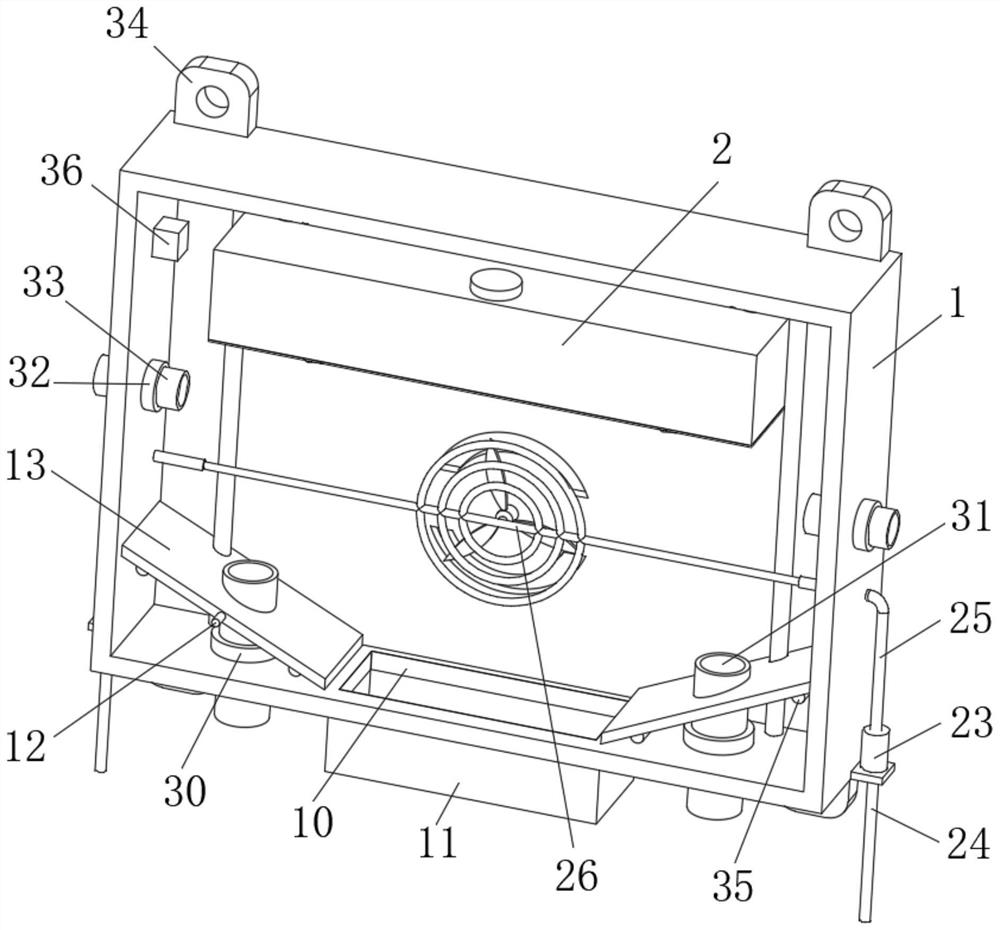

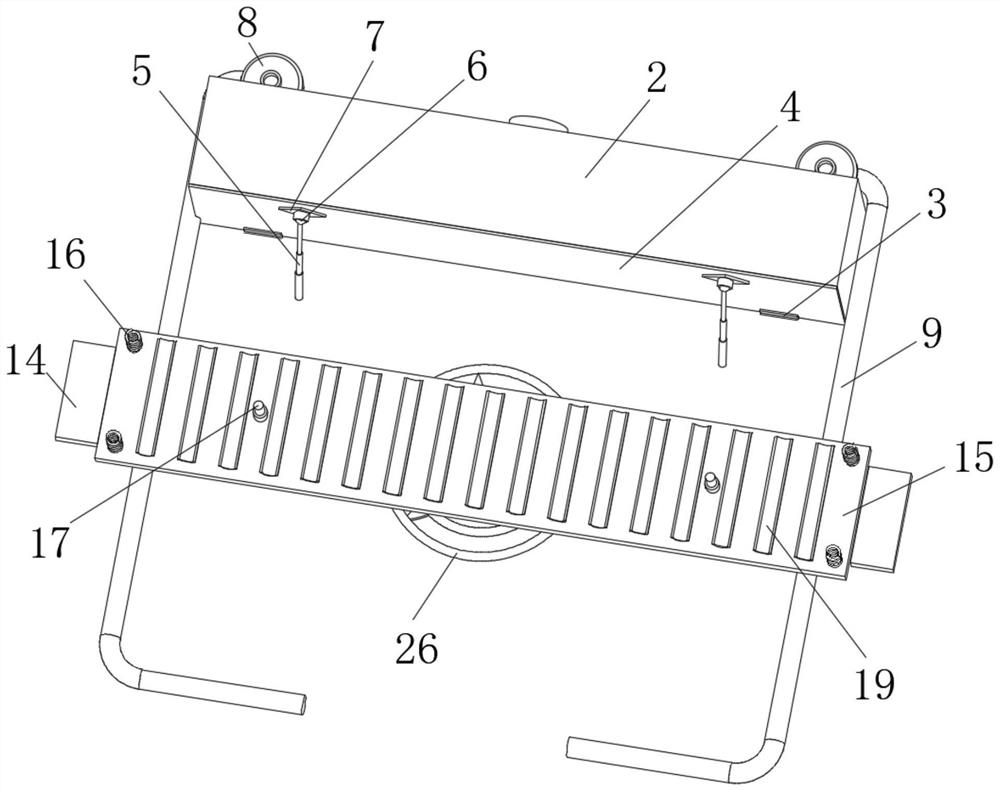

[0028] see Figure 1-7 As shown, the present invention provides a technical solution: a cable protection box for electrical engineering, comprising a protection box 1 and a first mounting plate 15, the inner wall of the protection box 1 is fixedly connected with a dry powder box 2, and the outer wall of the dry powder box 2 is provided with There is a hinge 3, the outer wall of the hinge 3 is hinged with a bottom plate 4, the bottom outer wall of the bottom plate 4 is fixedly connected with a mounting seat 7, the inner wall of the mounting seat 7 is provided with a rotating ball 6, and the inner wall of the protection box 1 is fixedly connected with an electric push rod 5 , the end of the electric push rod 5 away from the protection box 1 is fixedly connected with the outer wall of the rotating ball 6, the top outer wall of the dry powder box 2 is fixedly connected with a negative pressure machine 8, and the input end of the negative pressure machine 8 is fixedly connected with...

Embodiment 2

[0031] see Figure 1-7 As shown, on the basis of the first embodiment, the present invention provides a technical solution: the outer walls on both sides of the first installation plate 15 are fixedly connected with the fixing plates 14, and the outer wall of the fixing plate 14 away from the first installation plate 15 is connected to the outer wall of the side. The inner wall of the protection box 1 is fixedly connected, the outer wall of the first mounting plate 15 is fixedly connected with a spring 16, the end of the spring 16 away from the first mounting plate 15 is fixedly connected with a second mounting plate 18, and the outer wall of the first mounting plate 15 is fixedly connected with a second mounting plate 18. The telescopic rod 17, the end of the telescopic rod 17 away from the first mounting plate 15 is fixedly connected to the outer wall of the second mounting plate 18, and the outer wall of the first mounting plate 15 and the second mounting plate 18 close to e...

Embodiment 3

[0034] see Figure 1-7As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a motor 20 is fixedly connected to the inner wall of the protection box 1 , a fan 22 is fixedly connected to the output end of the motor 20 , and the outer wall of the protection box 1 is fixedly connected with a fan 22 . A heat dissipation groove 21 is opened on the outer side of the motor 20 , a first water pump 23 is fixedly connected to one outer wall of the protection box 1 , the input end of the first water pump 23 is fixedly connected with a first water pipe 24 , and the output end of the first water pump 23 is fixed A second water pipe 25 is connected, the end of the second water pipe 25 away from the first water pump 23 is fixedly connected with a through-flow pipe 26, and the outer wall of the protection box 1 away from the first water pump 23 is fixedly connected with a second water pump 28, the second water pump 28 The input end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com