Automatic two-component coating spraying robot for steel bridge deck and spraying method

A spraying robot and automatic spraying technology, applied in the direction of manipulators, spraying devices, manufacturing tools, etc., can solve the problems of large site limitations, low efficiency, fast solidification, etc., and achieve the effect of efficient walking, improved efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

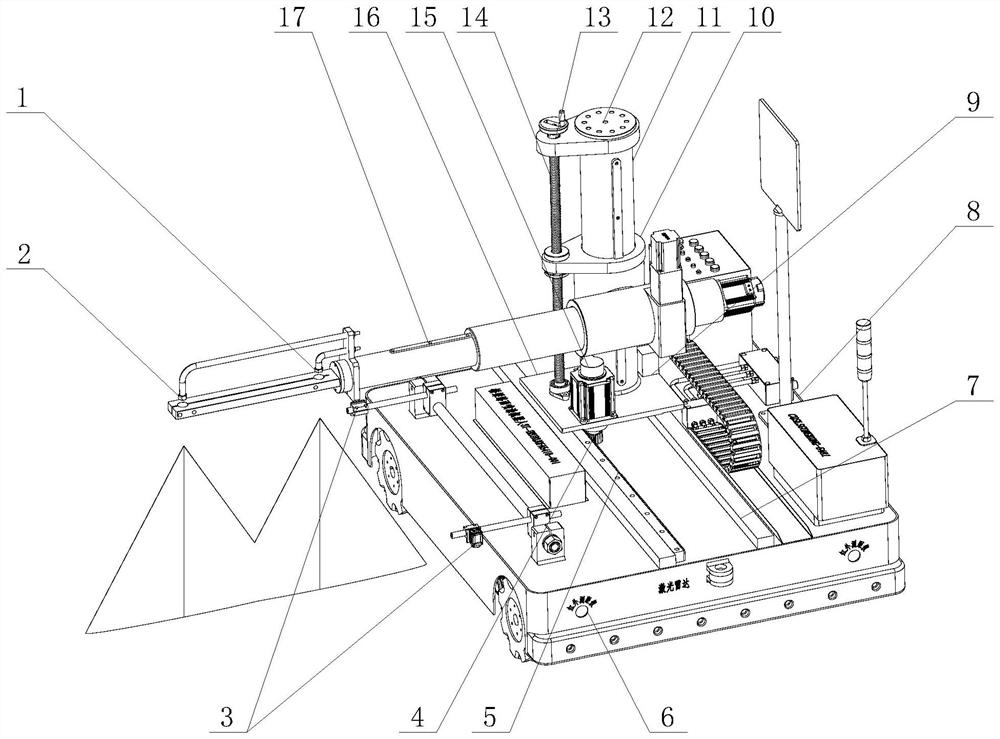

[0017] Embodiment 1 of the present invention: a two-component paint automatic spraying robot for steel bridge deck, comprising a mobile base 8, the bottom of the mobile base 8 is equipped with a Mecanum wheel, a power system of the Mecanum wheel and the mobile base 8 Transmission connection; there is a translation track 7 on the mobile base 8, a translation platform 16 is arranged on the translation track 7, a lifting device 10 is installed on the translation platform 16, and a horizontally arranged telescopic rod 17 is installed on the lifting end 11 of the lifting device 10, and the telescopic A first spray head 1 and a second spray head 2 are installed on the rod 17. The first spray head 1 communicates with the first paint spray box through the pump body, and the second spray head 2 communicates with the second paint spray box through the pump body. The front end and the rear end of the mobile base 8 are respectively installed with a thickness measuring device 3 facing downw...

Embodiment 2

[0018] Embodiment 2: a kind of automatic spraying robot for steel bridge deck two-component paint, including mobile base 8, the bottom of mobile base 8 is equipped with Mecanum wheel, and the power system transmission connection of Mecanum wheel and mobile base 8; The mobile base 8 is provided with a translation track 7, a translation platform 16 is provided on the translation track 7, a lifting device 10 is installed on the translation platform 16, and a horizontally arranged telescopic rod 17 is installed on the lifting end 11 of the lifting device 10. A first spray head 1 and a second spray head 2 are installed, the first spray head 1 communicates with the first paint spray box through the pump body, and the second spray head 2 communicates with the second paint spray box through the pump body. The front end and the rear end of the mobile base 8 are respectively installed with a thickness measuring device 3 facing downward. The controller is electrically connected, and the ...

Embodiment 3

[0020] Embodiment 3: a kind of automatic spraying robot for steel bridge deck two-component paint, including mobile base 8, the bottom of mobile base 8 is equipped with Mecanum wheel, and the power system transmission connection of Mecanum wheel and mobile base 8; The mobile base 8 is provided with a translation track 7, a translation platform 16 is provided on the translation track 7, a lifting device 10 is installed on the translation platform 16, and a horizontally arranged telescopic rod 17 is installed on the lifting end 11 of the lifting device 10. A first spray head 1 and a second spray head 2 are installed, the first spray head 1 communicates with the first paint spray box through the pump body, and the second spray head 2 communicates with the second paint spray box through the pump body. The front end and the rear end of the mobile base 8 are respectively installed with a thickness measuring device 3 facing downward. The controller is electrically connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com