Height shaping and adjusting clamp for cold heading thin-wall sleeve part

A casing and thin-walled technology is applied in the field of height shaping and adjusting fixtures for cold heading thin-walled casing parts, which can solve the problem that the finished product cannot reach the pre-determined precision, and achieve the effect of increasing the force-bearing area and enhancing the cleaning effect. tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

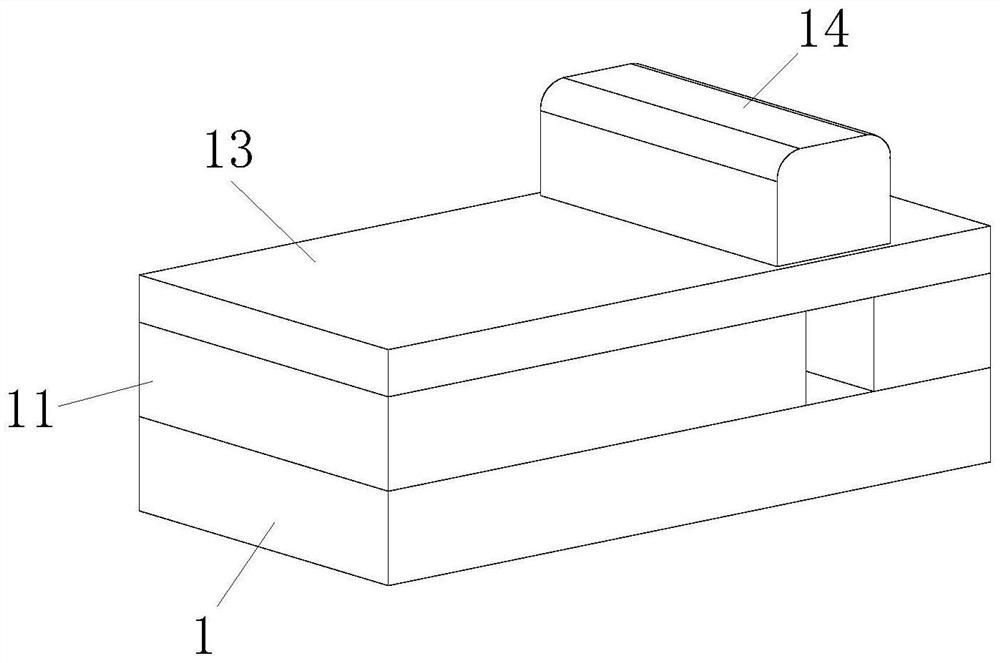

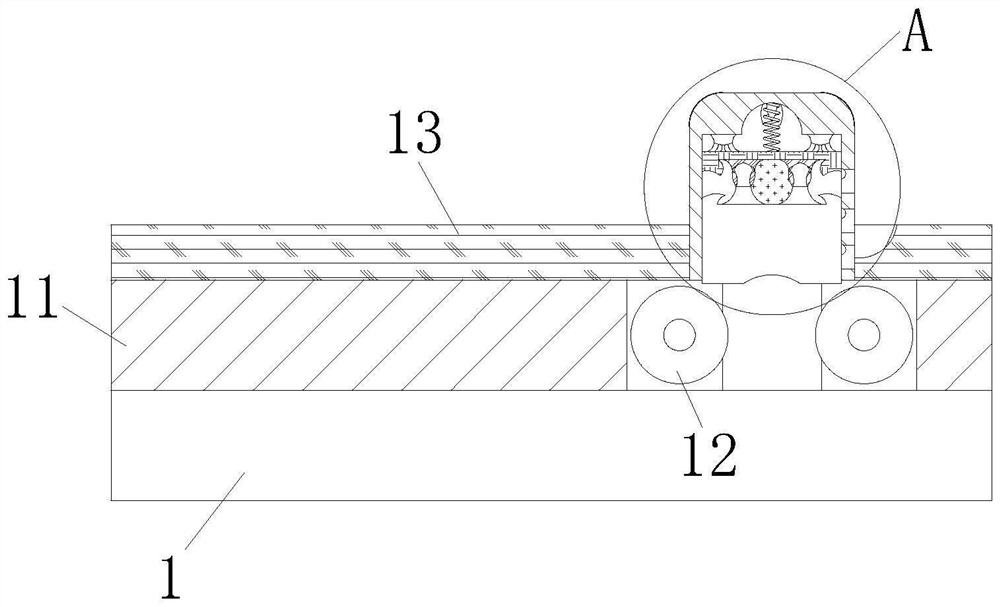

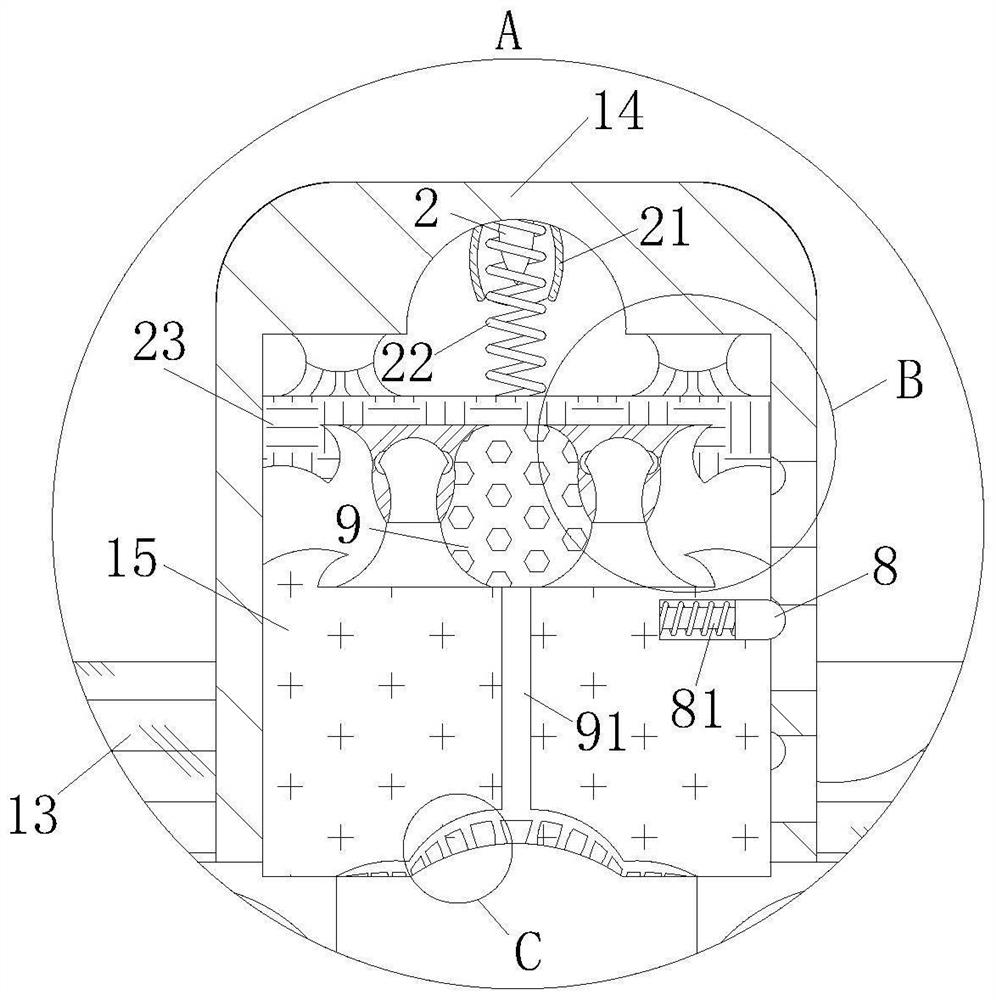

[0030] see Figure 1-6 As shown, a height shaping adjustment fixture for cold heading thin-walled casing parts includes a base bottom plate 1 and an adjustment unit; the adjustment unit is arranged at the end of the base bottom plate 1; the end of the base bottom plate 1 A guide plate 11 is fixedly connected; the inner side wall of the guide plate 11 is rotatably connected with two sets of righting bullets 12; the adjustment unit includes a height-limiting cover plate 13, a height-limiting shaping block 14, a sliding pressure plate 15 and an auxiliary mechanism; The height-limiting cover plate 13 is arranged at the end of the righting bullet 12 ; the height-limiting shaping block 14 is fixedly connected to the inner side wall of the height-limiting cover plate 13 ; the sliding pressure plate 15 is slidably connected to the inner side of the height-limiting shaping block 14 The bottom end of the sliding pressing plate 15 is provided with an arc-shaped groove; the auxiliary mech...

Embodiment 2

[0040] see Figure 7 As shown, in Comparative Example 1, as another embodiment of the present invention, the bottom end of the sliding pressure plate 15 is fixedly connected with a friction pad 98; the shape of the friction pad 98 corresponds to the bottom end of the sliding pressure plate 15; During operation, the friction pad 98 at the bottom end of the sliding pressure plate 15 is pressed against the end of the sleeve, and the friction pad 98 protects the sleeve and prevents friction to the bottom side wall of the sliding pressure plate 15 .

[0041] Working principle, when working, the staff puts the sleeve into the side wall of the guide plate 11, and is located between the two sets of righting warheads 12, and the height-limiting cover plate 13 is driven by the electric cylinder to press down on the end of the guide plate 11. position, the sliding pressure plate 15 inside the height-limiting shaping block 14 is pressed against the end of the casing, and cooperates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com