Full-automatic feeding, oiling and assembling integrated assembling machine

A fully automatic and assembly machine technology, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low production efficiency, difficulty in assembling silicone and caps, and inability to ensure the consistency of parts, so as to improve the working environment, The effect of automatic oiling is stable and the operation is convenient for employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

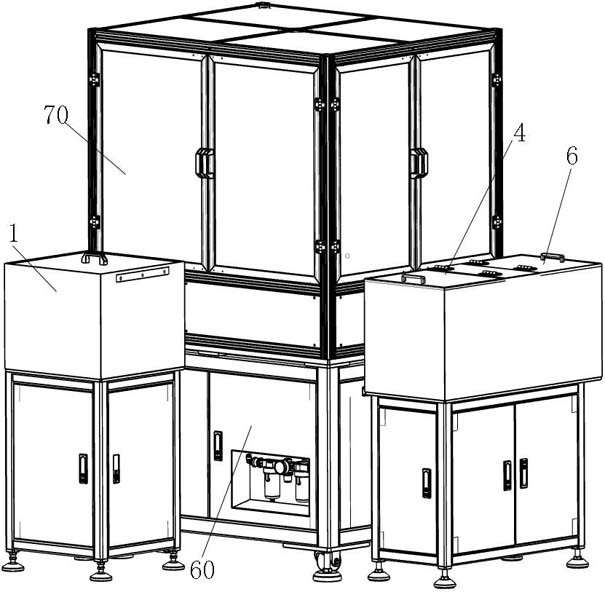

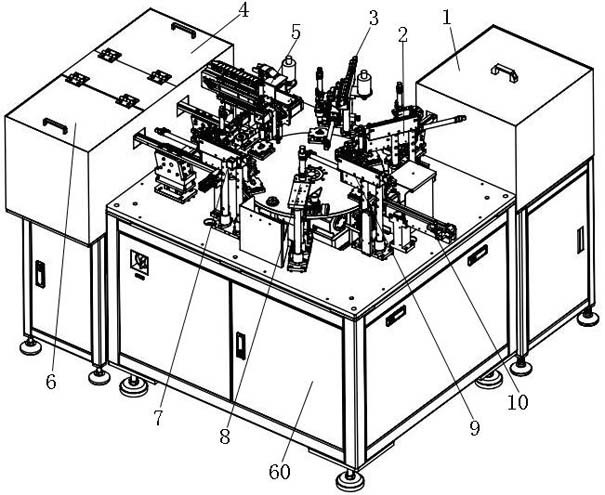

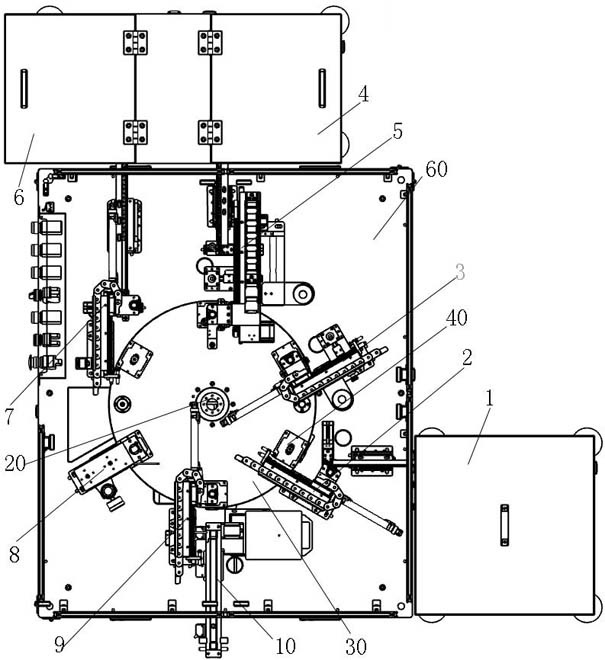

[0038] like Figure 1-4 The fully automatic feeding, oiling, and assembling integrated assembly machine shown here includes cylindrical parts feeding vibrating plate 1, cylindrical parts feeding unit 2, automatic silicone oil dipping unit 3, silica gel feeding vibrating plate 4, silica gel feeding assembly Unit 5, cap feeding vibrating plate 6, cap feeding unit 7, cap riveting unit 8, product unloading unit 9, qualified product unloading belt line 10, divider 20, rotating disc 30, a set of cylindrical parts positioning tooling and The divider 20 can drive the rotary disk 30 to rotate 360°. The cylindrical parts feeding unit 2, the automatic silicone oil dipping unit 3, the silica gel feeding and assembling unit 5, the cap feeding unit 7, the cap riveting unit 8, the product unloading The unit 9, the unloading belt line 10 for qualified products and the jacking assembly 50 are all arranged on the machine table 60, and the cylindrical parts feeding unit 2, the automatic silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com