Adjustable mechanical hydraulic packing machine for production line

A mechanical hydraulic and adjustable technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of unadjustable extrusion depth and inconvenient unloading, so as to avoid material scatter, reduce trouble, and speed up unloading time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

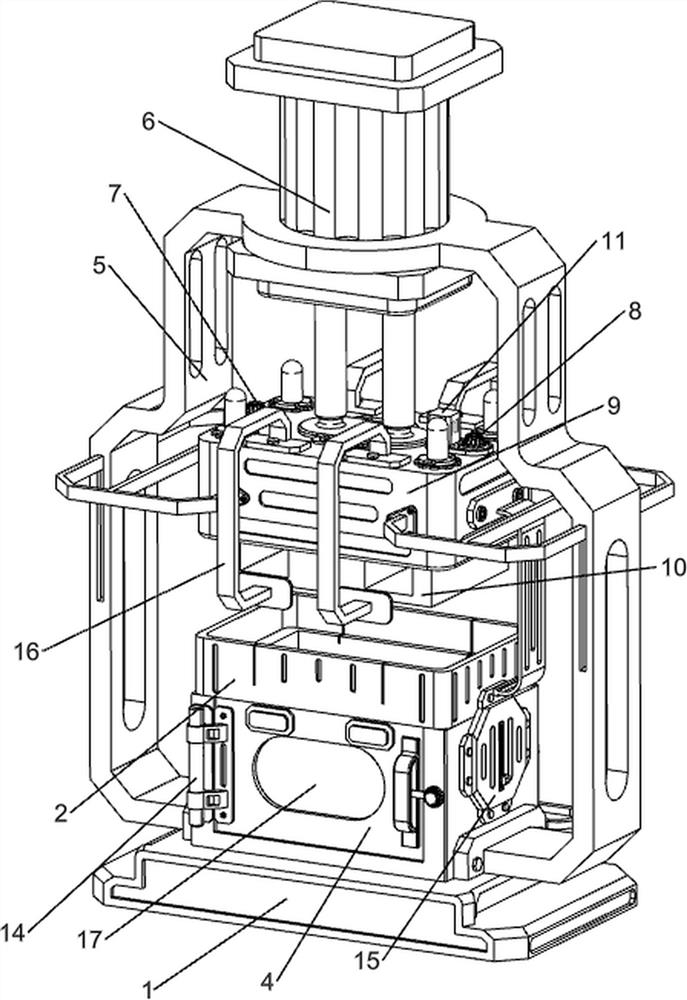

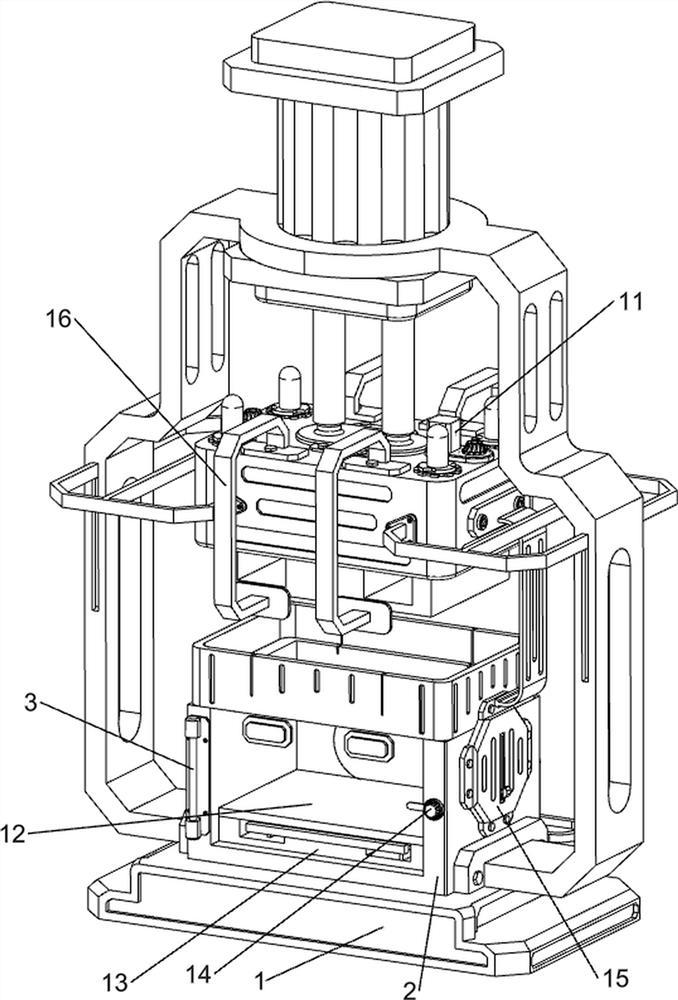

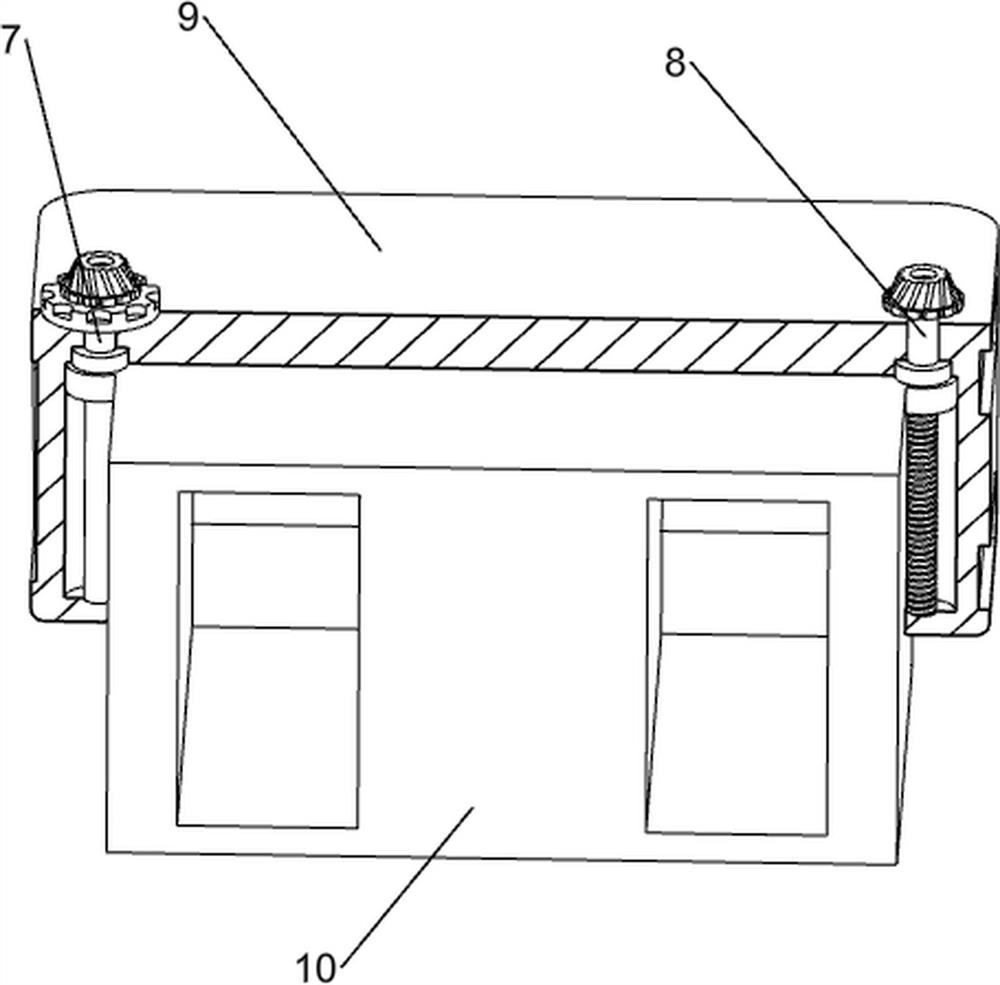

[0041] An adjustable mechanical hydraulic baler for production line, in Figure 1-3As shown in the figure, it includes a base plate 1, a placing frame 2, a rotating shaft 3, a protective door 4, a limit frame 5, a hydraulic cylinder 6, a guide rod 7, a threaded rod 8, a guide shell 9, a pressing block 10, a transmission mechanism 11, a collection The mechanism 12 and the transparent plate 17, the top of the bottom plate 1 is bolted with a placing frame 2, the left side of the placing frame 2 is symmetrically connected with a rotating shaft 3 through bolts, and the rotating shaft 3 is equipped with a rotating protective door 4, and the protective door 4 is connected with the placing frame. 2 contact, a transparent plate 17 is arranged in the middle of the protective door 4, a limit frame 5 is connected between the left and right side walls of the placing frame 2, a hydraulic cylinder 6 is installed on the upper part of the limit frame 5, and the bottom of the two telescopic rods...

Embodiment 2

[0047] On the basis of Example 1, in figure 2 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 It also includes a snap mechanism 13, and the snap mechanism 13 includes a support plate 130, a top block 131, a wedge rod 132, a return spring 133, a snap plate 134, a return spring 135 and a connecting frame 136, which are placed in the frame 2 A support plate 130 is welded at the bottom, a top block 131 is provided on the inner side of the lower part of the protective door 4, and wedge-shaped rods 132 are slidably provided on the left and right sides of the support plate 130. A return spring 133 is connected between the rod 132 and the interior of the support plate 130 , the left and right sides of the support plate 130 are slidably provided with a clamping plate 134 that can play a fixed role, and the wedge-shaped rods 132 are slidingly matched with the adjacent clamping plates 134 Two return springs 135 are connected between the clamping plate 134 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com