Degradable thermal shrinkage film, degradable thermal shrinkage multilayer film and preparation method of degradable thermal shrinkage multilayer film

A heat-shrinkable film and multi-layer film technology, applied in chemical instruments and methods, sustainable manufacturing/processing, lamination, etc., can solve the problem of heat shrinkability of degradable polyester film, insufficient melt strength and water vapor barrier properties, etc. Problems, achieve good fullness, improve barrier properties, and increase the effect of water vapor penetration paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

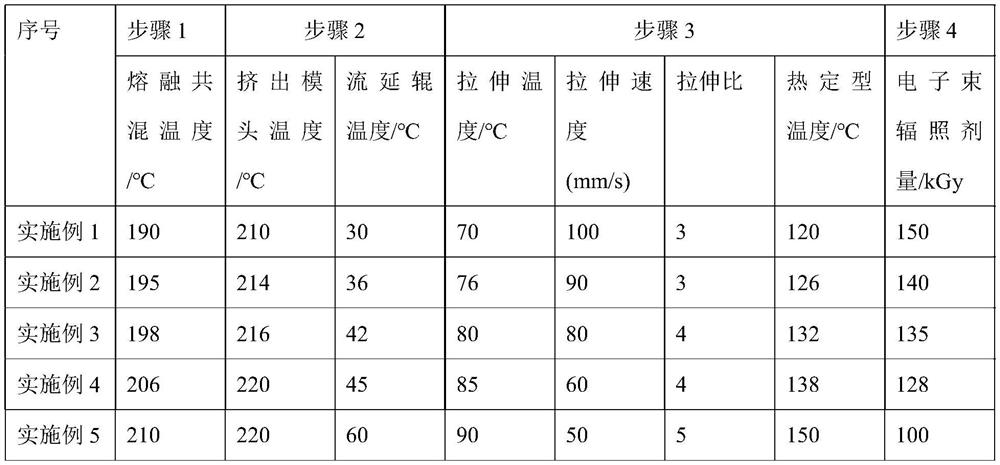

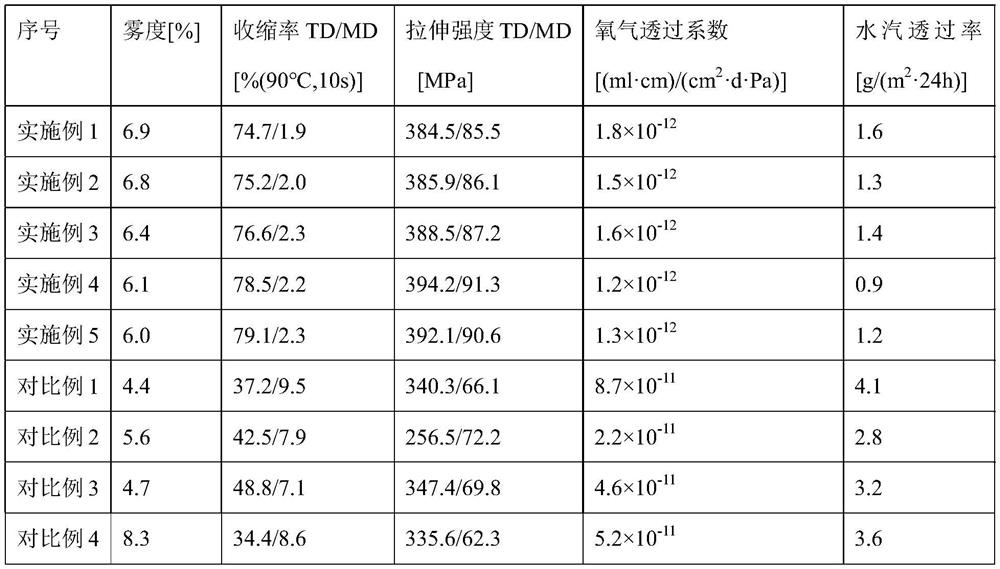

Embodiment 1

[0038] The degradable heat-shrinkable multilayer film of this embodiment is composed of a first outer layer, a second outer layer, and an inner layer disposed between the first outer layer and the second outer layer.

[0039] Wherein, the first outer layer and the second outer layer are prepared from the raw materials comprising the following parts by weight: 40 parts of PLA, 30 parts of PBAT, 30 parts of functional adjustment degradable masterbatch, 10 parts of compatibilizer, 6 parts of plasticizer, 1 part of slip agent, and 0.5 part of anti-aging agent;

[0040] The inner layer is prepared from the raw materials comprising the following components and their contents in parts by weight: 40 parts of PLA, 60 parts of PBAT, 10 parts of compatibilizer, 15 parts of soybean powder modified bamboo fiber, 2 parts of chain extender, plasticizer 5 parts, and 3 parts of slip.

[0041] In this embodiment, the used compatibilizer is glycidyl methacrylate grafted PLA, the melt index is abo...

Embodiment 2

[0047] The degradable heat-shrinkable multilayer film of this embodiment is composed of a first outer layer, a second outer layer, and an inner layer disposed between the first outer layer and the second outer layer.

[0048] Wherein, the first outer layer and the second outer layer are prepared from raw materials comprising the following parts by weight: 42 parts of PLA, 40 parts of PBAT, 18 parts of degradable master batches for function adjustment, 10 parts of compatibilizer, 8 parts of plasticizer, 1 part of slip agent, and 0.5 part of anti-aging agent;

[0049] The inner layer is prepared from the raw materials comprising the following components and their contents in parts by weight: 43 parts of PLA, 57 parts of PBAT, 8 parts of compatibilizer, 20 parts of soybean powder modified bamboo fiber, 2 parts of chain extender, plasticizer 6 parts, and 4 parts of slip.

[0050] In this embodiment, the used compatibilizer is glycidyl methacrylate grafted PLA, the melt index is a...

Embodiment 3

[0056] The degradable heat-shrinkable multilayer film of this embodiment is composed of a first outer layer, a second outer layer, and an inner layer disposed between the first outer layer and the second outer layer.

[0057] Wherein, the first outer layer and the second outer layer are prepared from the raw materials comprising the following parts by weight: 45 parts of PLA, 30 parts of PBAT, 25 parts of degradable master batches for function adjustment, 8 parts of compatibilizer, 10 parts of plasticizer, 2 parts of slip agent, and 0.7 part of anti-aging agent;

[0058] The inner layer is prepared from the raw materials comprising the following components and their contents in parts by weight: 46 parts of PLA, 54 parts of PBAT, 7 parts of compatibilizer, 23 parts of soybean powder modified bamboo fiber, 4 parts of chain extender, plasticizer 6 parts, and 5 parts of slip.

[0059] In this embodiment, the used compatibilizer is glycidyl methacrylate grafted PLA, the melt index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com