Bit body of diamond bit and manufacture method therefor

A technology of diamond bit and bit body, which is applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., achieves the effects of uniform stress distribution, reduced manufacturing cost, and enhanced comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

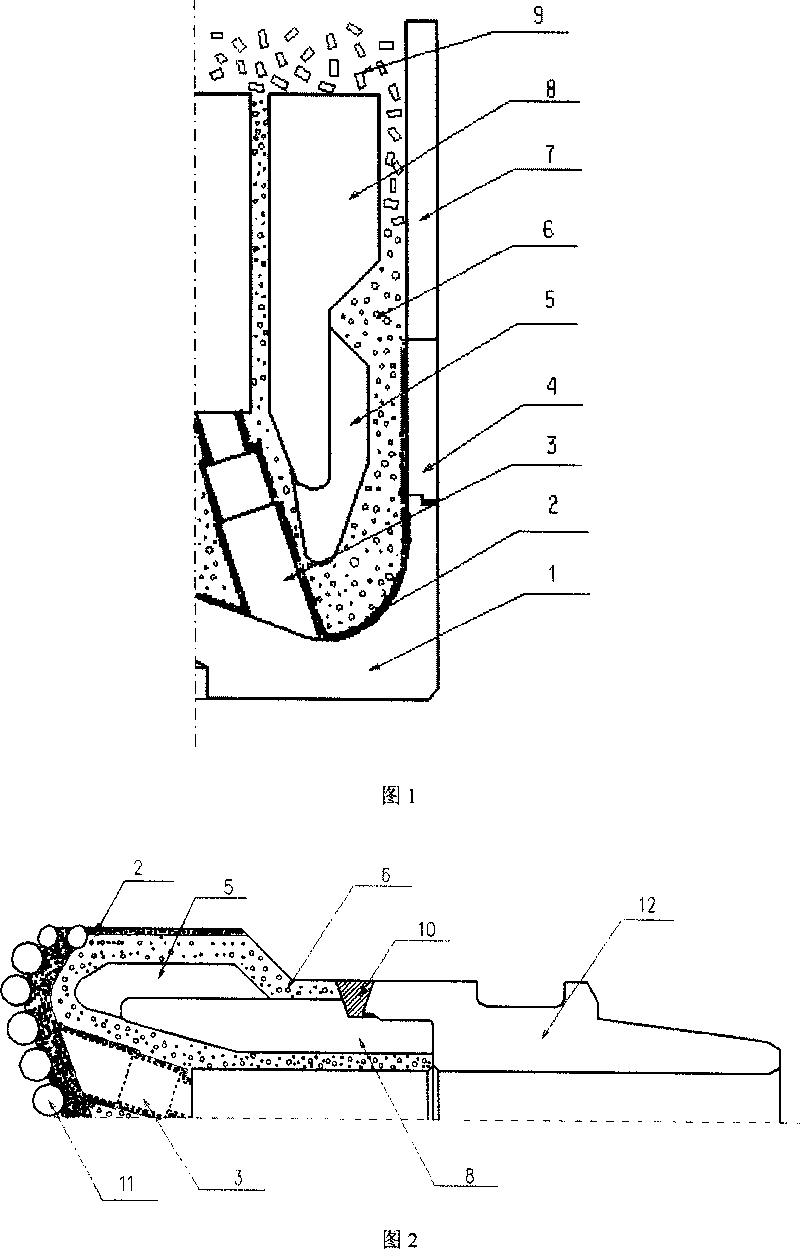

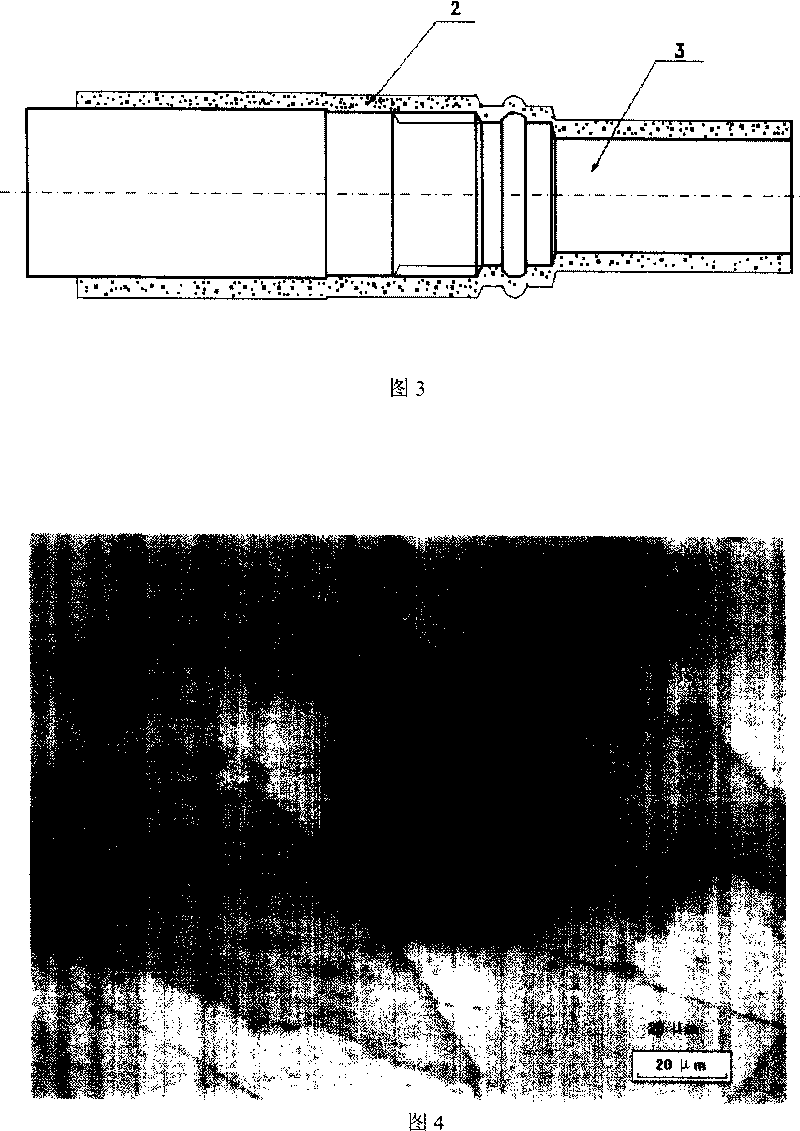

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The embodiment is shown in Figures 1 and 2. Firstly, cast tungsten carbide powder with a particle size between 0.037 mm and 0.149 mm is mixed with an adhesive to make a tungsten carbide powder colloid with certain adhesive properties. The content of the components mixed with tungsten carbide particles and adhesive is by weight. : Tungsten carbide particles 90%, the balance of adhesive. The adhesive is a fluid adhesive prepared by weight from 1 to 10% of glycerin, 5 to 15% of alkyl acrylate, and the remainder of diethylene glycol monobutyl ether, and then the tungsten carbide powder is uniformly bonded Apply on the assembled graphite concave cavity mold 1 and upper mold 4, and apply about 3 mm thick to form a sintered tungsten carbide sintered layer 2 to be sintered; similarly, apply a layer of 3 mm thick on the surface of the graphite nozzle hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com