Steel for X52 longitudinal welded pipe for thick-wall anti-HIC oil and gas pipeline and manufacturing method

A technology for oil and gas pipelines and straight seam welded pipes, applied in the field of low-carbon micro-alloy steel production, can solve the problems of not being suitable for the production of thick steel plates for HIC-resistant oil and gas pipelines, improve the pass rate of flaw detection, reduce the level of central porosity, and increase the pressure The effect of lower volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following embodiments are used to specifically illustrate the content of the present invention, and these embodiments are only general descriptions of the content of the present invention, and do not limit the content of the present invention.

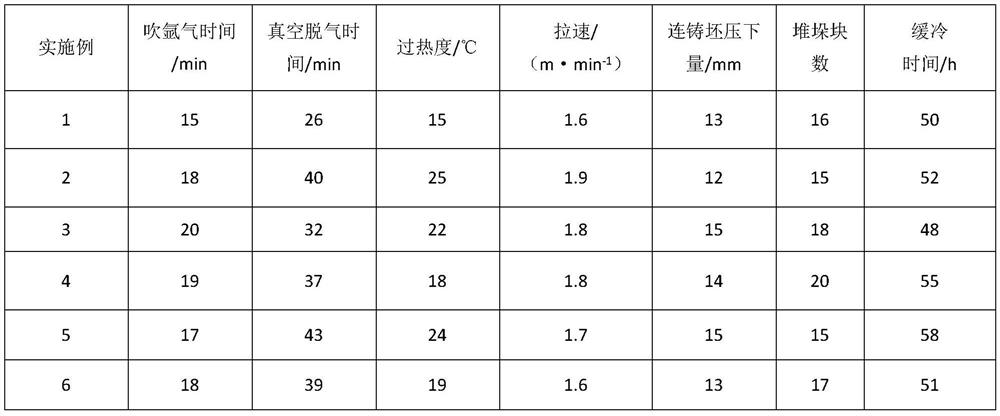

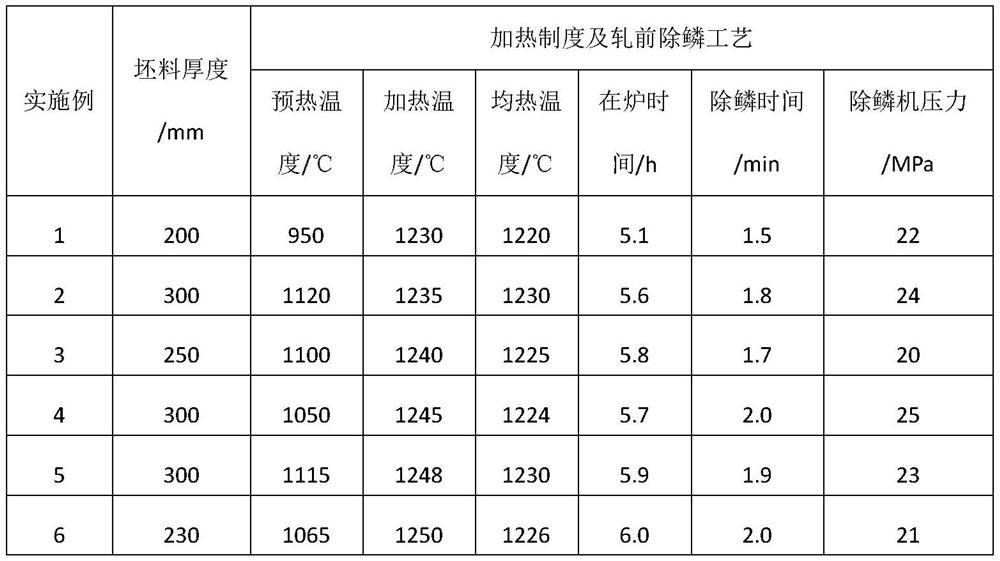

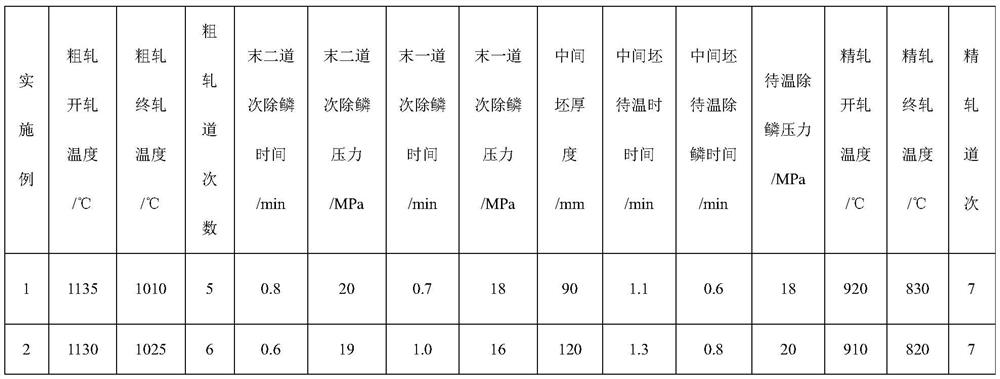

[0041] Wherein Table 1 is the chemical composition of the embodiment steel, Table 2 is the smelting process system of the embodiment steel, Table 3 is the heating system of the slab of the embodiment steel and the high-pressure water descaling process before the continuous casting slab rolling; Table 4 is the implementation The rolling parameters of the example steel; Table 5 is the reduction amount of each pass in different rolling stages of the example steel; Table 6 is the main process parameters of the controlled cooling of the example steel; Table 7 is the transverse mechanical properties of the example steel.

[0042] Table 1 Chemical composition (wt, %) of the embodiments of the present invention

[0043] Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com