Spherical hinge type track plate fine adjustment device

A track slab and adjustment device technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of difficult grouting work, inability to adjust the angle of the track slab, and high cost of the tray type, and achieves convenient and direct observation, simple and reliable structure, and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

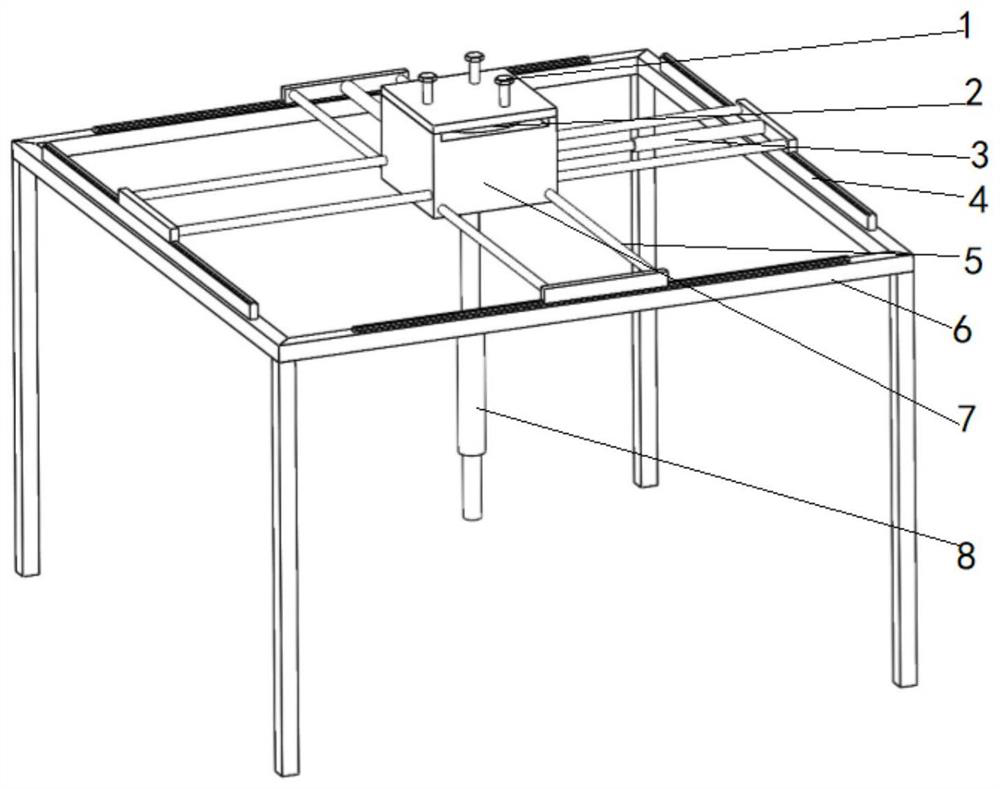

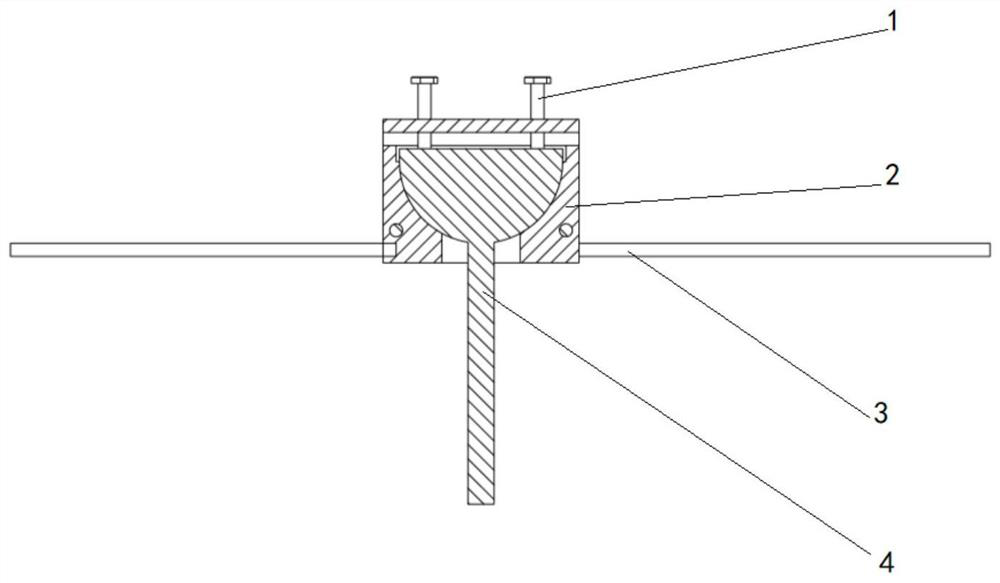

[0015] Specific implementation: as figure 1 As shown, a ball hinge type track plate fine adjustment device includes a frame 6, a sliding guide rail 4, a guide rod 5, a hydraulic cylinder 3 horizontally installed between the two guide rods, one end of the hydraulic cylinder is installed on the sliding guide rail, and the other end is installed on the sliding guide rail. It is installed on the outer box 7 of the spherical hinge to control the movement of the box, and the fixing bolt 1 of the spherical hinge is installed on the upper surface of the spherical hinge 2 .

[0016] In this way, the ball hinge type track plate fine adjustment device of this structure controls each hydraulic cylinder 3 respectively to adjust the position of the track plate during operation, and manually adjusts the ball hinge structure 2 to adjust the angle of the track plate. After the position adjustment of the track plate is completed, tighten the three ball hinge 1 fixing bolts on the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com