Dismounting device and method for heat insulation forming ring of solid rocket engine

A solid rocket and dismantling device technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of difficult disassembly, time-consuming and labor-intensive, damage to the shell and heat insulation layer, and achieve the effect of reducing labor intensity and improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

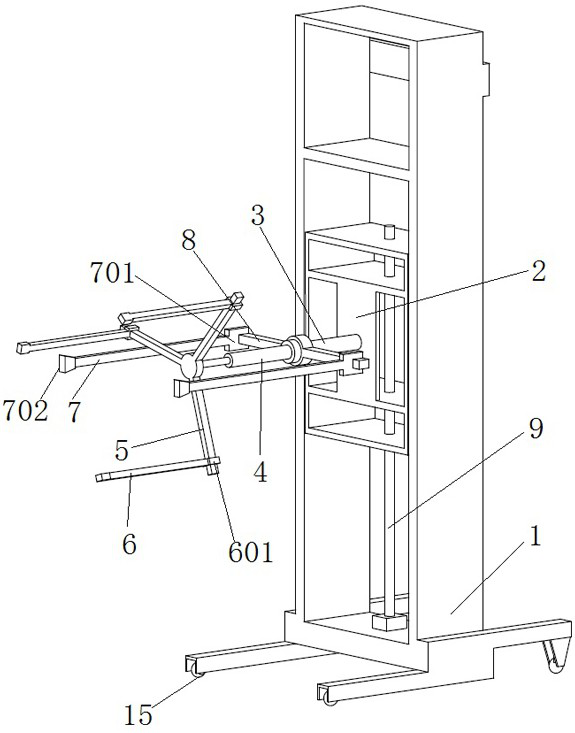

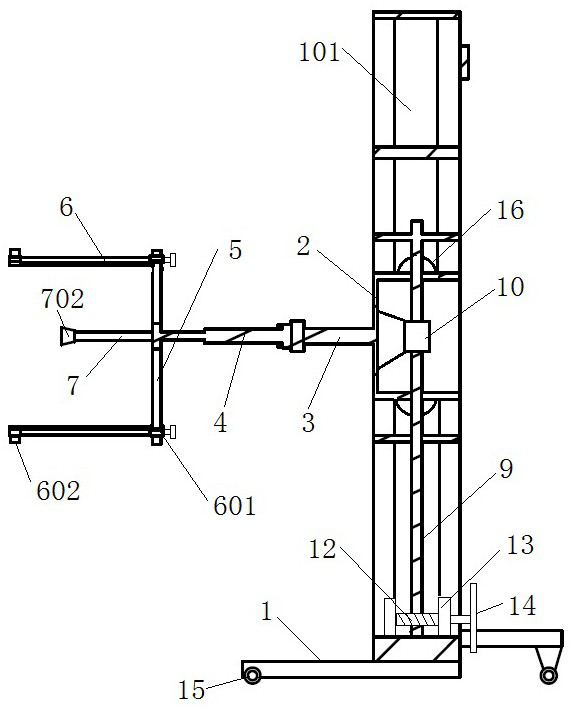

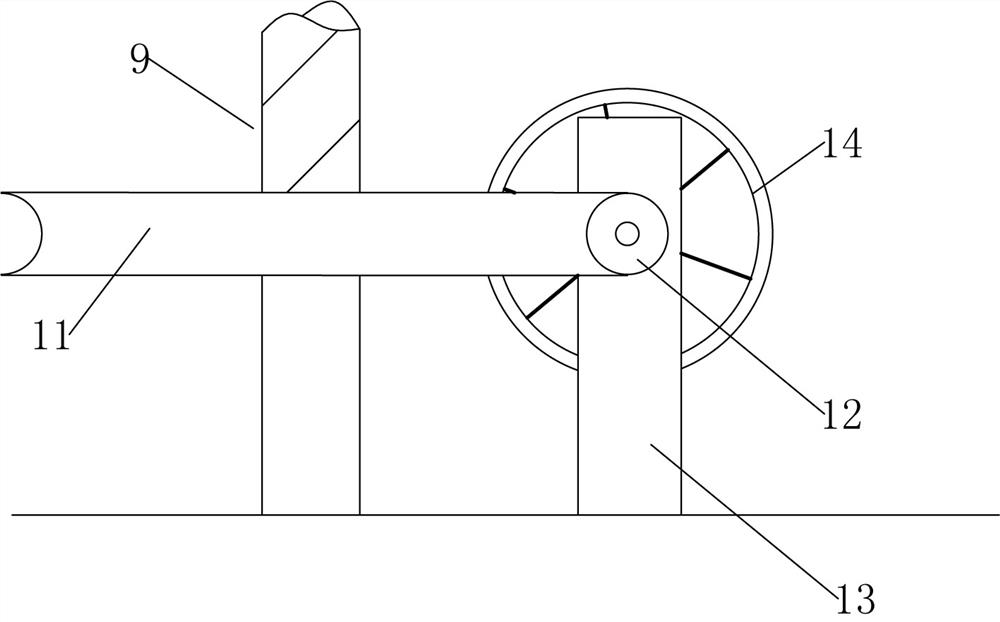

[0025] like Figure 1~2 As shown, a dismantling device for a solid rocket motor thermal insulation forming ring comprises a frame 1, a mounting seat 2 is arranged on the frame 1, a mounting frame 3 is arranged on the mounting seat 2, and a telescopic mechanism 4 is arranged on the mounting frame 3, In this embodiment, the telescopic mechanism 4 is a hydraulic cylinder, and the hydraulic cylinder can also be replaced by an air cylinder or the like. The telescopic end of the telescopic mechanism 4 is provided with a claw removal bracket 5, and the claw removal bracket 5 is provided with a claw removal bracket 6. In this embodiment, the number of the removal claws 6 is three, and the tail end of the removal claw 6 is provided with a claw removal bracket. 5. The sliding ring 601 is matched with the sliding ring 601. The sliding ring 601 moves along the claw removal bracket 5, and the position of the claw removal 6 can be adjusted. From 602 , a plurality of jacking rods 7 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com