Vulcanization equipment for rubber tire processing and use method thereof

A technology for rubber tires and equipment, applied in the field of rubber tire processing equipment, can solve the problems of time-consuming and laborious removal, reduce work efficiency, and discomfort for staff, and achieve the effects of reducing odor emission, improving processing quality, and ensuring production quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

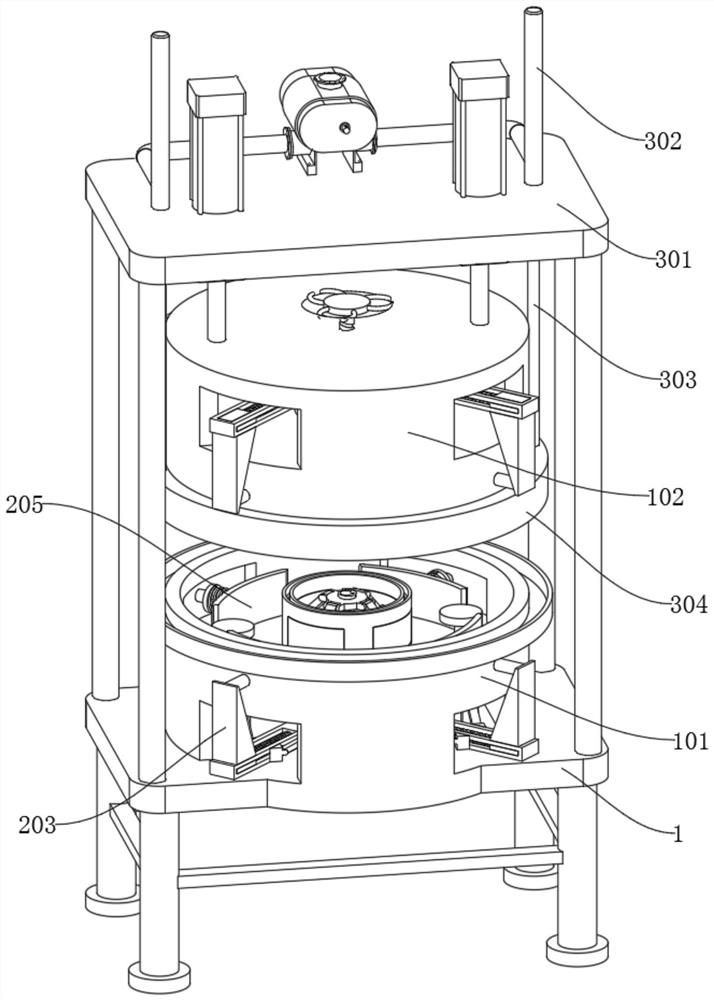

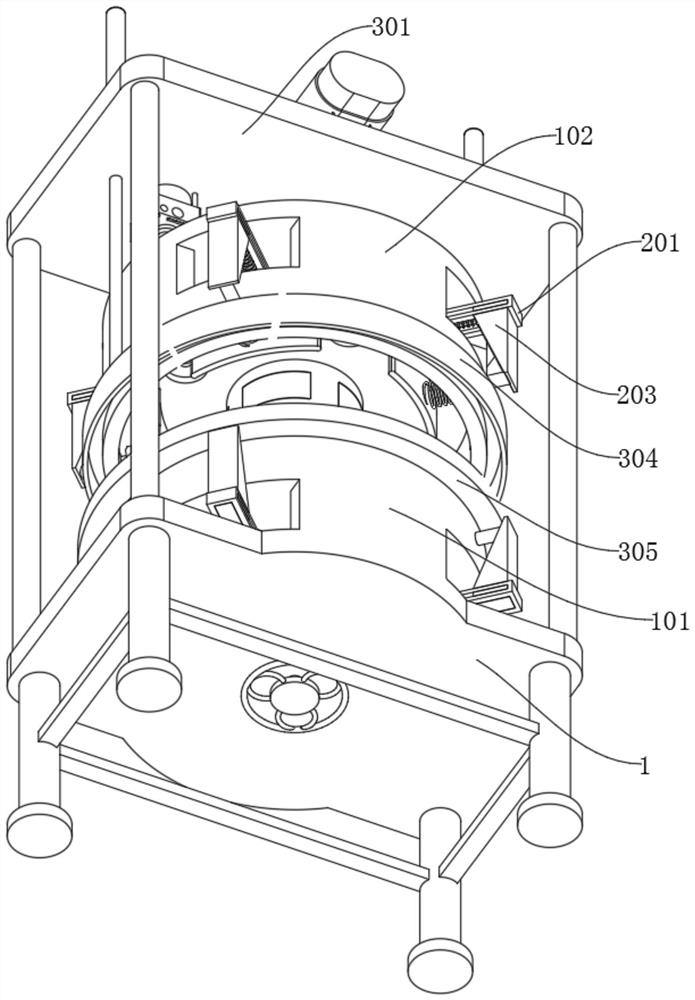

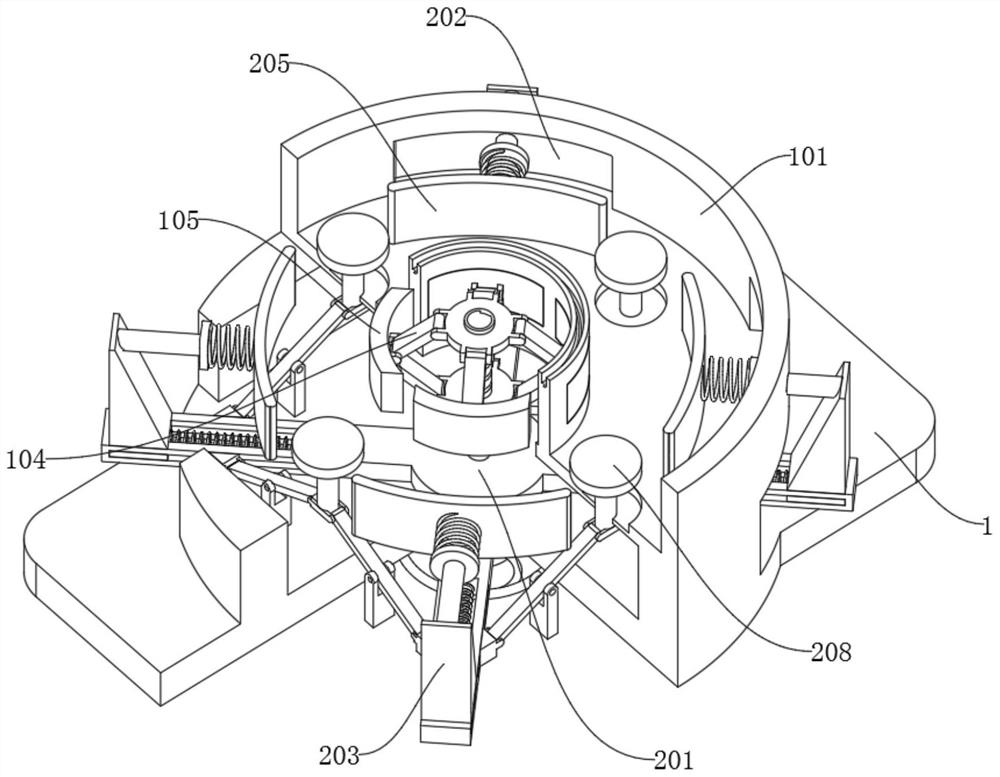

[0046] Example: please refer to Figure 1 to Figure 8 :

[0047] The present invention proposes a vulcanization equipment for processing rubber tires and a method of using the same, comprising: a main body 1, the top of the main body 1 is provided with legs, and the top of the main body 1 is provided with a lower plate 101, and the upper part of the lower plate 101 An upper plate 102 is installed, a threaded rod is installed in the middle of the lower plate 101 and the upper plate 102, and a fixing mechanism 2 is installed on the top of the main body 1; the fixing mechanism 2, the carrier plate 201 in the fixing mechanism 2 is respectively installed on the lower plate 101 and The outer side of the threaded rod in the middle position of the upper plate 102 ; the collecting assembly 3 , the collecting assembly 3 is installed above the main body 1 , and the collecting assembly 3 is located above the fixing mechanism 2 .

[0048] Furthermore, according to embodiments of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com