Hidden electronic rearview mirror bracket mounting structure for vehicle

A technology of electronic rearview mirror and installation structure, which is applied to vehicle parts, signal devices, transportation and packaging, etc., can solve the problems that the electronic rearview mirror cannot be hidden and the vehicle electronic rearview mirror cannot be moved, etc., and achieves enhanced practicality. Sexual, easy-to-observe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

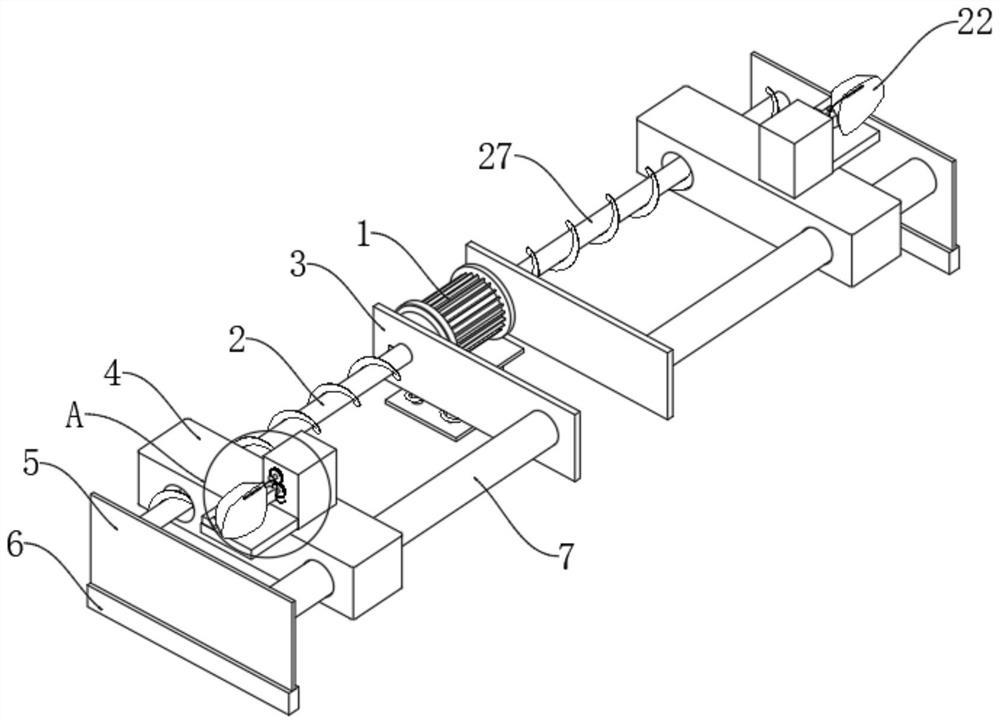

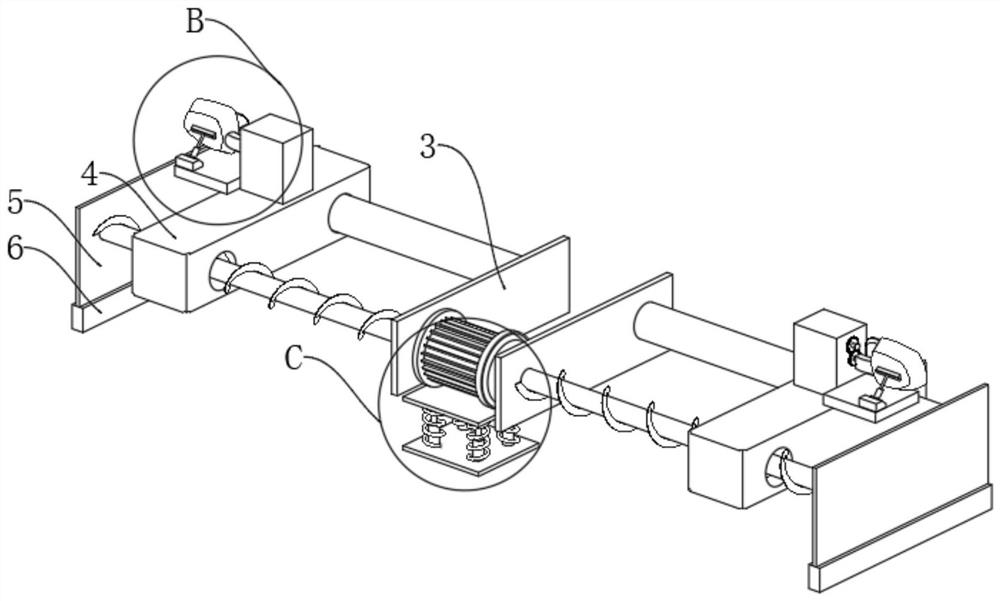

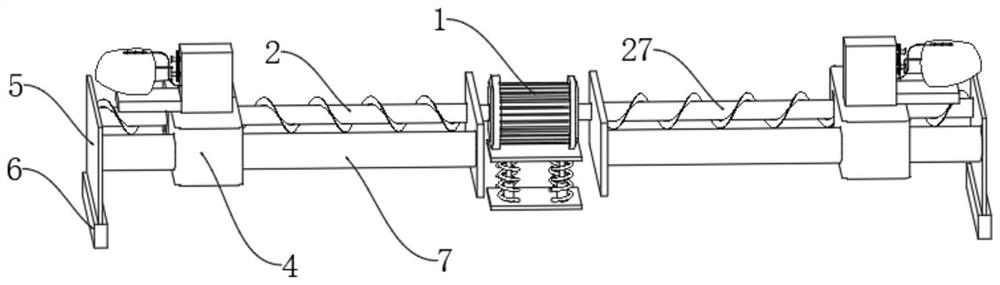

[0031] The present invention provides such as Figure 1-8 The shown mounting structure of a concealable electronic rearview mirror bracket for a vehicle includes a biaxial drive motor 1, a sliding block 4, a connecting rod 7, a first connecting shaft 9, a second gear 13, a mounting plate 18, an electric telescopic Rod 20, anti-skid rubber plate 23, shock-absorbing spring 24 and anti-skid square plate 26, one end of the biaxial drive motor 1 is connected with a first lead screw 2, the other end of the two axis drive motor 1 is connected with a second lead screw 27, the first lead screw The rod 2 and the connecting rod 7 are parallel to each other, the sliding block 4 is installed on the outer walls of the first screw rod 2 and the second screw rod 27, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com