Integral transportation support for rear half section of gas compressor

An integral transport, compressor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

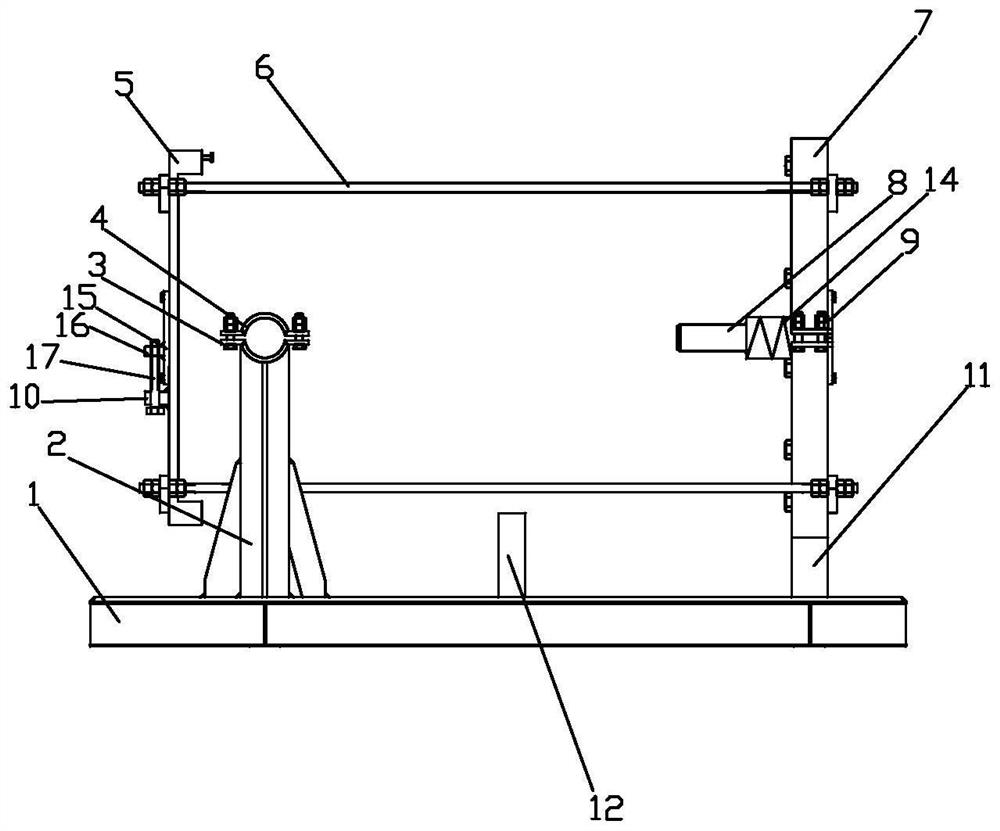

[0022] Embodiment 1: Combining figure 1 and figure 2 Describing this embodiment, an integral transport bracket for the second half of the compressor described in this embodiment includes a base 1 , a strut 2 , a stopper 3 , a gland 4 , a No. 1 baffle 5 , a pull rod 6 , and a No. 2 baffle 7 , extension shaft 8, No. 1 positioning plate 9, adjusting block 10, No. 1 arc baffle 11, No. 2 arc baffle 12, spring 14, No. 2 positioning plate 15, nut 16 and screw 17;

[0023] One end and two sides of the upper surface of the base 1 are respectively provided with a pillar 2, and the top of each pillar 2 is processed with an arc-shaped through hole. A gland 4 is provided, and one end of the gland 4 is fixedly connected with the stopper 3 on the top side of the pillar 2 through bolts, and the other end of the gland 4 is fixedly connected with the stopper 3 on the other side of the top of the pillar 2 through bolts The middle of the upper surface of the base 1 is provided with a No. 2 arc...

specific Embodiment approach 2

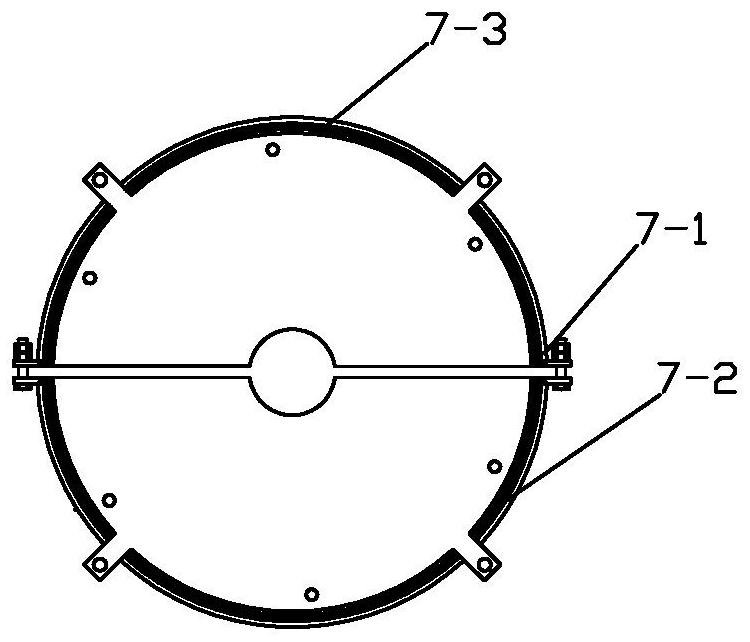

[0025] Specific implementation mode 2: Combining image 3This embodiment is described. This embodiment is a further limitation of the transport bracket described in Embodiment 1. In the overall transport bracket for the second half of the compressor described in this embodiment, the No. 2 baffle 7 includes: The upper semicircular baffle 7-3, the lower semicircular baffle 7-2 and the shock-absorbing rubber plate 7-1;

[0026] A connecting baffle is respectively provided on both sides of the upper surface of the upper semicircular baffle 7-3 and the lower semicircular baffle 7-2, and the upper semicircular baffle 7-3 is connected to the lower semicircular baffle through bolts. The plate 7-2 is fixedly connected, and a shock-absorbing rubber plate 7-1 is respectively provided on the end surfaces of the upper semicircular baffle 7-3 and the lower semicircular baffle 7-2;

[0027] In this specific embodiment, the upper semicircular baffle 7-3 and the end surface of the lower semic...

specific Embodiment approach 3

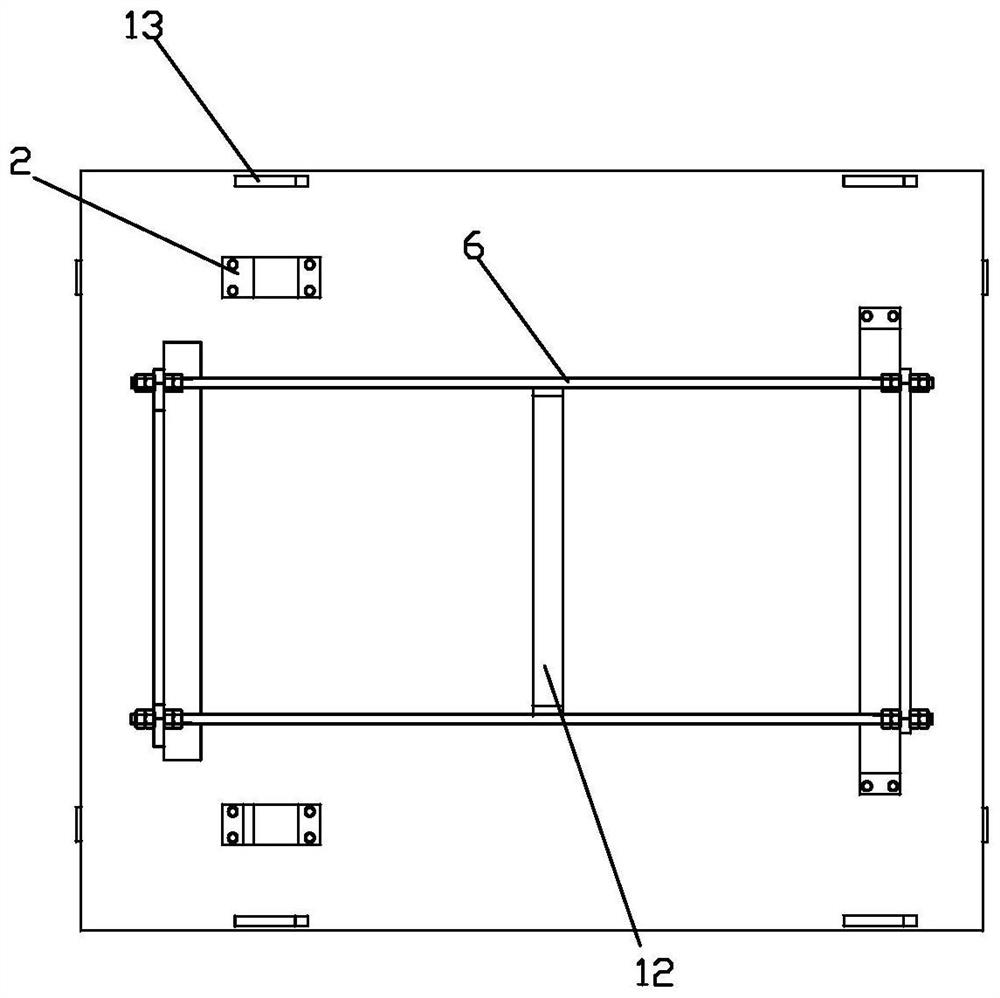

[0028] Specific implementation three: combination figure 2 This embodiment is described. This embodiment is a further limitation of the transport bracket described in the first embodiment. In the overall transport bracket for the second half of the compressor described in this embodiment, the four corners of the upper surface of the base 1 A lifting lug 13 is respectively provided;

[0029] In this specific embodiment, a lifting lug 13 is respectively provided at the four corners of the upper surface of the base 1 to facilitate the lifting of the transport bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com