Steel cord take-up device and take-up method

A wire take-up device and steel cord technology, which is applied in the directions of transportation and packaging, thin material handling, and delivery of filamentous materials, etc., can solve the problems of steel cord take-up efficiency, product quality and production equipment cost, The take-up device takes up a lot of space and other problems, so as to achieve the effect of taking up a small space, improving the efficiency of take-up and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

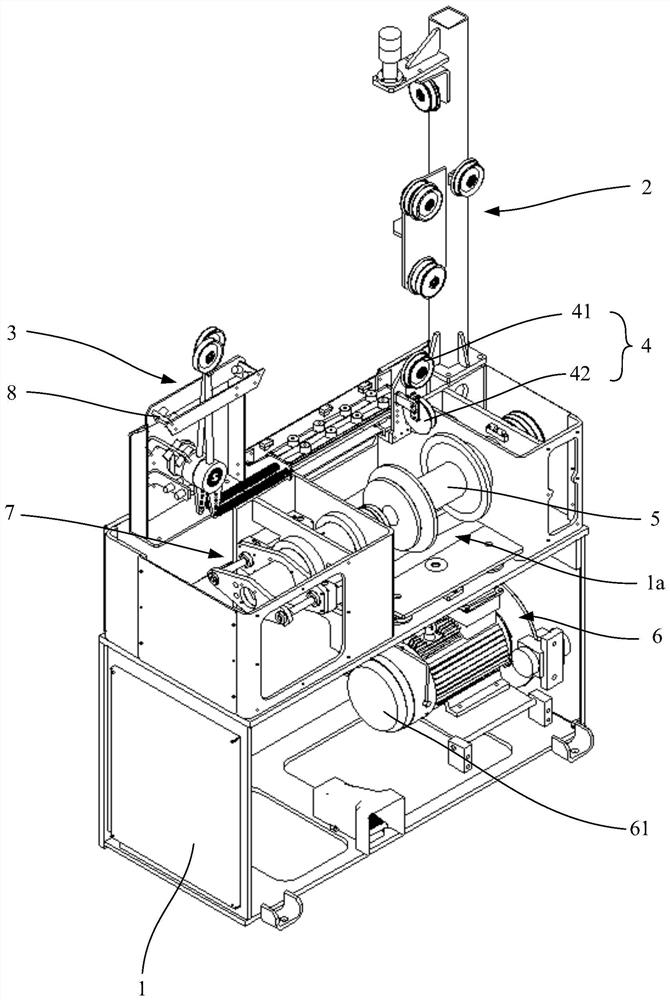

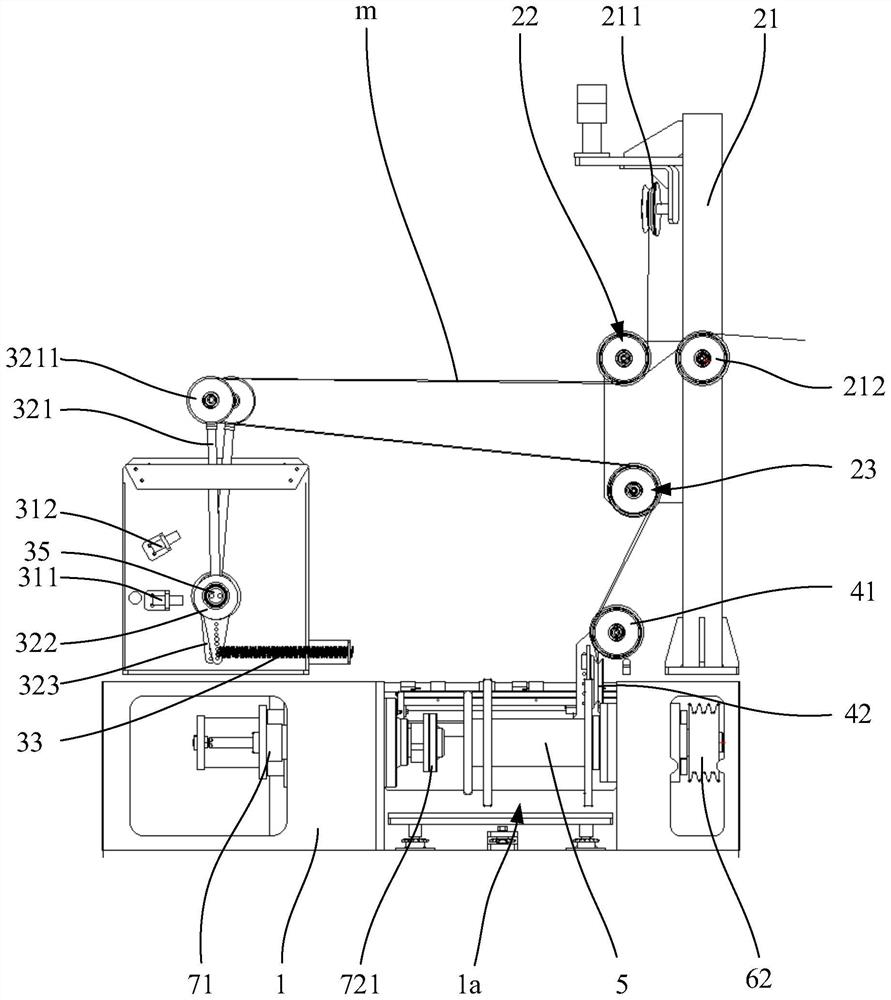

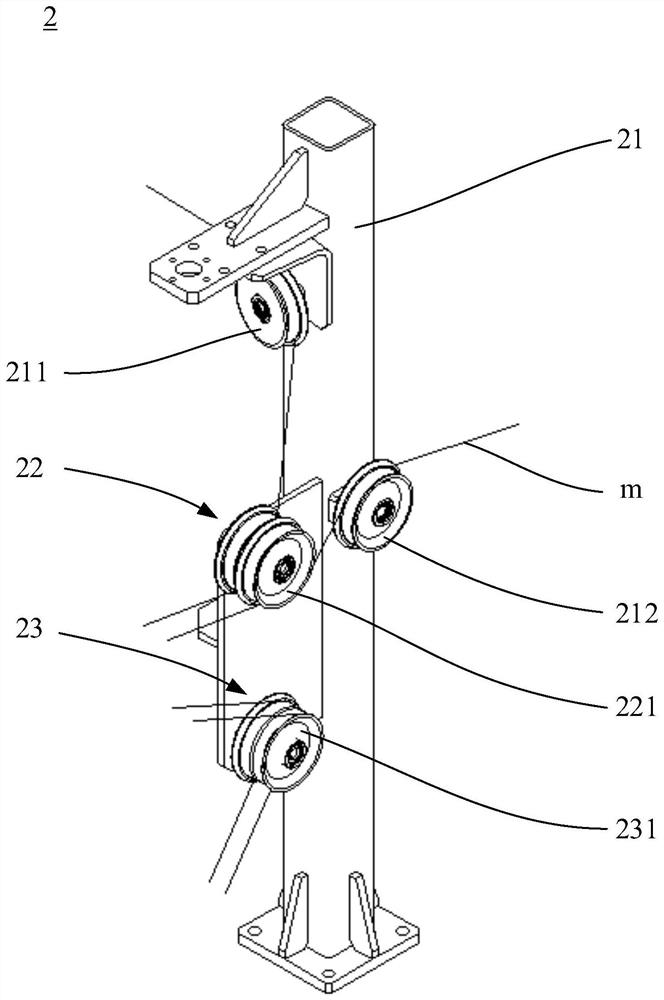

[0036] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0037] In the related art, after the finished steel cord monofilament is drawn, it is usually wound on an I-shaped wheel by means of monofilament take-up for take-up. That is, when the I-shaped wheel rotates to realize the winding and take-up of the steel cord monofilament, only one steel cord monofilament is being wound at the same time.

[0038] By adopting the single-wire winding method, it takes a long time to complete the winding of the steel cord on the entire roll of the I-shaped wheel, and the efficiency is low. However, if multiple steel cords are to be used for take-up and winding on the same I-shaped wheel at the same time, high requirements are required for the winding sequence of steel cords and the balance of tension during wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com