Preparation method and device of liquid polycarbosilane ceramic precursor

A technology of ceramic precursors and polycarbosilane, which is applied in pressure vessels used in chemical processes, pressure vessels/vacuum vessels, etc., can solve the problems affecting the mechanical properties of composite materials, low impregnation efficiency, low density, etc., and achieve excellent flow High impregnation efficiency, high impregnation efficiency, and less air bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

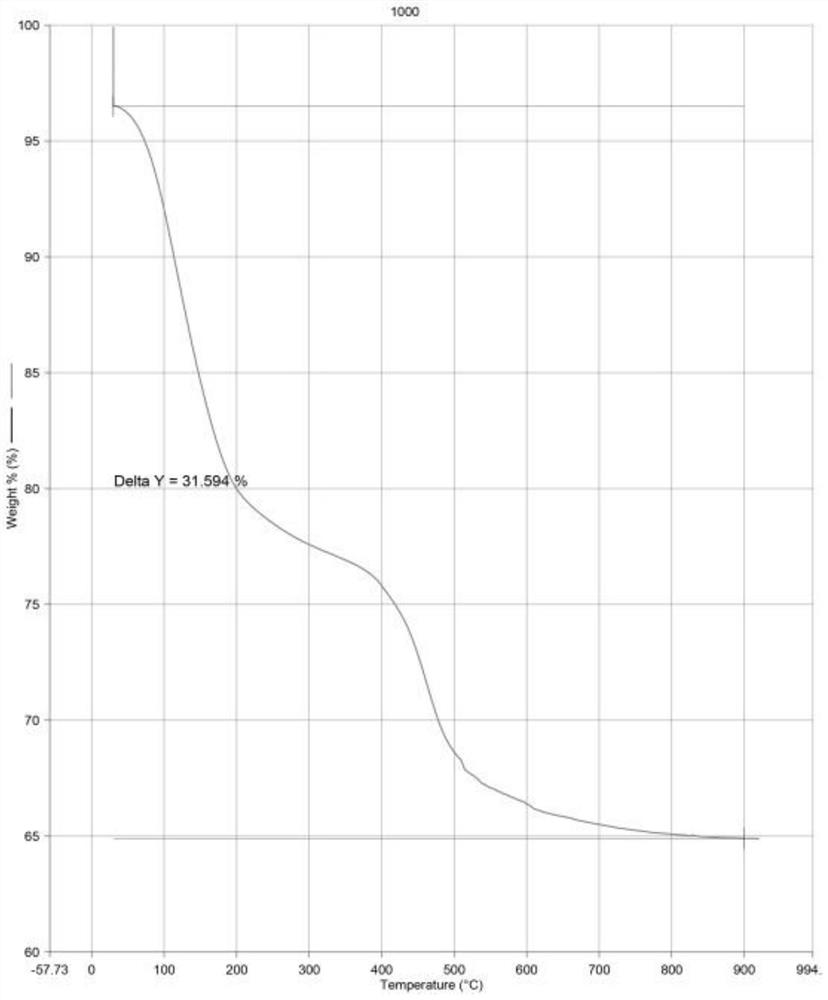

Examples

preparation example Construction

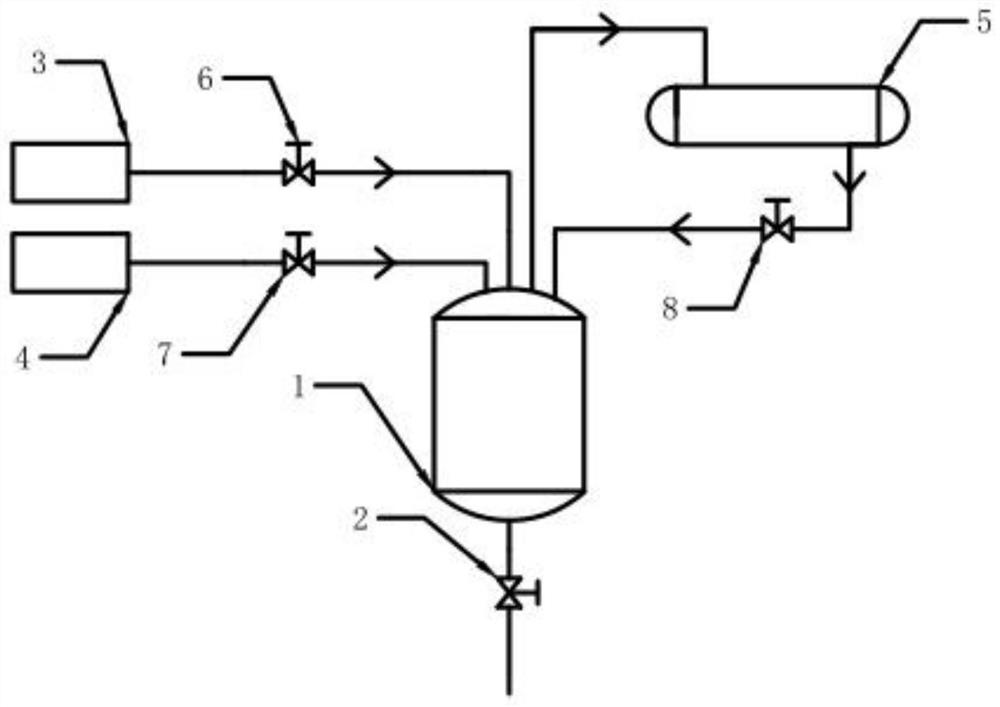

[0032] The preparation method of a liquid polycarbosilane ceramic precursor provided by the invention comprises the following steps:

[0033] (1) heating the reaction kettle 1 to 100 ℃~110 ℃, vacuuming to -0.08MPa~-0.095MPa, keeping the temperature for 1h~3h, drying the reaction kettle 1 to remove moisture; then open the nitrogen valve 7 to put the nitrogen in the nitrogen tank 4 The nitrogen is passed into the reaction kettle 1 to replace the air in the reaction kettle 1, after repeated operations three times, the nitrogen is introduced and then cooled to 40 ° C ~ 60 ° C, and the reaction kettle 1 is kept in a slightly positive pressure state.

[0034] (2) successively add tetrahydrofuran, metal magnesium and 1,1,3,3-tetrachloro-1,3-disilazane into the reactor 1, keep the temperature of the reactor at 40 ℃~60 ℃, open the condenser and The stirring device of the reaction kettle of the reaction kettle, while stirring, add the first batch of chlorosilanes, control the temperatur...

Embodiment 1

[0040]The preparation method of a liquid polycarbosilane ceramic precursor provided by the invention comprises the following steps:

[0041] (1) reaction kettle 1 is heated to 100° C., evacuated to -0.08MPaMPa, kept for 1 h, and reaction kettle 1 is dried to remove moisture; then open nitrogen valve 7 to pass nitrogen in nitrogen tank 4 into reaction kettle 1 The air in the reaction kettle 1 was replaced, and after the operation was repeated three times, nitrogen was introduced, and then the temperature was lowered to 40° C., and the reaction kettle 1 was kept in a slightly positive pressure state.

[0042] (2) successively add tetrahydrofuran, metallic magnesium and 1,1,3,3-tetrachloro-1,3-disilazane in the reactor 1, keep the reactor temperature at 40 ° C, open the condenser and the reactor The stirring device of the reaction kettle, while stirring, add the first batch of chlorosilanes, control the temperature of the reaction kettle 1 to be lower than 60 ° C, wait for the re...

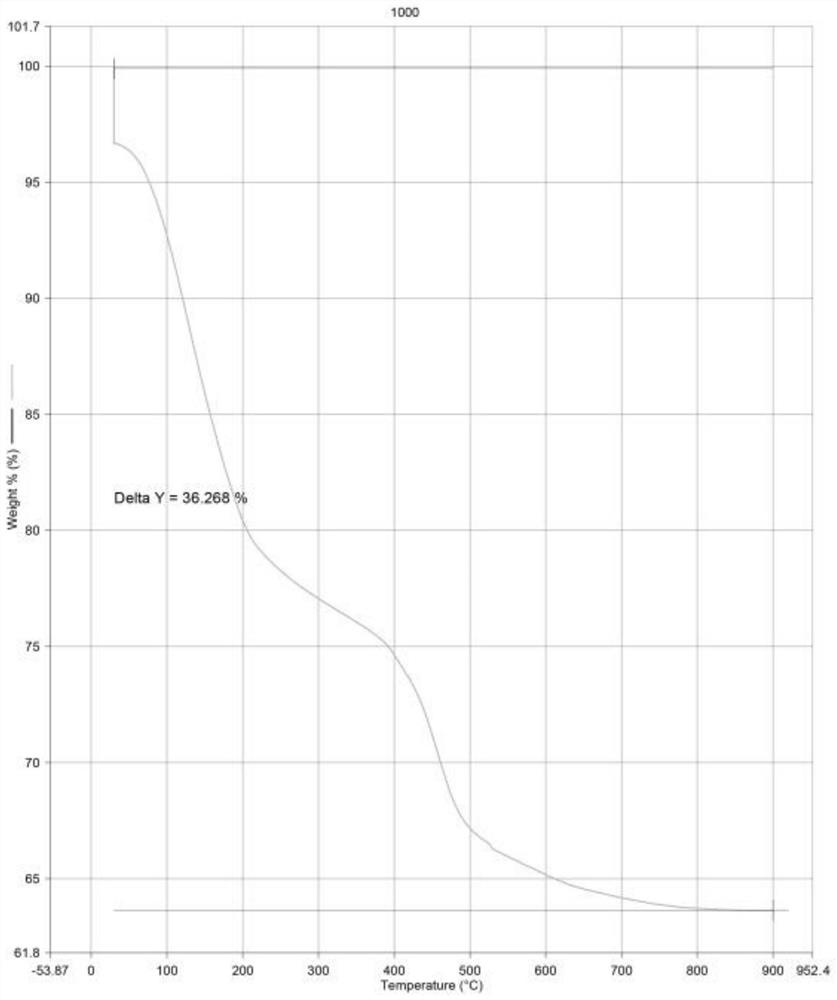

Embodiment 2

[0046] The preparation method of a liquid polycarbosilane ceramic precursor provided by the invention comprises the following steps:

[0047] (1) heating the reactor 1 to 105°C, vacuuming to -0.095MPa, keeping the temperature for 2h, drying the reactor 1 to remove moisture; then open the nitrogen valve 7 to pass the nitrogen in the nitrogen tank 4 into the reactor 1 The air in the reaction kettle 1 was replaced, and after repeated operations three times, nitrogen was introduced, and then the temperature was lowered to 40°C to 60°C, and the reaction kettle 1 was kept in a slightly positive pressure state.

[0048] (2) in reactor 1, add tetrahydrofuran, metallic magnesium and 1,1,3,3-tetrachloro-1,3-disilazane successively, keep reactor temperature to be 50 ℃, open condenser and reactor The stirring device of the reaction kettle, while stirring, add the first batch of chlorosilanes, control the temperature of the reaction kettle 1 to be lower than 60 ° C, wait for the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap