Electrode adjusting device and method for aluminum alloy solidification electric pulse treatment

An electrode adjustment and aluminum alloy technology, which is applied in the field of aluminum alloy casting, can solve problems such as poor contact between electrodes and aluminum alloy liquid, inaccurate adjustment, inconvenient disassembly, etc., to overcome inaccurate electrode adjustment, improve work efficiency, and solve problems The effect of inconvenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict, and the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

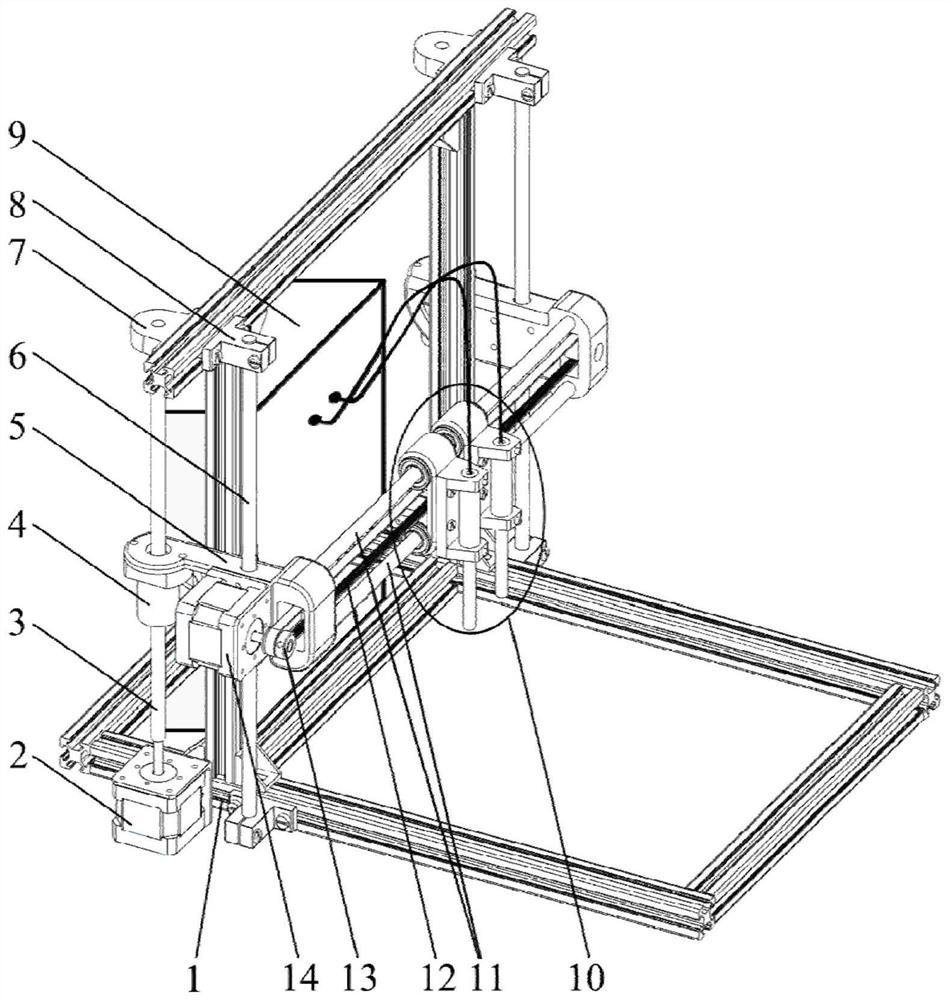

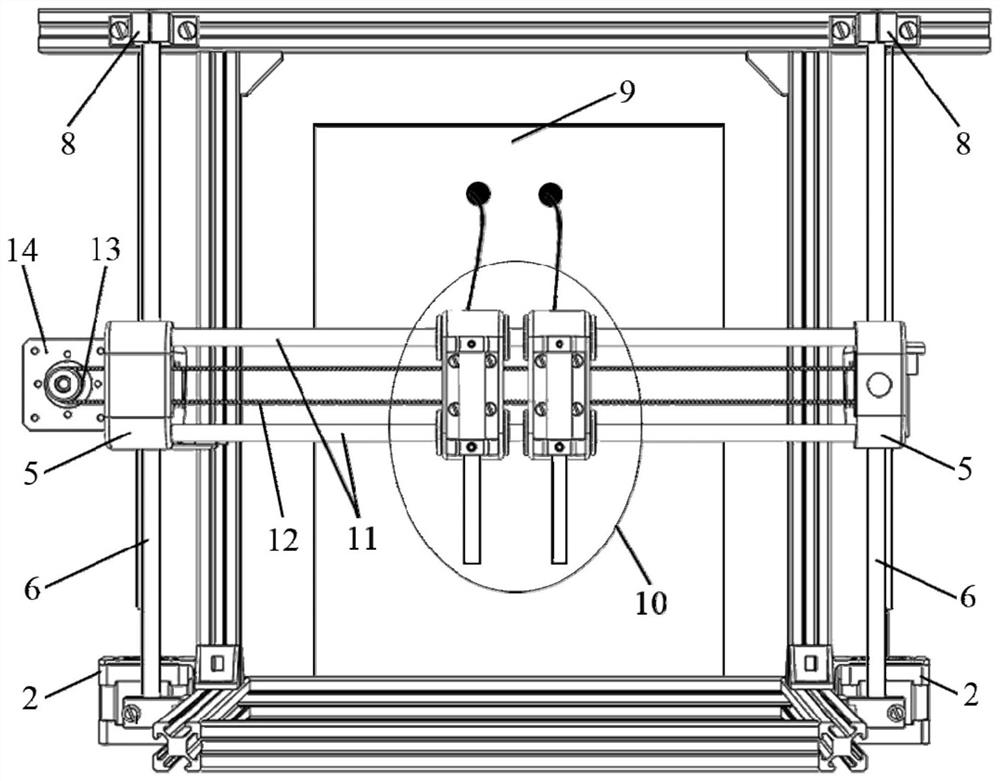

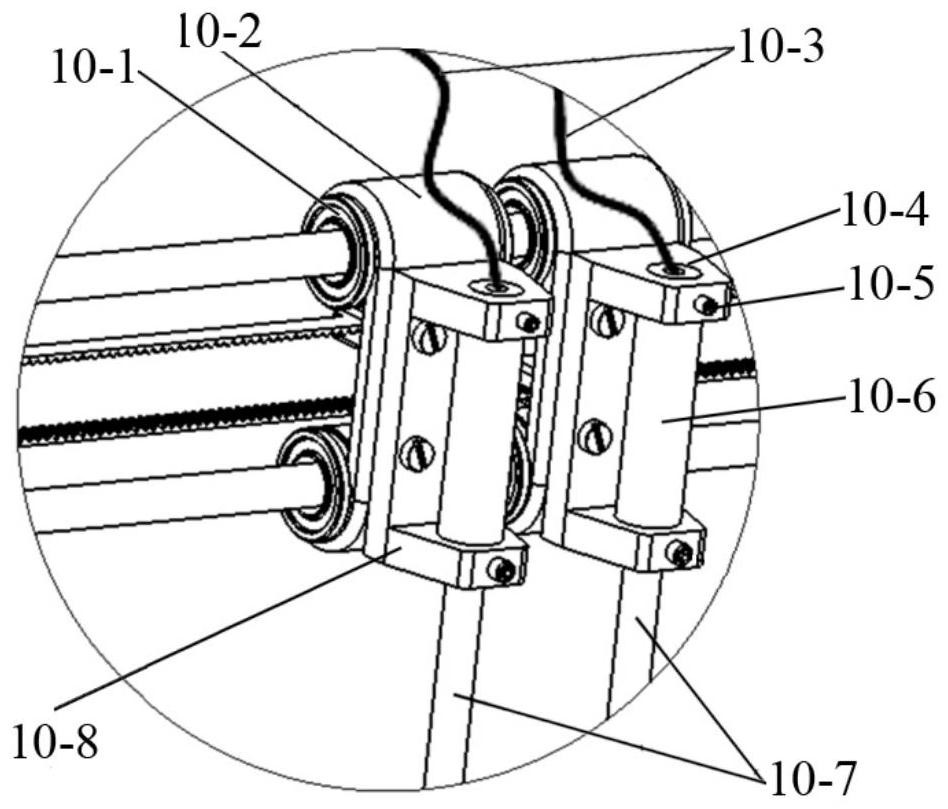

[0033] like Figure 1-Figure 4 As shown in the figure, an electrode adjustment device for electric pulse treatment of aluminum alloy solidification includes a frame 1, a Z-direction motor 2, a lead screw 3, a T-shaped nut 4, a pulse power supply 9, an electrode insertion mechanism 10, a belt 12, and a synchronous pulley. 13 and the X-direction motor 14, the pulse power supply 9 is arranged at the rear of the frame 1, a Z-direction motor 2 is arranged on the left and right sides of the frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com