Dredging device for water conservancy project

A technology for dredging devices and water conservancy projects, applied in separation methods, filtration separation, mechanically driven excavators/dredgers, etc., can solve the problems of complex structure, low dredging efficiency, and high cost of dredging devices, and improve the efficiency of dredging. Silt range, simple structure, and the effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

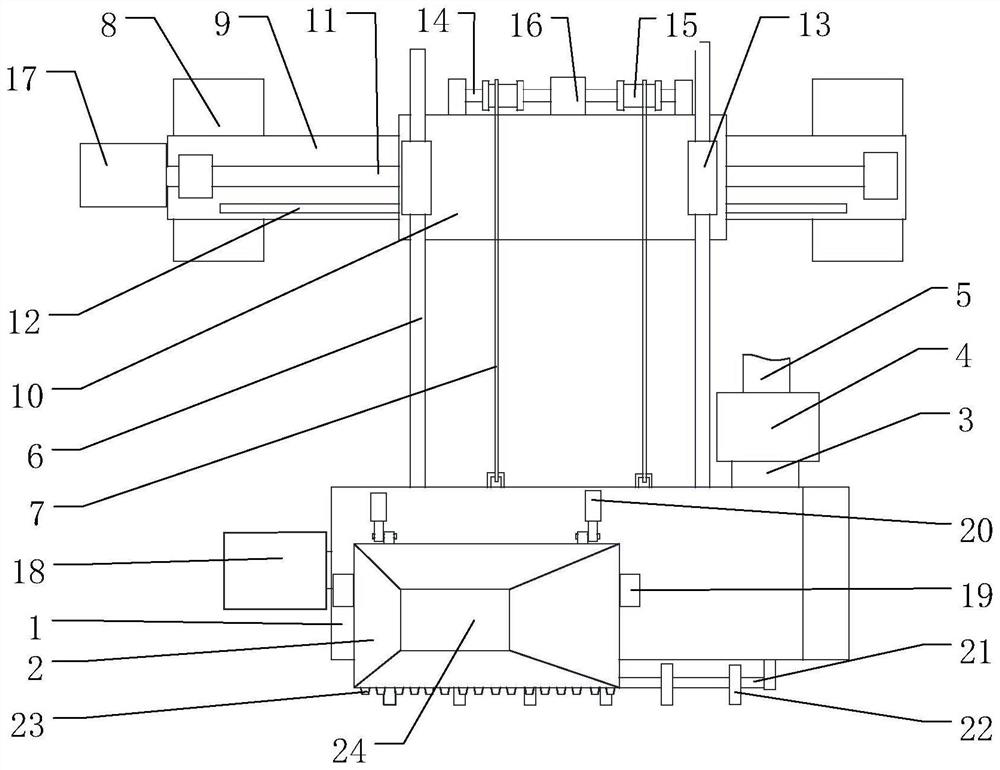

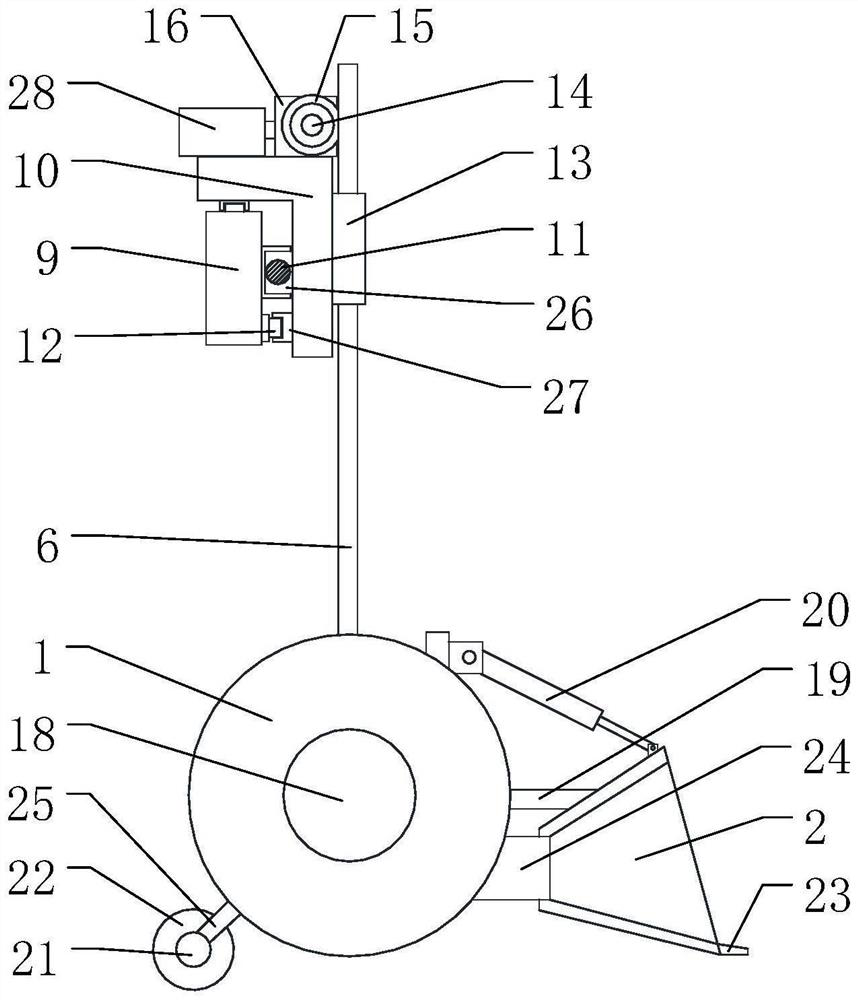

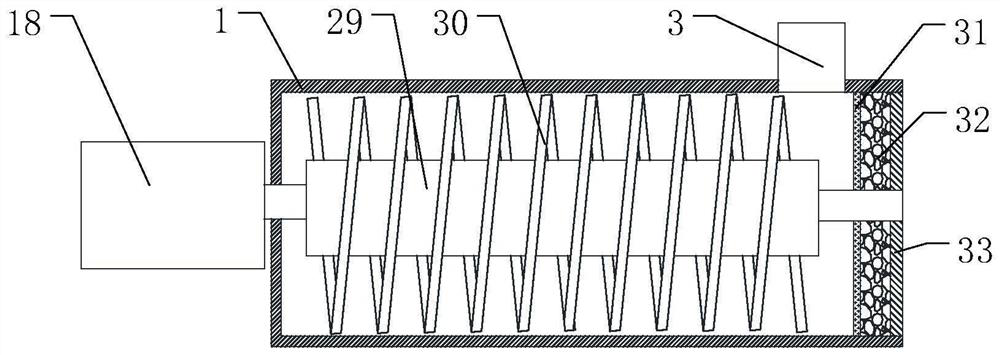

[0029] A dredging device for water conservancy projects, comprising a conveying cylinder 1, and the conveying cylinder 1 is made of wear-resistant steel. A bucket 2 is arranged at the silt inlet at one end of the conveying cylinder 1, and the bucket 2 is a funnel-shaped structure with a large open end. The bucket 2 is connected to the sludge inlet through a connecting hose 24 . The bottom end of the open end of the bucket 2 is provided with a plurality of teeth 23, the teeth 23 are trapezoidal structures, and the teeth 23 are convenient for inserting the bucket 2 into the mud and shoveling the mud into the bucket 2.

[0030] The bucket 2 is connected with the conveying drum 1 through the connecting plate 19 , the connecting plate 19 is fixed on the conveying drum 1 , and the bucket 2 is hinged with the connecting plate 19 . The conveying drum 1 is provided with an angle adjusting structure for adjusting the angle of the bucket 2 . The angle adjustment structure includes a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com