Tunnel secondary lining longitudinal water-stop belt mounting device and mounting method thereof

A technology for vertical water sealing and installation of devices, which is applied in tunnel lining, tunnel, shaft equipment, etc., can solve problems such as reducing service life and affecting tunnel performance, and achieve the effects of ensuring integrity, wide applicability, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

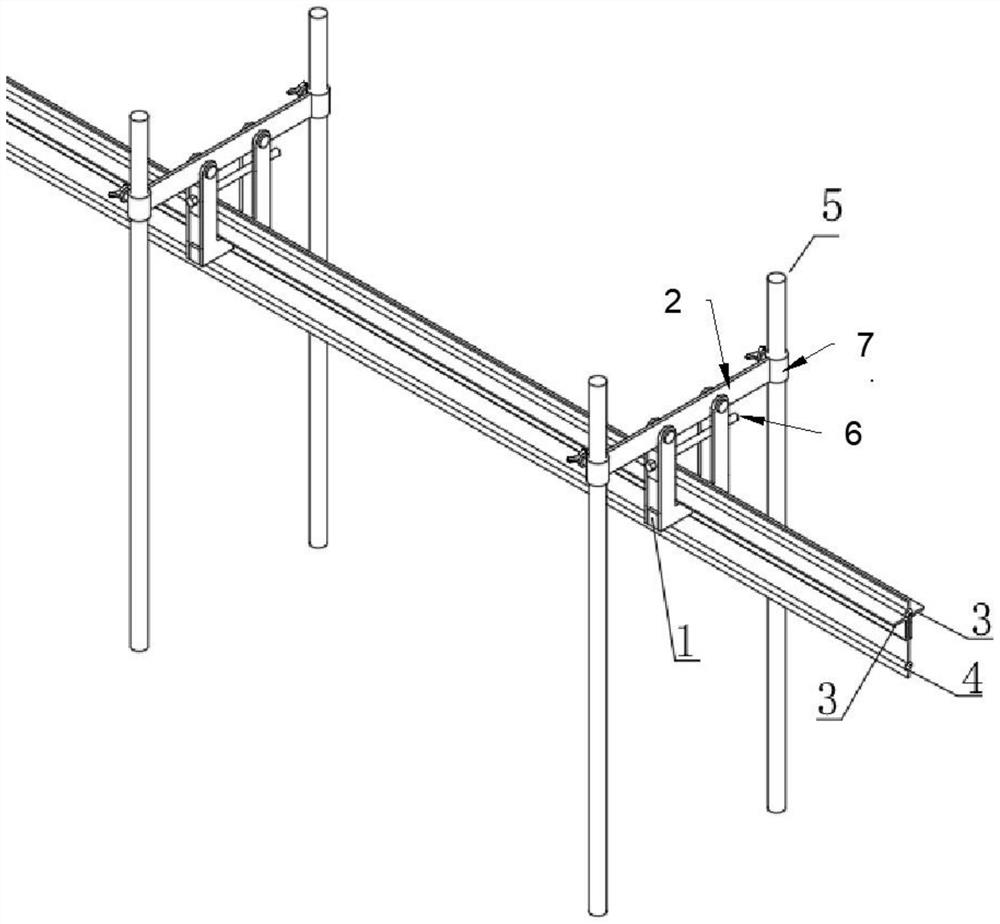

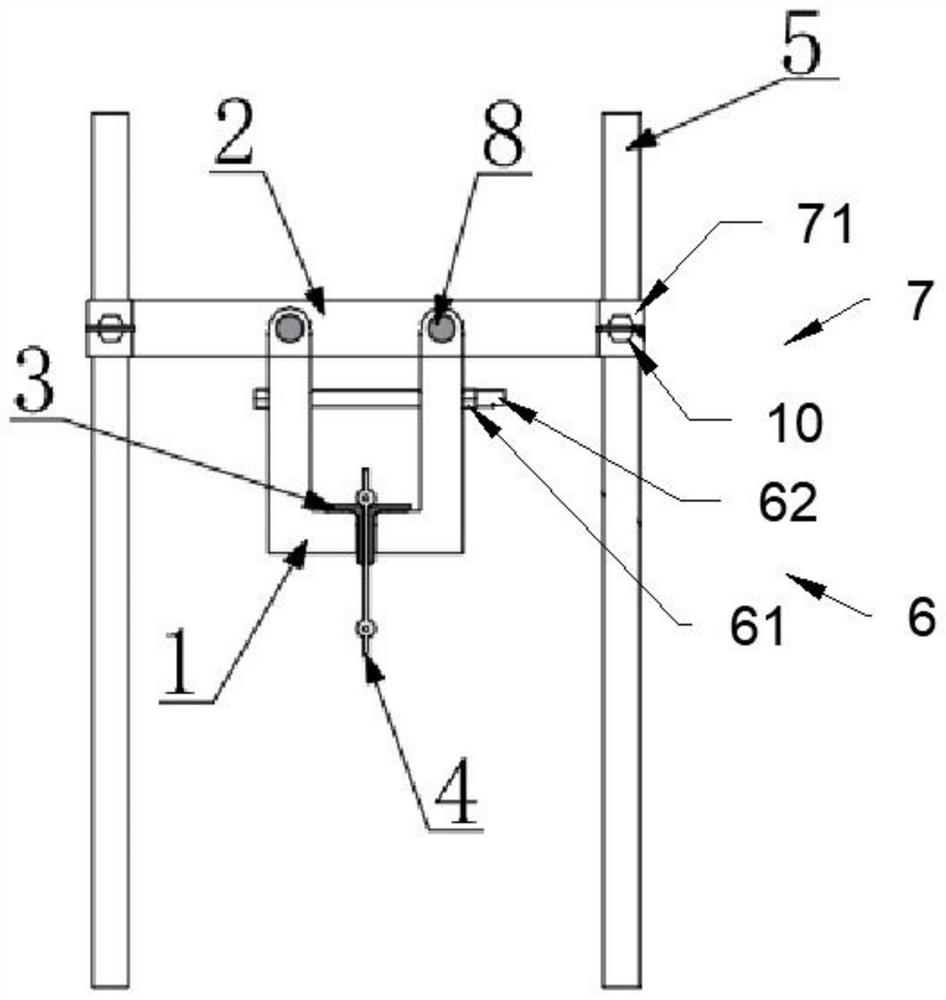

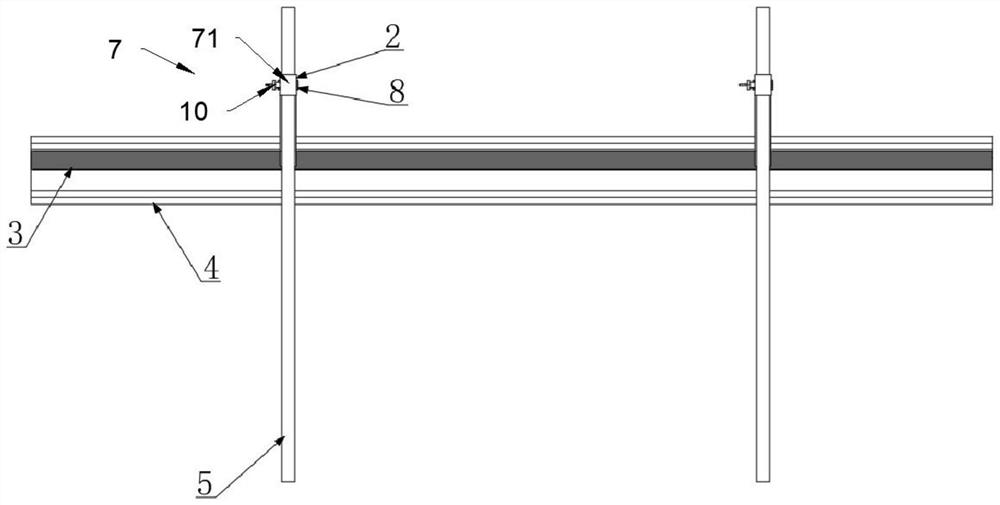

[0037] like figure 1 , figure 2 As shown, the installation device for the longitudinal water stop belt of the second lining of the tunnel described in this embodiment includes a beam 2, a positioning fixture 1 is movably connected with the beam 2, and fasteners 7 are fixed at both ends of the beam 2 to fasten the beam 2. The device 7 is detachably fixed on the surface of the secondary lining steel bar 5.

[0038] Wherein, the positioning fixture 1 includes at least two "L"-shaped angle steel sheets 13, the two "L"-shaped angle steel sheets 13 are symmetrically arranged, and the top of the angle steel sheet 13 is movably connected with the beam 2. Specifically, the top body of the angle steel sheet 13 is connected by connecting pins. 8 is connected with the beam 2 in rotation, and the free ends of the two angle steel sheets 13 (that is, between the clamping ends are used to place the longitudinal water stop 4); The spacing adjustment member 6 can make the free ends of the an...

Embodiment 2

[0049] see Image 6 As shown, this embodiment further improves the design on the basis of the first embodiment. The difference is that the positioning fixture 1 is movably connected with the positioning fixture 1 through the fine-tuning mechanism 14, and the positioning fixture 1 moves left and right along the length direction of the beam 2 through the fine-tuning mechanism 14. , the position of the positioning fixture 1 is fine-tuned left and right, which further facilitates the alignment of the longitudinal waterstop 4 with the construction joint and facilitates the installation of the longitudinal waterstop 4 .

[0050] The fine-tuning mechanism 14 includes a rectangular installation cavity 146 opened along the length of the beam 2 and a rack 141 installed at the inner bottom of the installation cavity 146. A gear set is engaged with the rack 141, and the gear set is rotatably connected to the top of the positioning fixture 1. Drive the gear set to drive the positioning fix...

Embodiment 3

[0058] Please refer to this Figure 8 As shown, this embodiment further improves the design on the basis of the second embodiment. The difference is that for the convenience of a tunnel secondary lining longitudinal waterstop installation device provided in this embodiment, it can adapt to the secondary lining steel bars 5 with different spacings. , the beam 2 is designed in a telescopic structure, and the telescopic structure includes a rectangular strip-shaped telescopic strip 17 arranged at the end of the beam 2. The telescopic strip 17 can move left and right along the length direction of the beam 2 inside the end of the beam 2, so as to achieve adjustment The length of the beam 2 can be adapted to the secondary lining steel bars 5 with different spacings.

[0059] In order to fix the telescopic strip 17 conveniently, a limit bolt 16 is drilled on the surface of the beam 2, the limit bolt 16 is screwed with the beam 2 through a thread, and the tapping end of the limit bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com