Wind driven generator blade root area surface flow control mechanism

A technology of wind power generator and flow control, which is applied to wind power generators, wind power generators consistent with the wind direction, motors, etc. It can solve the problems of water or dust entering the fan blades, affecting the service life, increasing the self-weight of the blades, etc., to prevent water ingress or Dust, increase the service life, ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

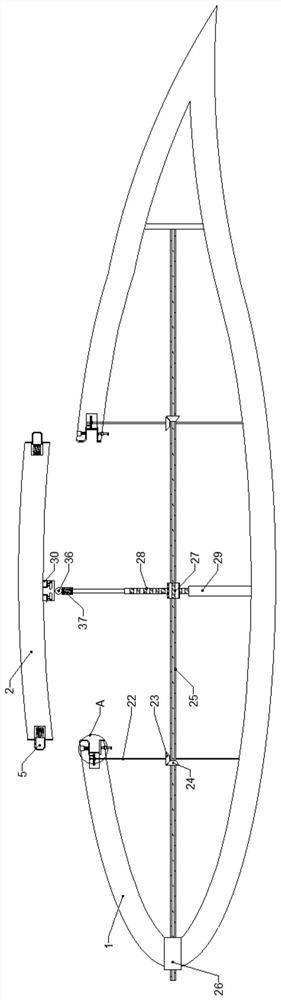

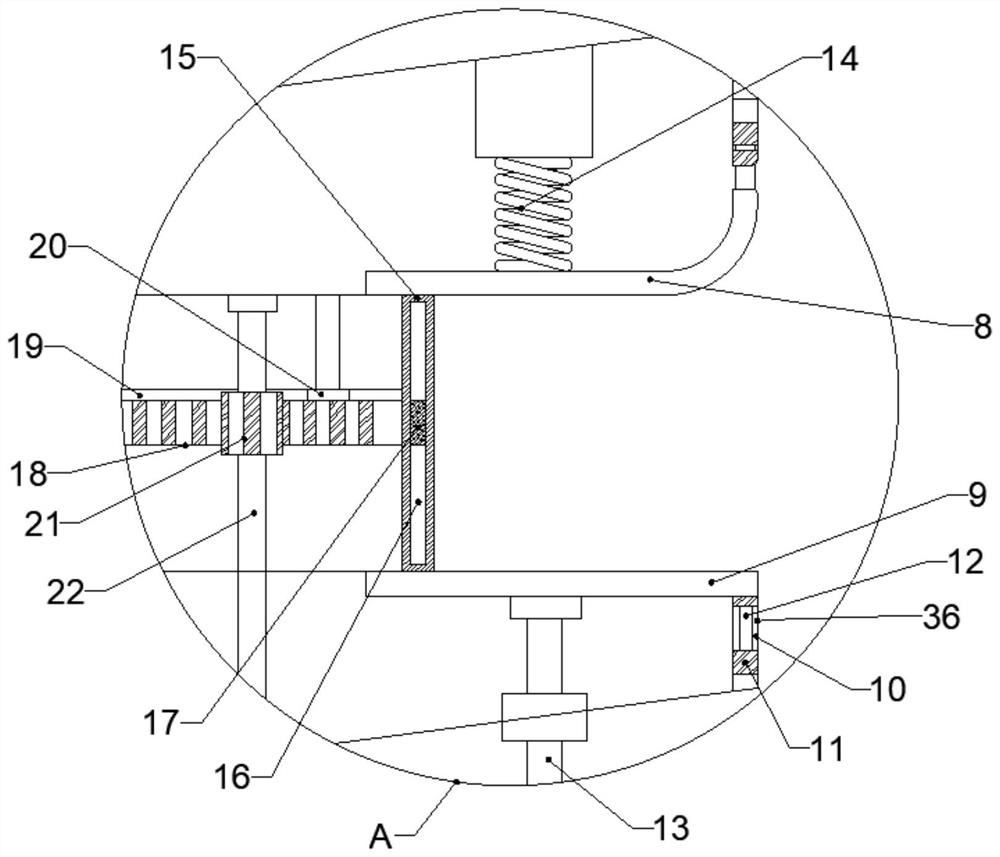

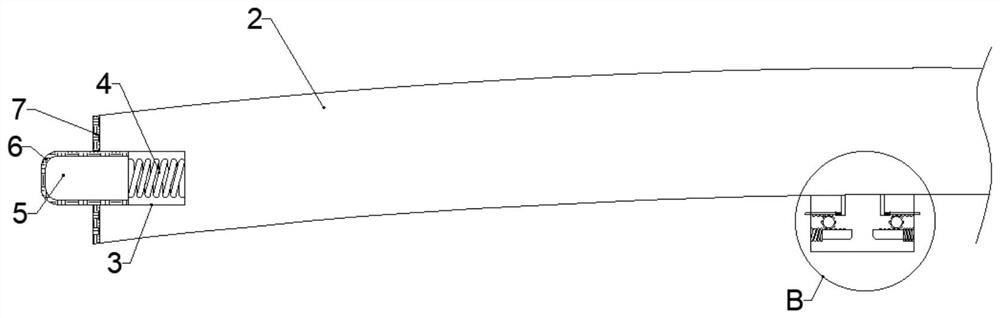

[0021] In this embodiment, a surface flow control mechanism in the root region of a wind turbine blade is as follows: Figure 1-2As shown, it includes a blade 1, a self-vibrating reed 2, a clamping part, a first sealing plate 8, a second sealing plate 9 and a card box 30. The outer surface of the blade 1 is provided with a matching installation for the self-vibrating reed 2 groove, the self-vibrating reed 2 is installed inside the installation groove, the inner wall of the blade 1 close to the end face of the installation groove is installed with a third sealing plate 36, the third sealing plate 36 is perpendicular to the inner wall of the blade 1, and the number of the third sealing plate 36 is Two, two third sealing plates 36 are installed opposite to each other, a sealing groove 10 is opened inside the third sealing plate 36, a sliding plate 12 is slidably connected inside the sealing groove 10, and one end of the sliding plate 12 located inside the sealing groove 10 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com