Emptying valve of air suspension centrifugal blower

A centrifugal blower, air suspension technology, applied in the direction of balance valve, valve device, valve details, etc., can solve the problem of reducing the sealing performance of the inner cylinder and the film body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

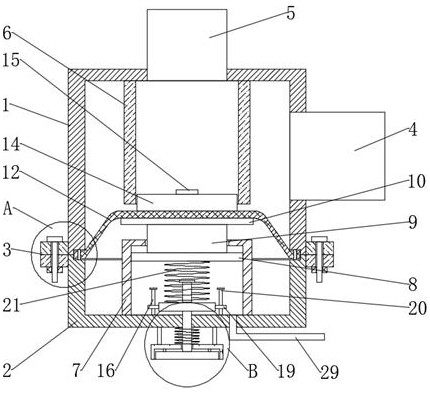

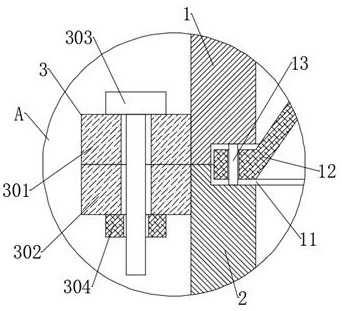

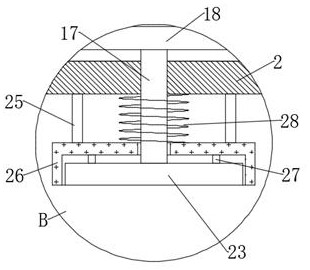

[0030] like Figure 1-7 As shown, the embodiment of the present invention provides an air suspension centrifugal blower vent valve, including an upper casing 1 and a lower casing 2, the upper casing 1 and the lower casing 2 are installed together by a connecting assembly 3, and the connecting assembly 3 includes a first A connecting flange 301 , a second connecting flange 302 , a first fastening bolt 303 and a nut 304 , the first connecting flange 301 is fixedly connected to the upper casing 1 , and the second connecting flange 302 is fixedly connected to the lower casing 2 Above, the number of the first tightening bolts 303 and nuts 304 is set in multiples, and the first tightening bolts 303 and nuts 304 are arranged correspondingly, and the connection between the upper casing 1 and the lower casing 2 is provided with a mounting groove 11, The inner bottom of the installation groove 11 is fixedly connected with a fixed rod 13, and the number of the fixed rods 13 is set in mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com