Telescopic method based on screw telescopic push rod

A screw and push rod technology, applied in electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of large occupied space, small occupied space, complicated structure of telescopic push rods, etc., and achieve small occupied space. , high reliability, simple expansion method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

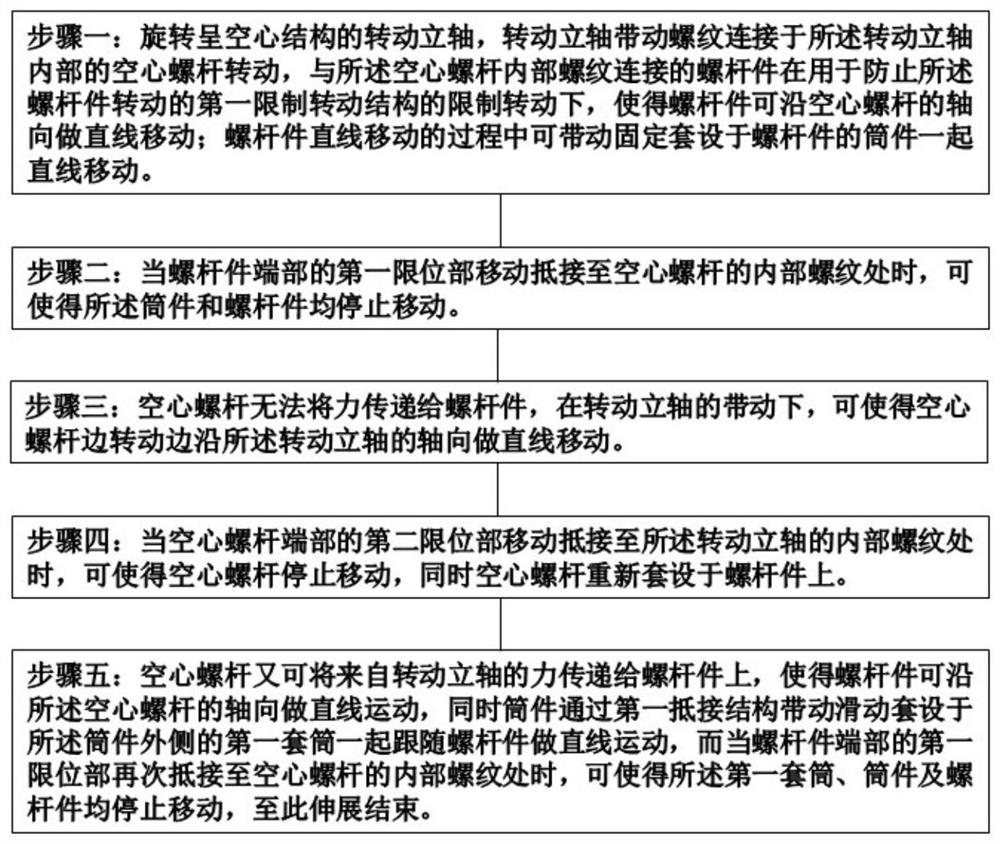

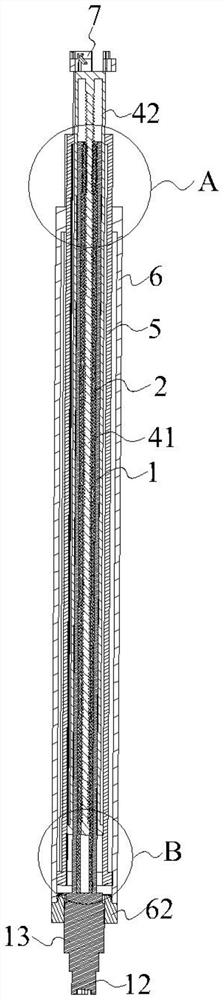

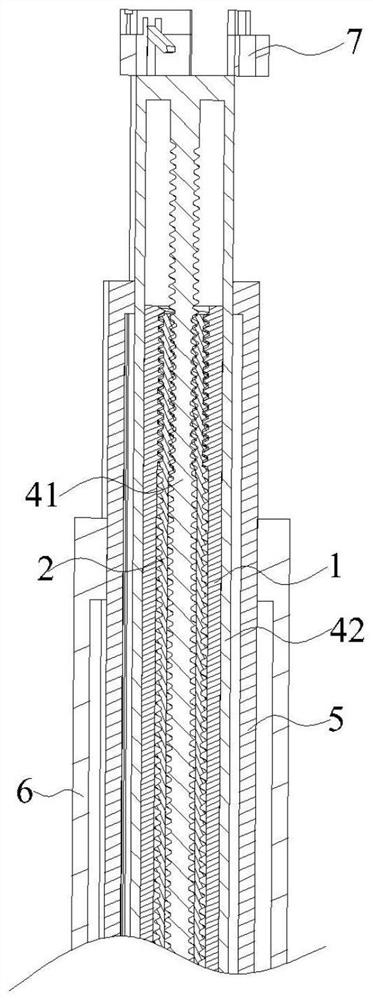

[0056] like Figure 1-Figure 23 Shown is an embodiment of a telescopic method based on a screw telescopic push rod, which specifically includes the following steps:

[0057] Step 1: Rotate the rotating vertical shaft 1 with a hollow structure, the rotating vertical shaft 1 drives the hollow screw 2 threadedly connected to the inside of the rotating vertical shaft 1 to rotate, and the screw member 41 threadedly connected with the hollow screw 2 is used to prevent the Under the restricted rotation of the first rotation-restricting structure for the rotation of the screw member 41, the screw member 41 can move linearly along the axial direction of the hollow screw 2; during the linear movement of the screw member 41, it can drive the cylinder fixedly sleeved on the screw member 41. Pieces 42 move linearly together;

[0058] Step 2: When the first limiting portion 411 at the end of the screw member 41 moves and abuts against the inner thread of the hollow screw 2, the cylinder me...

Embodiment 2

[0086] This embodiment is Embodiment 2 of a telescopic method based on a screw telescopic push rod. The screw telescopic push rod used in this embodiment is different from the screw telescopic push rod used in Embodiment 1 in that: this embodiment Zhongru Figure 20 As shown, one end of the second sleeve 6 is detachably connected with an end cover 62. In this embodiment, the end cover 62 is screwed on the second sleeve 6, and the end cover 62 is movably sleeved on the gear shaft 13, so that it is convenient to thread The disassembly and assembly of the telescopic push rod is very convenient to use.

Embodiment 3

[0088] This embodiment is Embodiment 3 of a telescopic method based on a screw telescopic push rod. The screw telescopic push rod used in this embodiment is different from the screw telescopic push rod used in Embodiment 2 in that: this embodiment The outer wall of the first limit ring 43 is provided with a first protruding strip 81 along the axial direction of the first limit ring 43 , and the inner wall of the first sleeve 5 is provided with a second limit along the axial direction of the first sleeve 5 . The grooves 82 and the first protruding strips 81 are inserted into the first grooves 82 , which can further improve the stability of the movement of the cylindrical member 42 in the first sleeve 5 . A plurality of first protruding strips 81 are provided, and a plurality of first protruding strips 81 are evenly distributed on the first limiting ring 43 along the circumferential direction of the first limiting ring 43 , wherein several first grooves 82 are provided, A plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com