Device for fixing circuit

A technology for fixing lines and fixing parts, applied in the field of pipes or hoses, and cables, it can solve the problems of difficult assembly, high number of components, etc., and achieve the effect of simple calibration, ensuring holding force, and uniform force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

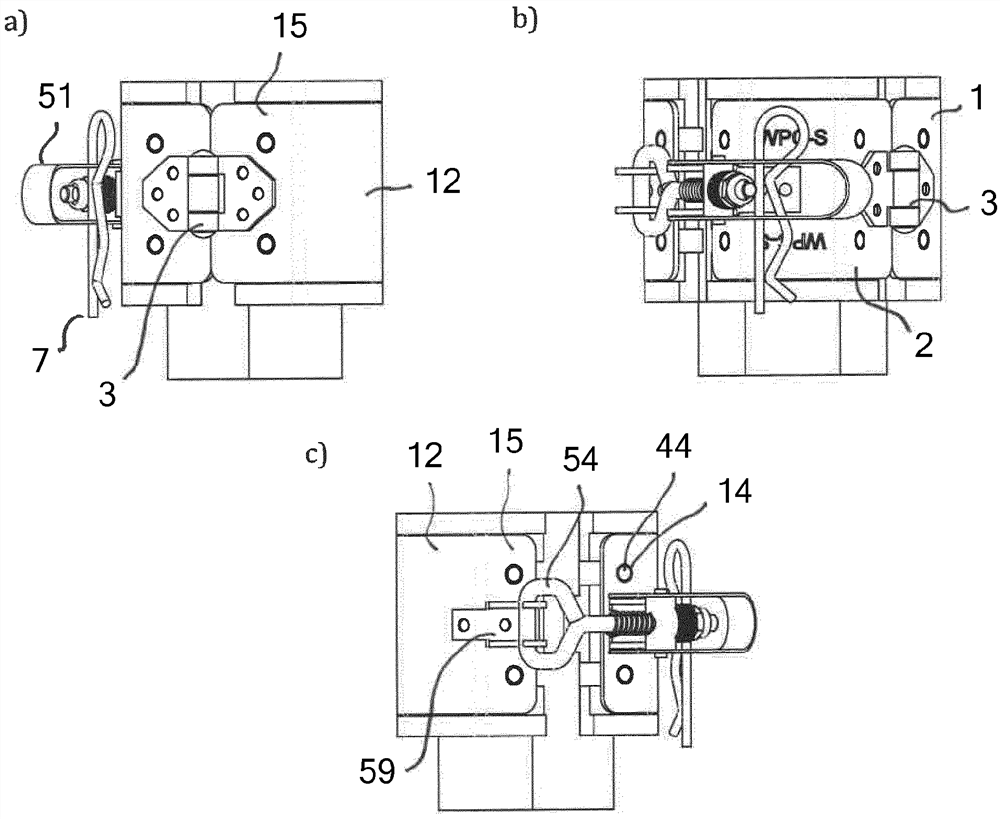

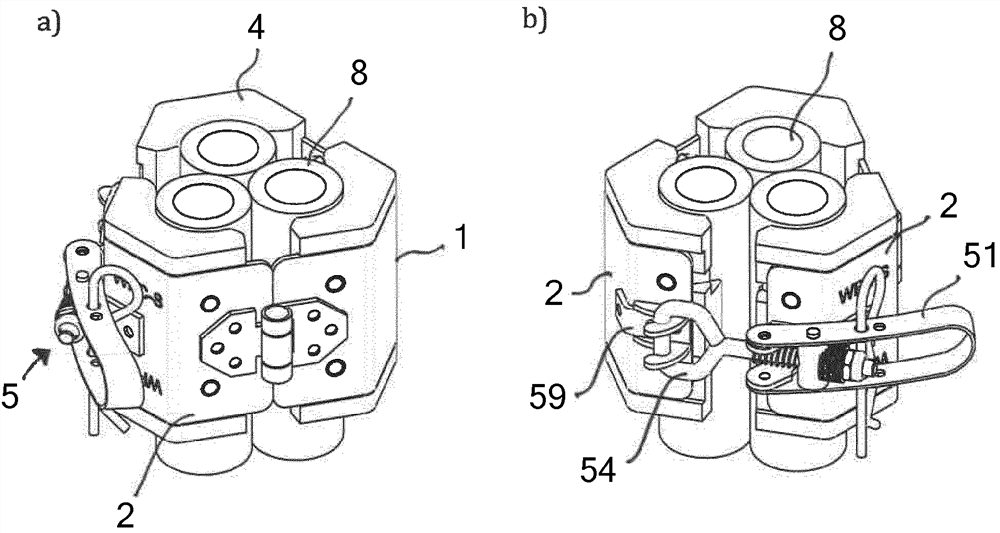

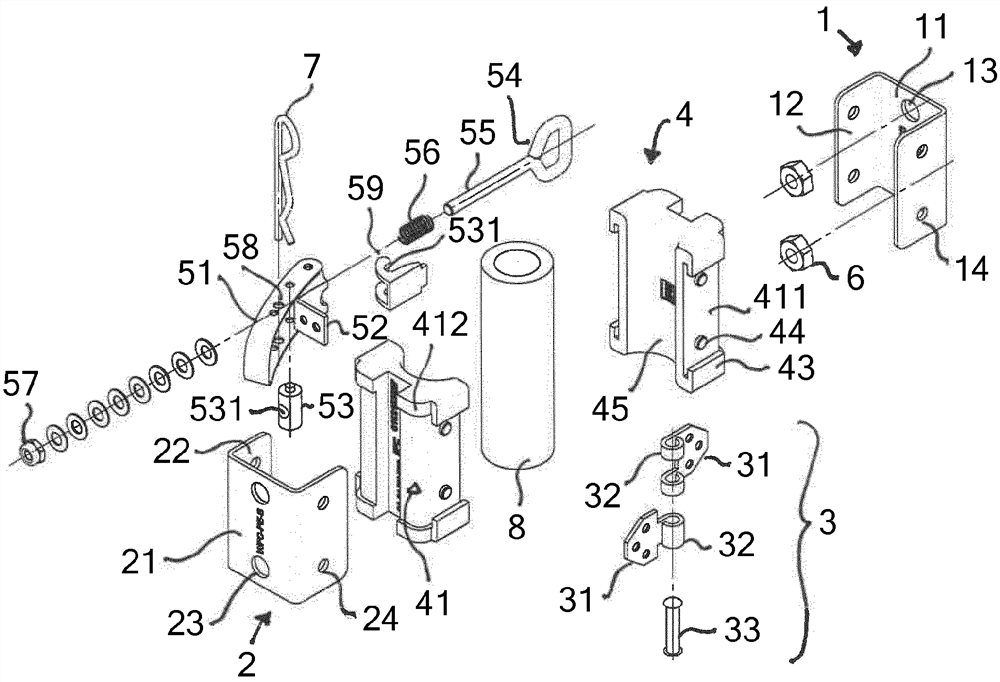

[0035] The device chosen as an example for fixing lines, in particular electrical lines, in a tower of a wind power installation comprises a first clip part 1 and a second clip part 2 which are connected to each other in an articulated manner via a hinge 3 and which The clamping blocks 4 are each accommodated, wherein a tensioning closure 5 is arranged, via which the two clamping parts 1 , 2 can be tensioned relative to each other.

[0036] on the basis of figure 1 In the exemplary embodiment of the present invention, the two clip parts 1 , 2 are embodied as identical C-shaped sheet metal bent parts and have end sides 11 , 21 , on whose longitudinal sides two oppositely arranged lateral wings 12 , 22 are molded. The flanks 12 , 22 are placed at right angles to the end sides 11 , 21 at these end sides. In the middle, two bores 13 , 23 are introduced into the end sides 11 , 21 at a distance from each other. In alignment with the holes 13 , 23 , to the end sides 11 , 21 , on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com