Determining size of leak in fuel tank system

A technology for fuel tanks and leaks, applied in the field of vehicle diagnosis, can solve the problems of less idling phase, increased consumption, and inability to perform diagnosis frequently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

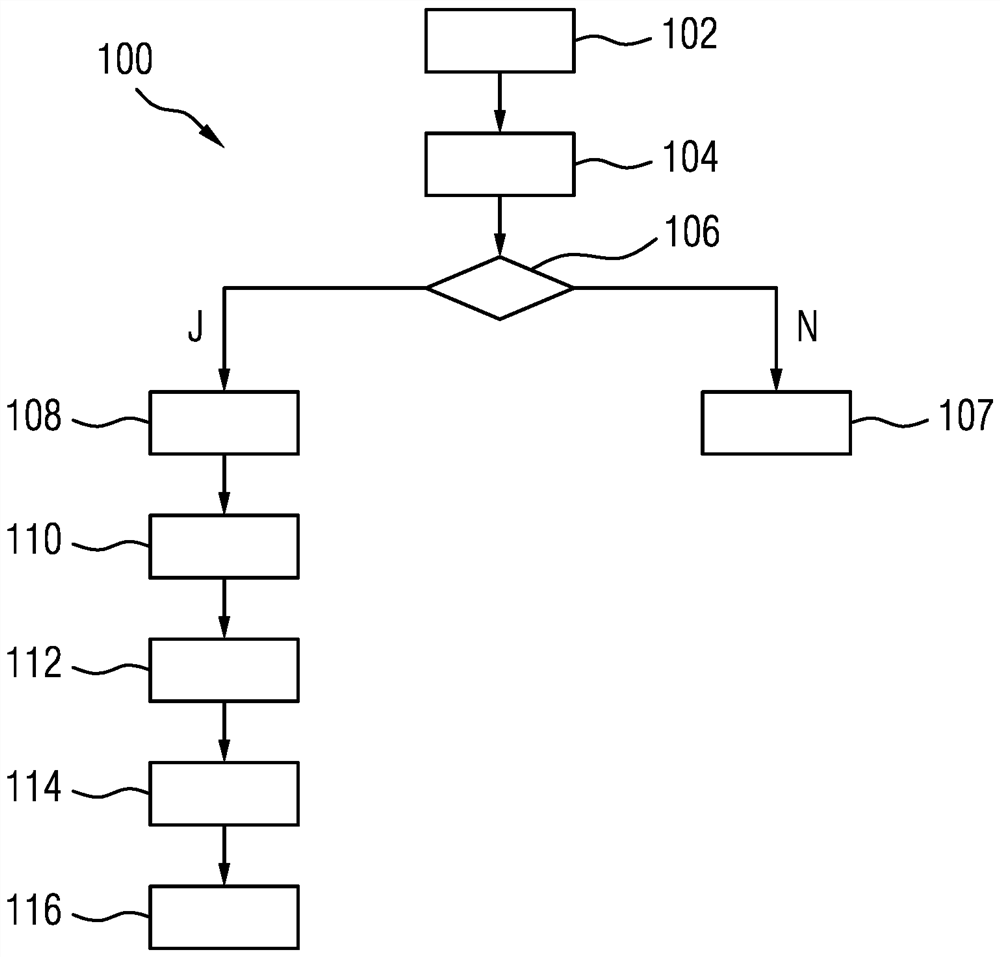

[0031] figure 1A flowchart is shown of a method 100 according to the invention for determining the size of a leak in a fuel tank system of a vehicle with an internal combustion engine. At 102 , the internal combustion engine of the vehicle is started and at 104 one or more parameter values are determined, which are decisive for the further method sequence. These parameter values may in particular be the parking time of the vehicle, ie how long the vehicle has been parked before starting 102, and / or the difference between the fuel temperature in the tank system and the ambient temperature. Importantly, a statement about the quiescence and stability of the fuel in the tank can be derived from the parameter value / values. It is then checked (using the determined parameter value) whether at least one of the plurality of diagnostic conditions is satisfied at 106 . If the parking time is longer than the predetermined minimum parking time, for example, a first diagnosis conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com