Bearing cover and bearing cover positioning method

A positioning method, technology of bearing caps, applied in the direction of shafts and bearings, bearing elements, rigid supports of bearing components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

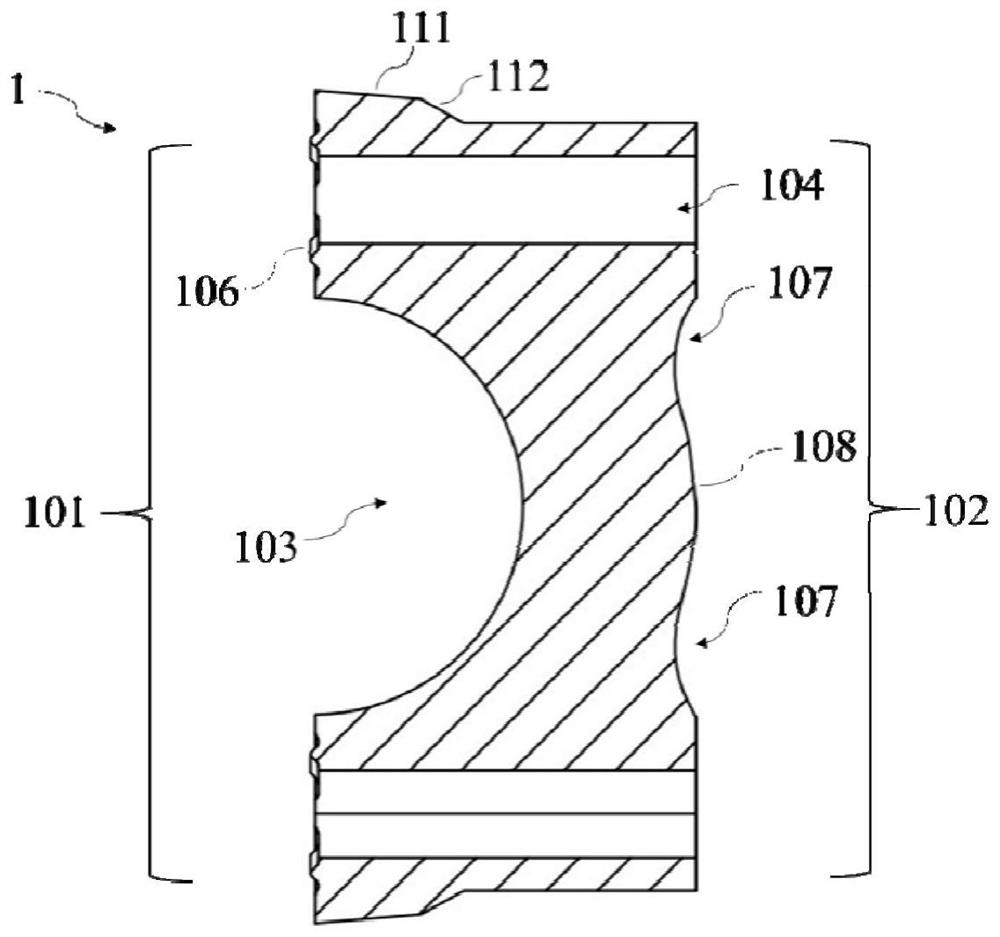

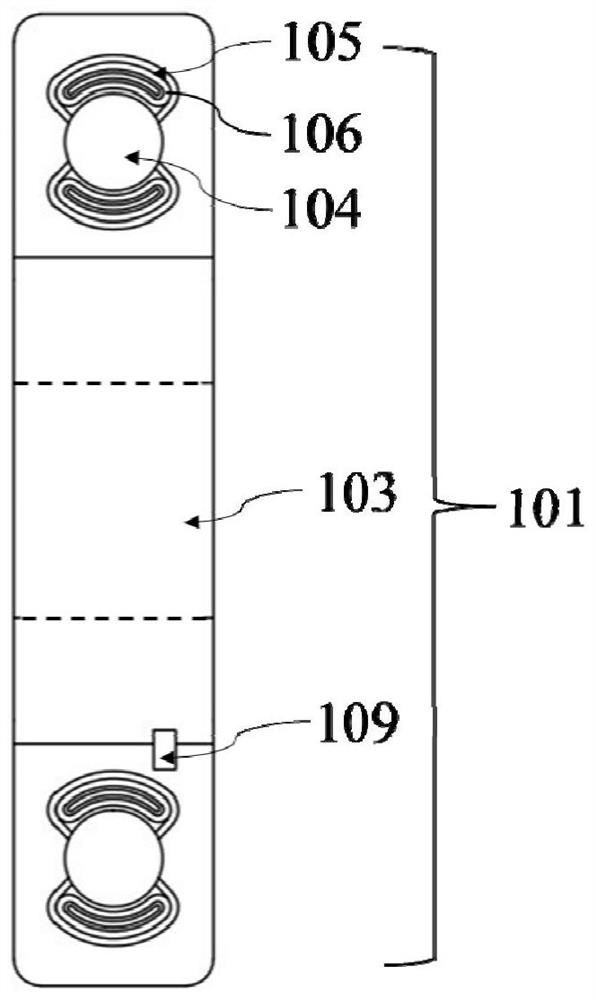

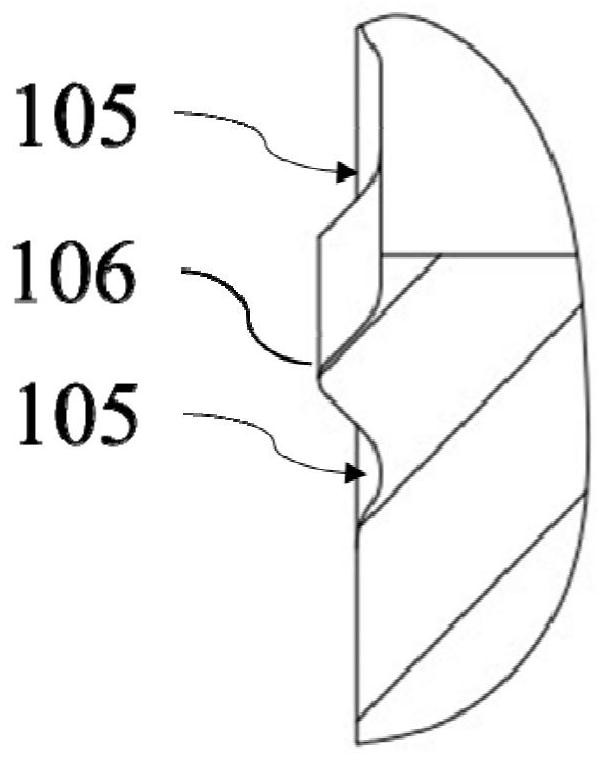

[0026] like figure 1 as well as figure 2 As shown, this embodiment provides a bearing cap 1 that is pressed and sintered by powder metallurgy, the bearing cap 1 has a first mounting surface 101 and a second mounting surface 102 that is away from the first mounting surface 101, The bearing cover 1 further includes a bearing installation groove 103 , two bolt installation holes 104 , four grooves 105 and two raised portions 106 . Wherein, the bearing installation groove 103 is recessed into the bearing cover 1 from the first installation surface 101 ; two bolt installation holes 104 are respectively disposed on opposite sides of the bearing installation groove 103 . The bolt mounting holes 104 penetrate from the first mounting surface 101 to the second mounting surface 102; such as figure 2 as well as image 3 As shown, the protruding portion 106 is disposed on the first mounting surface 101 and the groove 105 surrounds the protruding portion 106. The protruding portion 106...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com