Anesthesia puncture needle structure

A technology of puncture needles and needles, which is applied in the field of medical equipment, can solve the problems of easy confusion, inaccurate distinction, needle bending and other problems, and achieve the effect of high injection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

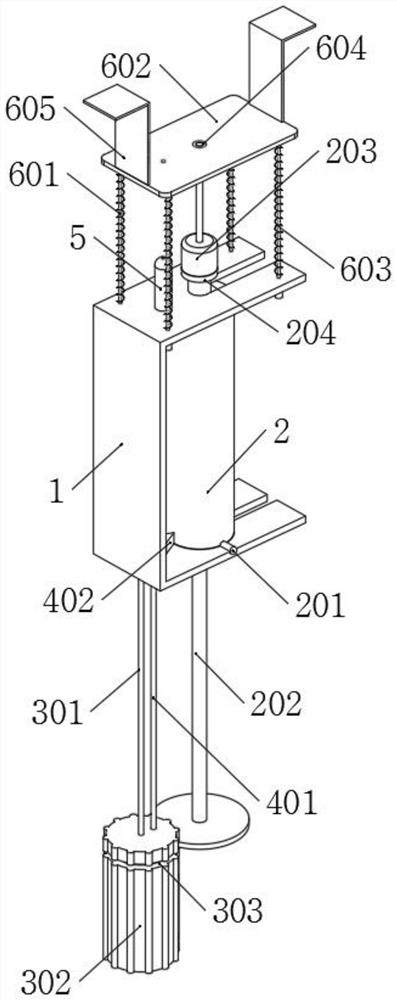

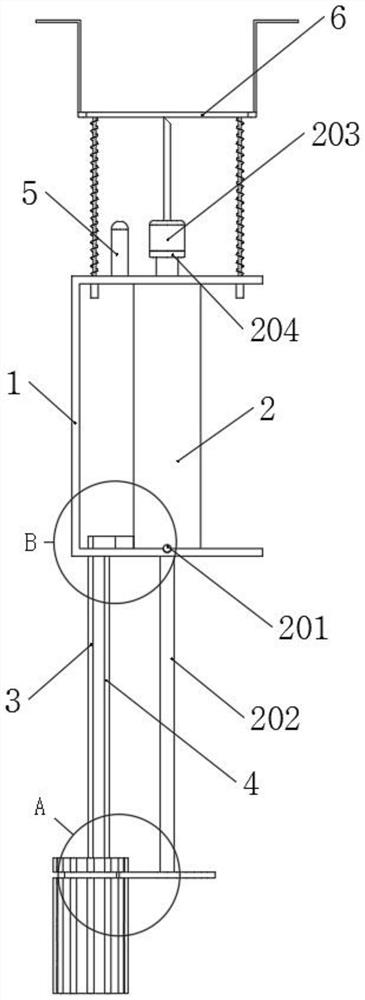

[0036] Example: please refer to Figure 1 to Figure 8 :

[0037] The present invention proposes an anesthesia puncture needle structure, comprising: a base body 1, a syringe tube 2, a propelling part 3, a marking part 4 and a cleaning part 6;

[0038] The seat body 1 is a concave structure, and the syringe barrel 2 is installed in the seat body 1, and the laser detector 5 is installed on the seat body 1;

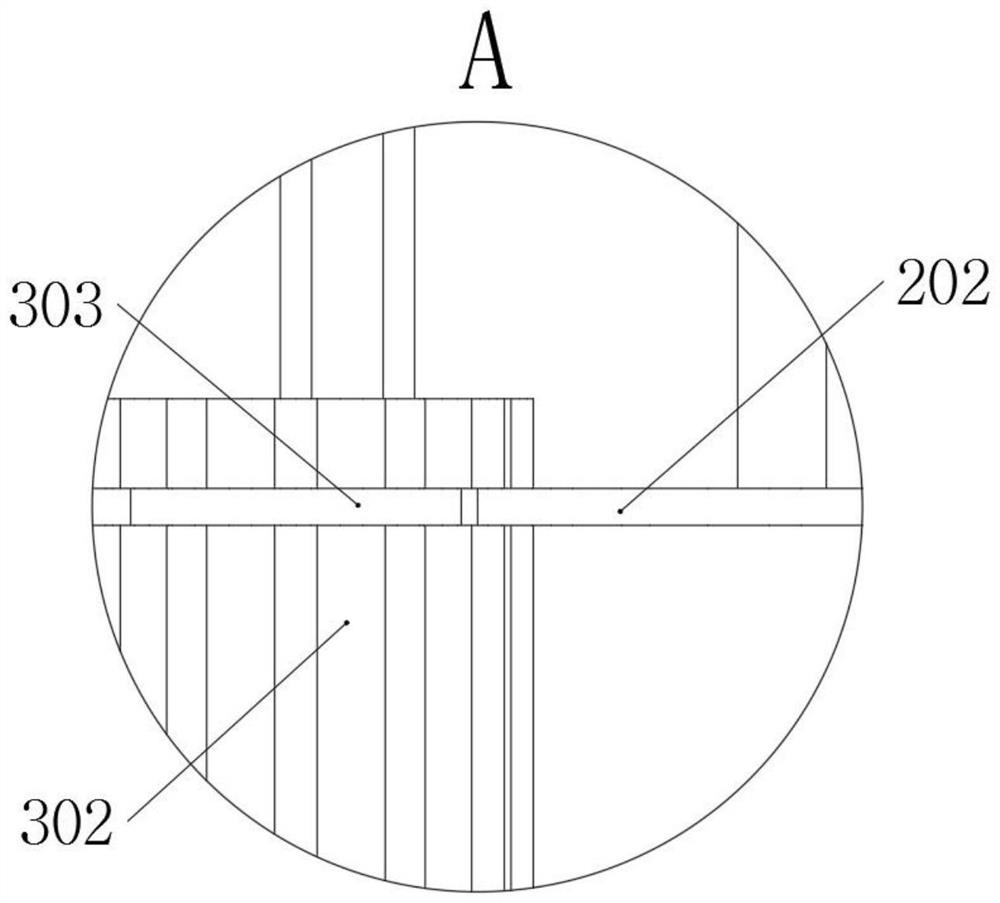

[0039] The advancing part 3 is composed of a threaded rod 301, a handle B302 and a clamping slot B303, and the threaded rod 301 is threadedly connected to the seat body 1;

[0040] The marking part 4 consists of a sliding rod A401 and a cutter 402, and the sliding rod A401 is slidably connected to the base body 1;

[0041] The cleaning part 6 is composed of a sliding rod B601, a protective plate 602, an elastic member 603, a cleaning cotton 604, a through hole 605 and a support arm 606, and there are four sliding rods B601 in total, and the four sliding rods B601 are all s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com