Clean briquette coal processing equipment and treatment method thereof

A processing method and coal processing technology, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve the problems of fragility, residue, and inconvenient maintenance, and achieve the effect of reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

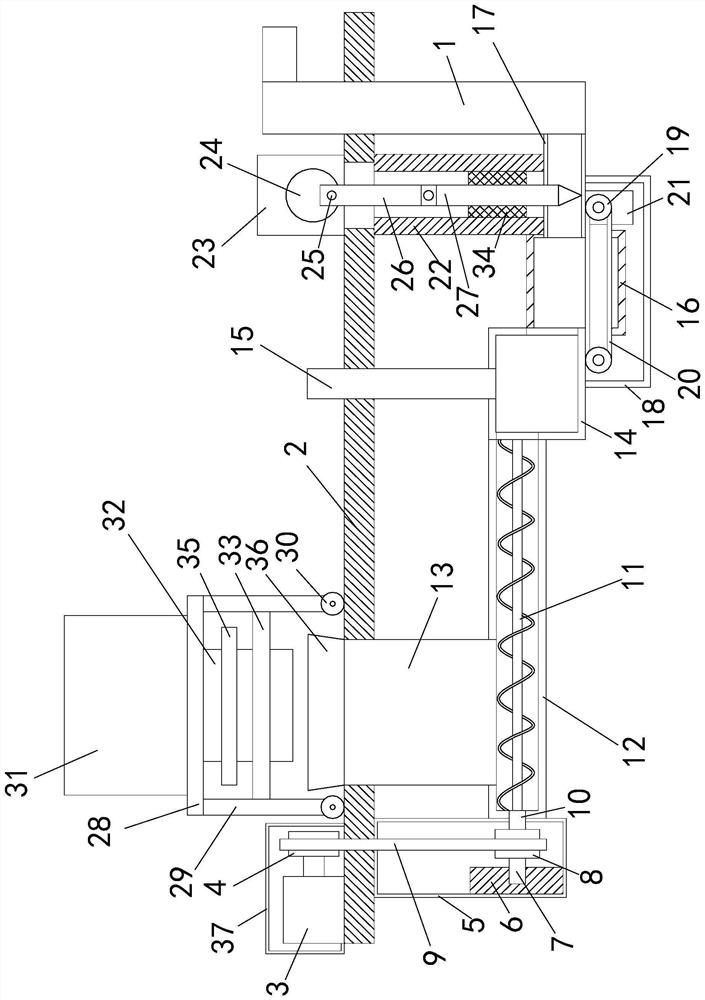

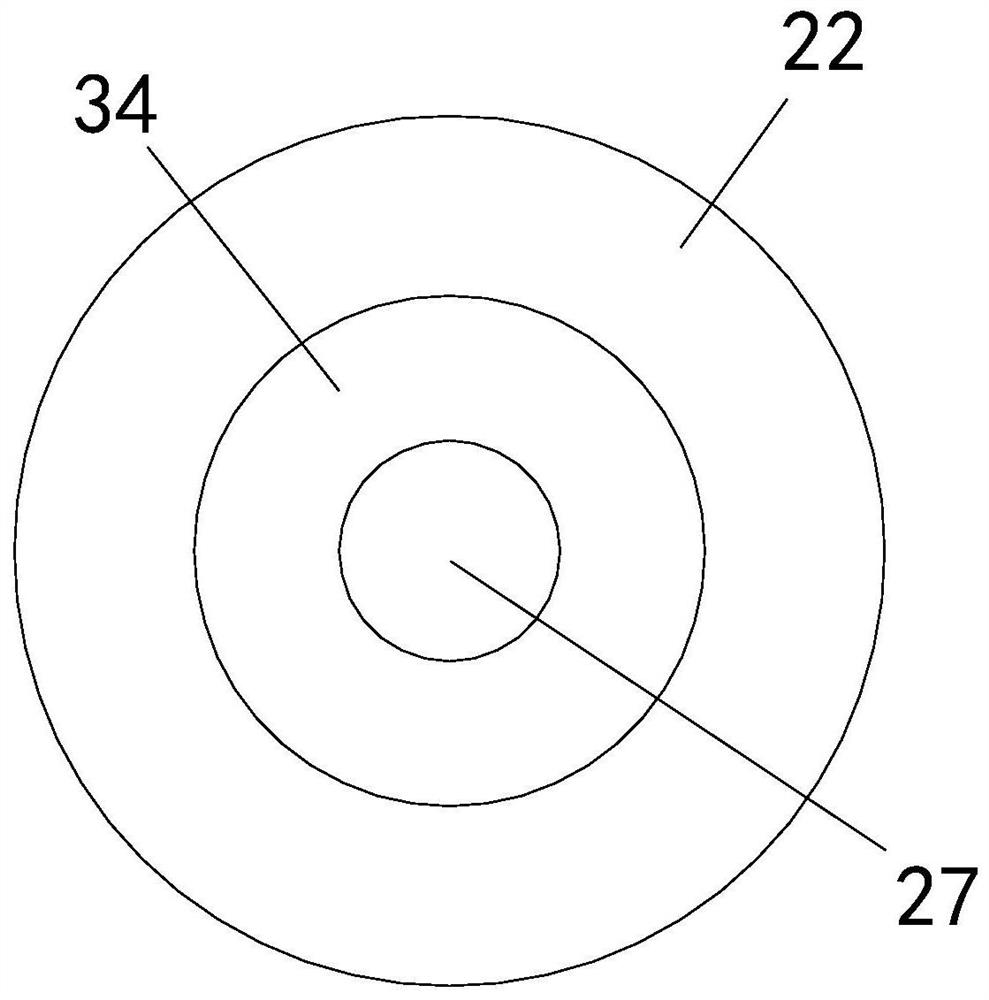

[0033] 3. See Figure 1-4 , a clean briquette processing equipment and a processing method thereof, comprising a lifting conveyor 1 and a frame plate 2, the top left part of the frame plate 2 is fixedly connected with a first motor 3, and the outside of the first motor 3 is sleeved There is a protective shell 37; the first motor 3 is protected by the protective shell 37 to reduce the damage of the first motor 3. The output shaft end of the first motor 3 is fixedly connected with the driving wheel 4, and the bottom of the frame plate 2 is fixedly connected. The left part of the end is fixedly connected with a support box 5, the left end of the inner wall of the support box 5 is fixedly connected with a support base 6, the middle part of the right end of the support base 6 is rotatably connected with a horizontal shaft 7, and the right end of the horizontal shaft 7 is fixedly connected with a The driven wheel 8, the driven wheel 8 and the driving wheel 4 are connected by a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com