Screening device with multi-stage separation function for coal mine

A screening device and screening technology, applied in the direction of separating solids from solids with airflow, filtering, solid separation, etc., can solve problems such as inability to handle pulverized coal, improve screening efficiency, and avoid uneven thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

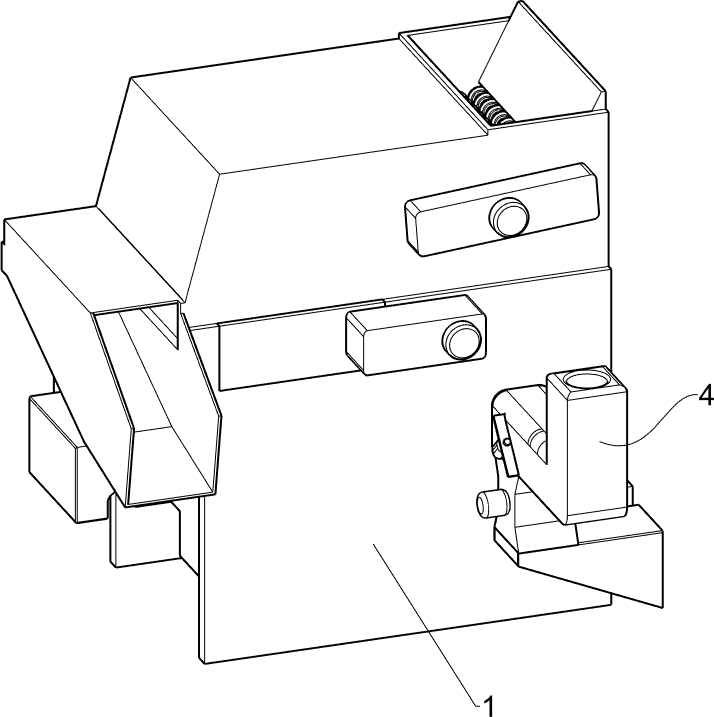

[0029] A screening device with multi-stage separation function for coal mines, such as Figure 1-Figure 8 As shown, it includes a screening shell 1, the upper right side of the screening shell 1 is provided with a feeding port for coal entry, and the lower side of the right portion of the screening shell 1 is provided with a discharge port for cinder removal, screening The upper left side of the shell 1 is provided with a feeding port inclined to the lower side. The feeding port of the screening shell 1 is used to remove larger coal lumps after screening. An electric conveyor 101 for conveying coal lumps to the left is installed, an upper screening mechanism 2 for primary screening of coal lumps is installed in the upper part of the screening shell 1, and a lower part of the screening shell 1 is installed for The lower screening mechanism 3 and the upper screening mechanism 2 for re-screening perform primary screening for the size of the coal lumps conveyed to the left, and th...

Embodiment 2

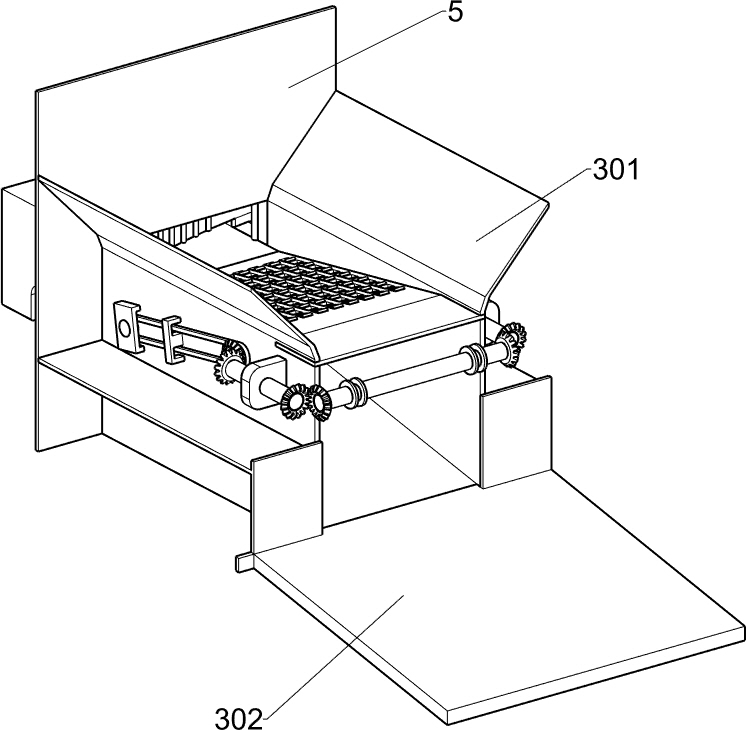

[0032] On the basis of Example 1, as Figure 2-Figure 5 As shown, the upper screening mechanism 2 includes a mounting shell 201, the mounting shell 201 is fixed on the inner right part of the screening shell 1, the mounting shell 201 is located on the lower left side of the electric conveyor 101, and the upper left side of the mounting shell 201 is welded with a fixed Shell 202, the upper and lower parts of the fixed shell 202 are set to be conical, which is convenient for the coal lumps to be transported to the left and then fall down when the flow is divided, so as to avoid the coal lumps from accumulating together and causing inconvenience to the coal lump screening work. The front and rear parts of the side are provided with first sieve plates 203 for primary screening of coal blocks. The left parts of the two first sieve plates 203 are provided with a number of rectangular through holes for coal blocks to pass through. The upper side of a sieve plate 203 is provided with ...

Embodiment 3

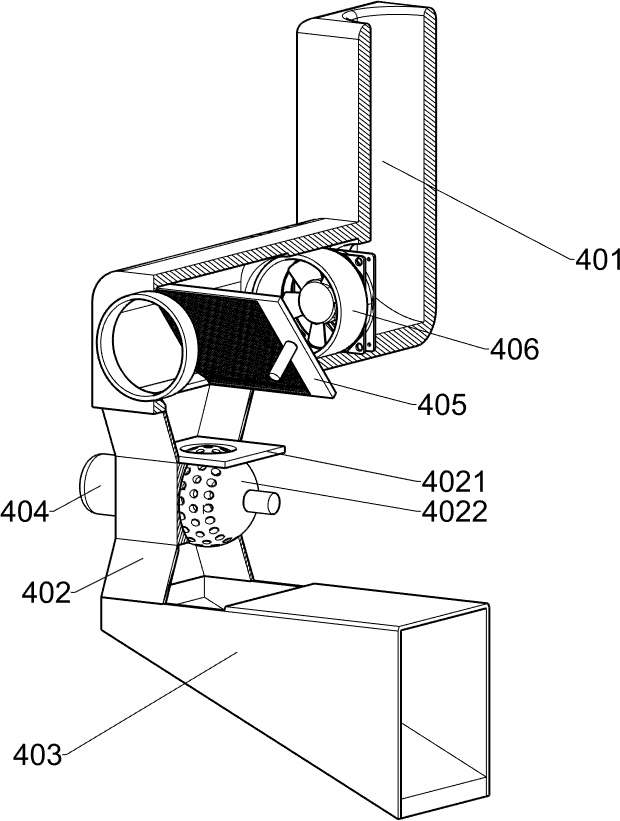

[0040] On the basis of Example 2, as Figure 9 As shown, it also includes a purification mechanism 4. There are two purification mechanisms 4. The two purification mechanisms 4 are respectively installed on the front and rear parts of the screening shell 1 through fixed pipes. The purification mechanism 4 is used to filter the pulverized coal. 4. It includes a suction casing 401, which is installed on the front of the screening casing 1 through a fixed pipe, and the suction casing 401 is L-shaped. In the discharge shell 403, the upper and lower parts of the communication shell 402 are in the shape of outward flares, the middle part of the communication shell 402 is a vertical pipe, and a sealing gasket 4021 is installed in the upper part of the communication shell 402, and the sealing gasket 4021 is set to a soft material, A sealing ball 4022 is rotatably provided in the middle of the communication shell 402 through a rotating rod. The outer side of the sealing ball 4022 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com