Secondary processing device for cross-linked polypropylene foaming sheet

A technology for cross-linked polypropylene and secondary processing, which is applied in the field of secondary processing devices for cross-linked polypropylene foam sheets, can solve problems such as the inability to automatically dose additives in a quantitative manner, improve mixing effect, reduce waste, and improve output. The effect of material efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

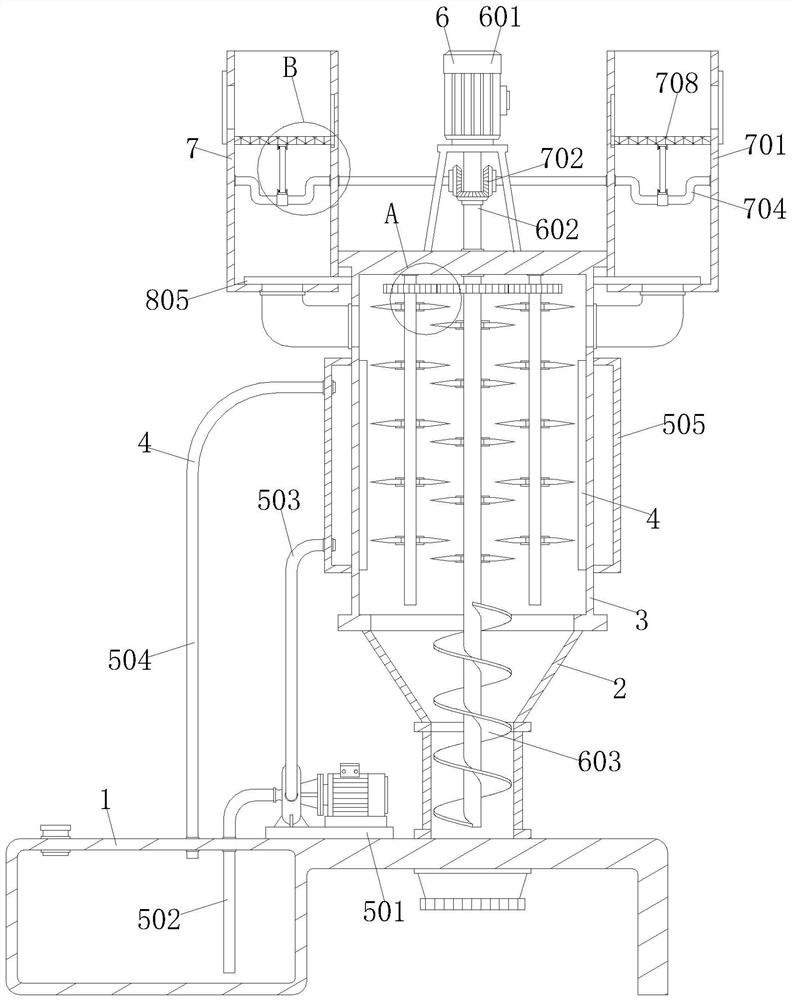

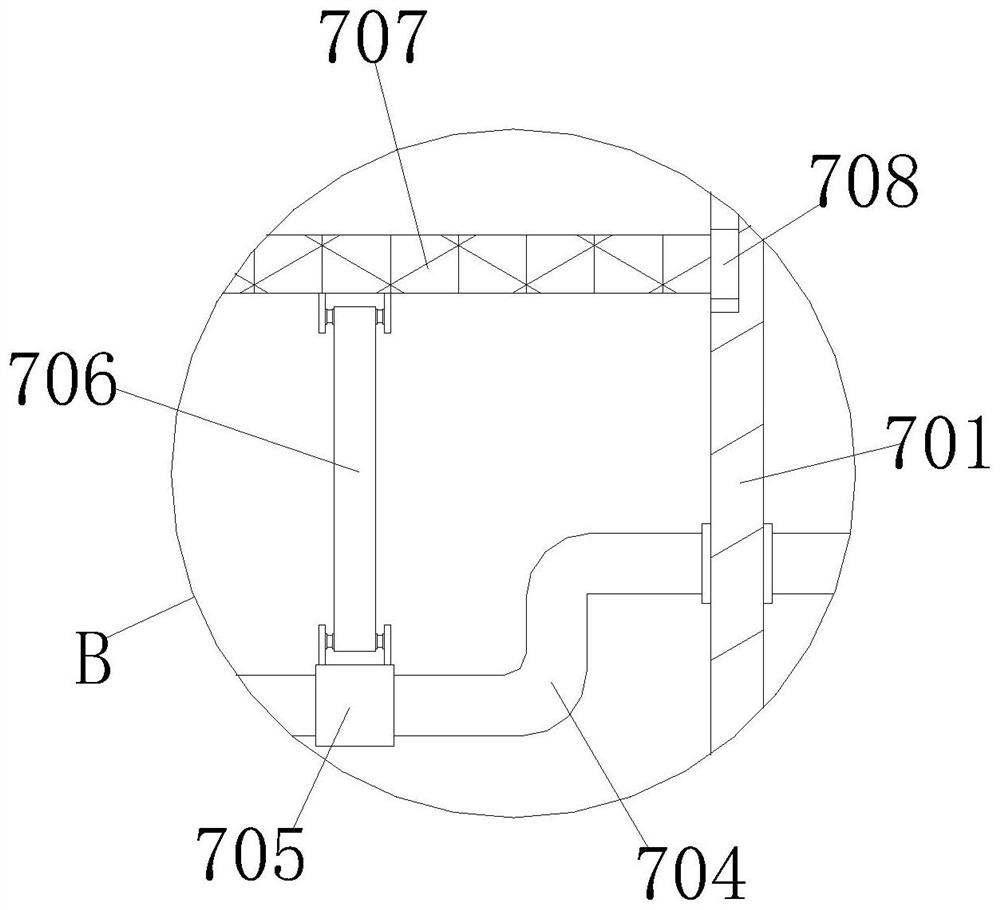

[0031] see Figure 1-6, the present invention provides a technical solution: a secondary processing device for cross-linked polypropylene foam sheets, including a working platform 1, a cooling mechanism 5, a stirring mechanism 6, a screening mechanism 7 and a quantitative feeding mechanism 8, which work The top of the platform 1 is welded and installed with a discharge box 2, the top of the discharge box 2 is fixedly installed with a mixing box 3, the inner walls on both sides of the mixing box 3 are fixedly installed with electric heating plates 4, and the outer walls on both sides of the mixing box 3 are fixedly connected. There is a feeding pipe B and is communicated with its interior, the rear side of the mixing box 3 is fixedly connected with a feeding pipe A and communicated with its interior, and the cooling mechanism 5 includes a circulating water pump 501 and an L-shaped water inlet pipe 502 arranged on the top of the working platform 1. The bottom of the water pump 5...

Embodiment 2

[0033] see Figure 1-6 On the basis of the first embodiment, the cooling mechanism 5 includes an L-shaped water outlet pipe 503, an L-shaped water exchange pipe 504 and a cooling tank 505, a water storage cavity is opened inside the working platform 1, and the other end of the L-shaped water inlet pipe 502 extends to Inside the water storage cavity, the output end of the circulating water pump 501 is fixedly connected to the other end of the L-shaped water outlet pipe 503, one end of the L-shaped water outlet pipe 503 extends to the interior of the cooling tank 505, and the other end of the L-shaped water exchange pipe 504 is connected to the working platform The top of 1 is fixedly connected and the other end of the L-shaped water exchange pipe 504 extends to the interior of the water storage cavity.

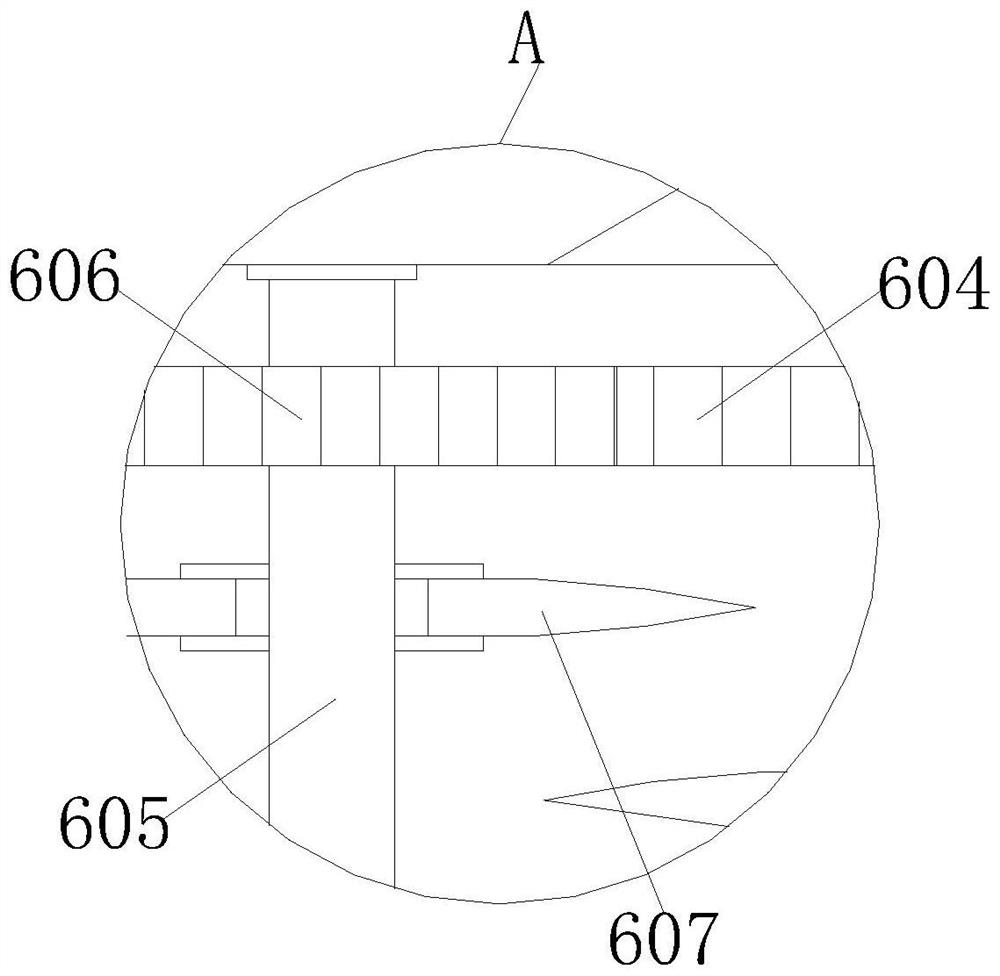

[0034] Further, the stirring mechanism 6 includes a reduction motor 601, a rotating rod 602, a helical blade 603, a driving gear 604, a rotating rod 605, a driven gear 606 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com