Monitoring data acquisition system and method for injection molding machine in monitoring process

A technology for monitoring data and obtaining systems, which is applied in the field of injection molding machines, can solve problems such as large memory space, and achieve the effects of improving production efficiency, saving manpower, and saving time for troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

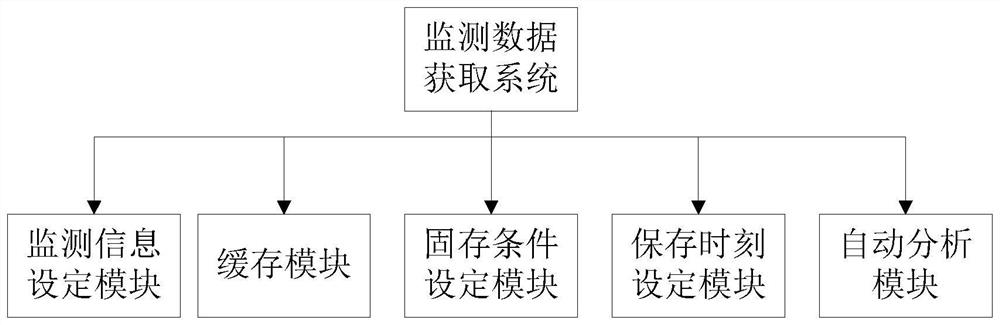

[0030] In order to solve the problem in the prior art, when a failure occurs in the process of monitoring the production of the injection molding machine, technicians are often required to go to the site to reproduce the problem, and monitor the corresponding function or injection action through the tool to deal with it, and in the monitoring process When most of the monitoring data are saved, there is no mechanism to trigger the save, so that the problem of occupying a lot of memory space, such as figure 1 As shown, the present invention proposes a monitoring data acquisition system for an injection molding machine in a monitoring process, including:

[0031] The monitoring information setting module is used to set the monitoring data to be acquired in the monitoring process;

[0032] The monitoring data in the monitoring information setting module includes:

[0033] Communication data packets, signal input and output data packets, alarm information, parameter change informa...

Embodiment 2

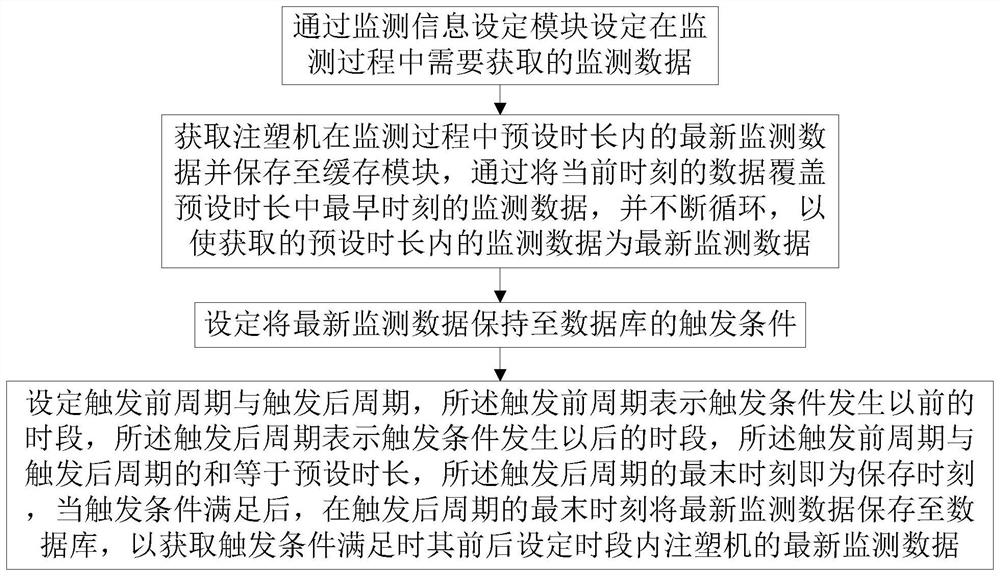

[0079] like figure 2 As shown, the present invention also provides a monitoring data acquisition method for an injection molding machine in a monitoring process, including:

[0080] Set the monitoring data to be acquired in the monitoring process through the monitoring information setting module;

[0081] Obtain the latest monitoring data of the injection molding machine within the preset period of time during the monitoring process and save it to the cache module. By overwriting the current moment's data over the monitoring data at the earliest moment in the preset period of time, and looping continuously, so that the acquired preset period of time is within the specified period of time. The monitoring data are the latest monitoring data;

[0082] Set the trigger condition to keep the latest monitoring data to the database;

[0083] Set the pre-trigger period and the post-trigger period, the pre-trigger period represents the period before the trigger condition occurs, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com