Manufacturing equipment of environment-friendly moisture-proof composite rock wool board

A kind of rock wool board and environment-friendly technology, which is applied in the field of production equipment of environment-friendly moisture-proof composite rock wool board, can solve the problems of trouble to take out, waste of raw materials, scattered particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

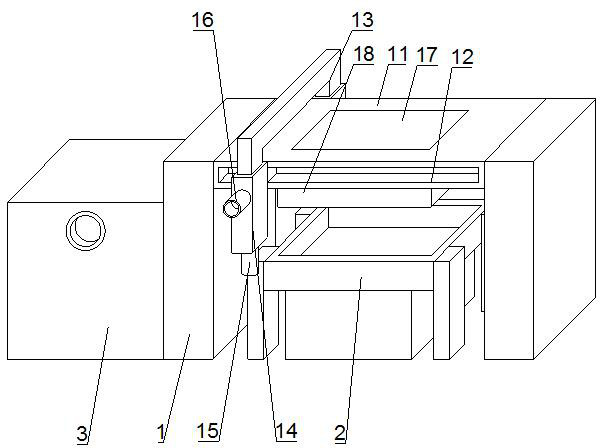

[0038] like Figure 1-6 As shown, the present invention provides an environment-friendly moisture-proof composite rock wool board production equipment, including composite rock board production equipment 1, composite rock board shaping table 2 and rock board debris collector 3, composite rock board production equipment A slate chip collector 3 is arranged inside the device 1 , and a slate chip collector 3 is detachably installed on the left outer surface of the composite slate production equipment device 1 .

[0039] In this embodiment, the granulated raw material is extruded and plasticized by the composite slate shaping table 2 and the composite slate production equipment 1, and the excess particles are collected by the composite slate production equipment 1 through the slate debris collection. to the inside of the device 3.

Embodiment 2

[0041] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a casing plate 11 is provided on the outside of the top of the composite rock slab manufacturing equipment 1, and the outer surfaces of the front and rear sides of the casing plate 11 are A sliding track 12 is provided on the upper surface of the sliding track 12, and a supporting slider 13 is slidably overlapped on the outer surface of the sliding track 12. A suction fan 14 is arranged on the outer surface of one side of the supporting slider 13, and a suction fan 14 is arranged on the outer surface of the bottom of the exhaust fan 14. The material port 15, the outer surface of the support slider 13 is provided with a material guide pipe 16, the top inner surface of the rock board debris collector 3 is detachably connected with a partition 31, and the bottom outer surface of the partition 31 is hingedly connected There is a deceleration baffle 32, a...

Embodiment 3

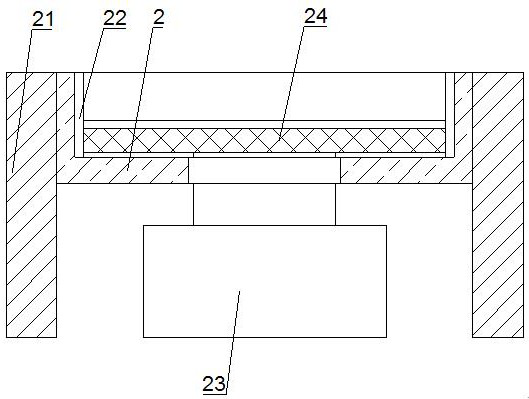

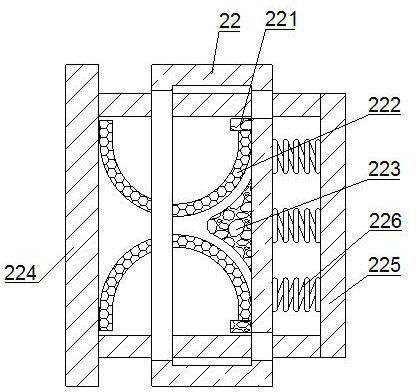

[0044] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the side buffer plates 22 of the rock slab are detachably installed on the inner surfaces of both sides of the composite rock slab shaping table 2, and the composite rock slab A lifter 23 is provided on the bottom outer surface of the shaping table 2, the output end of the lifter 23 extends to the top inner surface of the composite rock slab shaping table 2, and a push plate is detachably connected to the output end of the lifter 23 24. The outer surface of one side of the rock slab side buffer plate 22 extends to the outer surface of the composite rock slab shaping table 2, and the outer surfaces of both sides of the composite rock slab shaping table 2 are detachably connected with support legs 21, A fixing block 1 221 is detachably connected to the inner surface of the right side of the side buffer plate 22 of the rock slab, and the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com