Oil return method for shaft seat lubricated by circulating oil

A technology of circulating oil and lubricating oil, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient lubrication of parts and components, and achieve sufficient and reliable lubrication and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

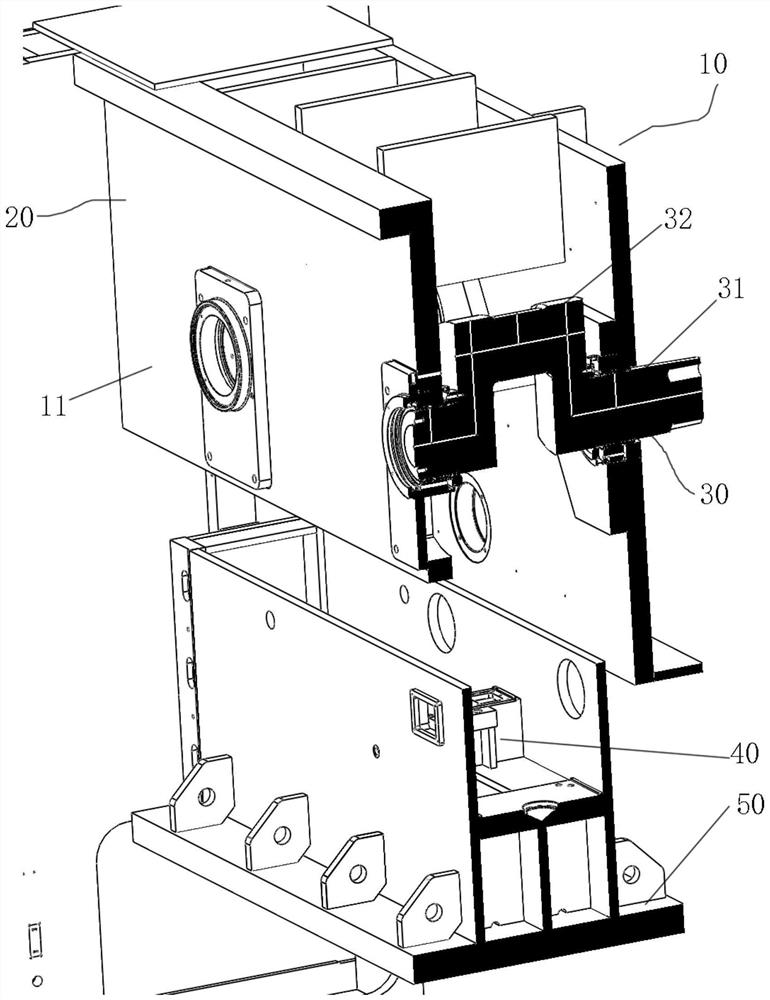

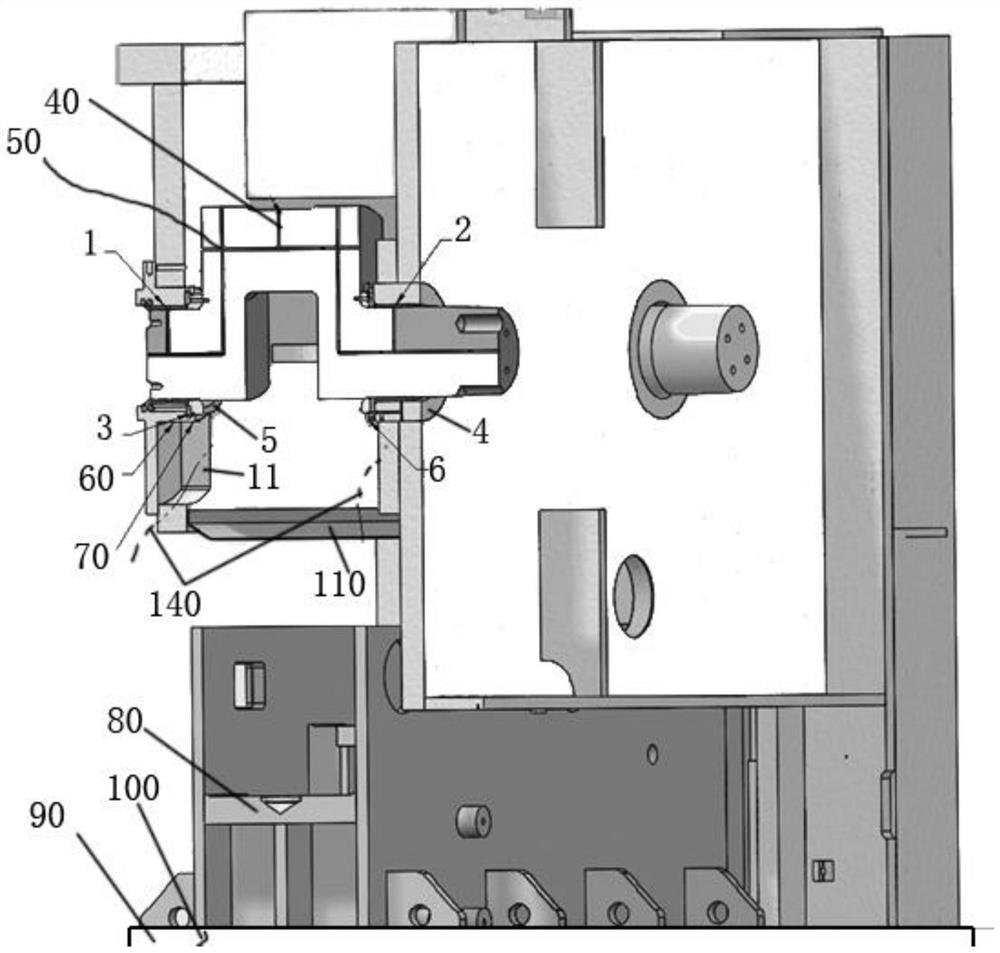

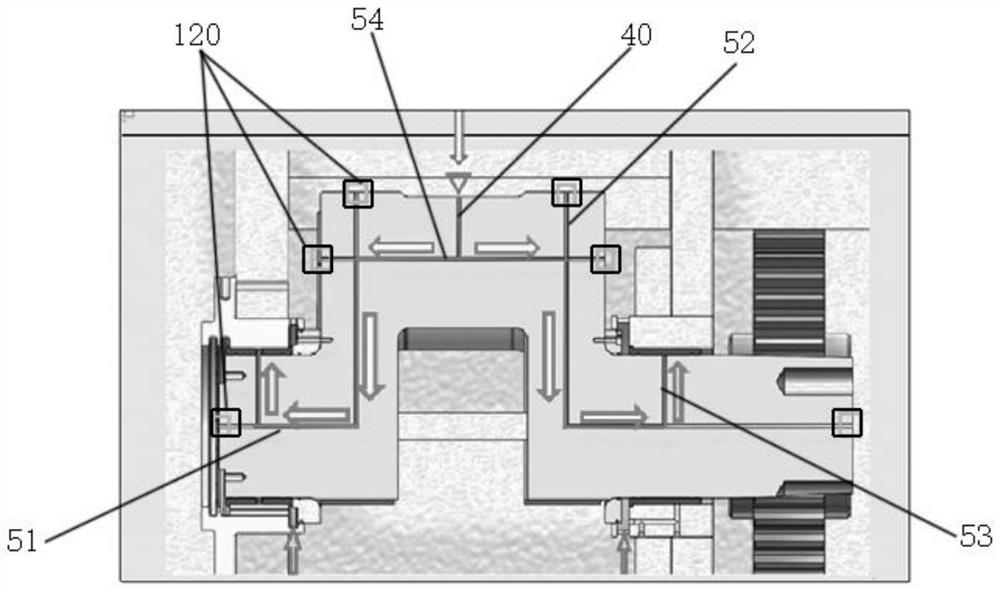

[0022] A method of returning oil to the shaft seat with circulating oil lubrication, see Figure 1-Figure 3 : it includes a frame 10, a crankcase 20, an oil tank (not shown in the figure), the frame 10 is provided with an oil tank corresponding to the lower position of the crankcase 20, and at least one crankshaft 30 is arranged in the crankcase 20, The two shaft ends of the crankshaft 30 are respectively mounted on the mounting and positioning holes of the corresponding frame side plates 11 through the corresponding copper bushings and bushing mounts, and the main body 31 of the crankshaft 30 is provided with an oil inlet hole groove 40 and a guide oil hole groove 50 , the oil tank injects high-pressure thin oil into the oil inlet groove 40 through the oil pump, and the thin oil flows along the oil inlet groove 40 and the guide oil hole groove 50 into the inner and outer ring surfaces of the copper bushing, so that the lubricating oil completes the copper bushing. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com