Adjustable alumite gold stamping equipment

An anodized aluminum, adjustable technology, applied in thin material processing, printing, printing machines, etc., can solve problems affecting the quality of hot stamping, separation of hot stamping paper and tipping paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

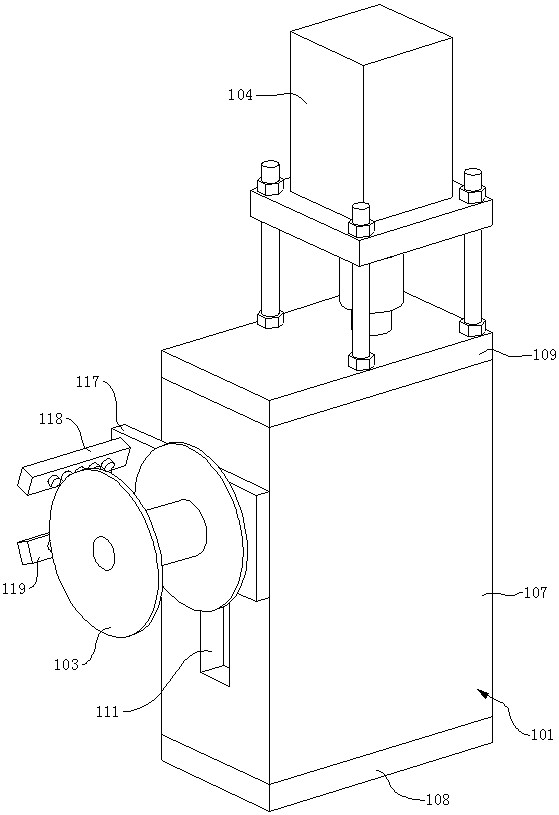

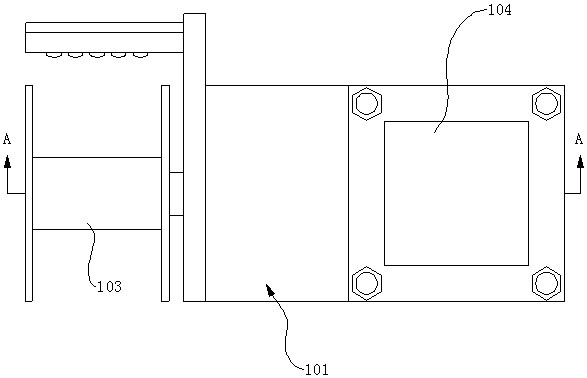

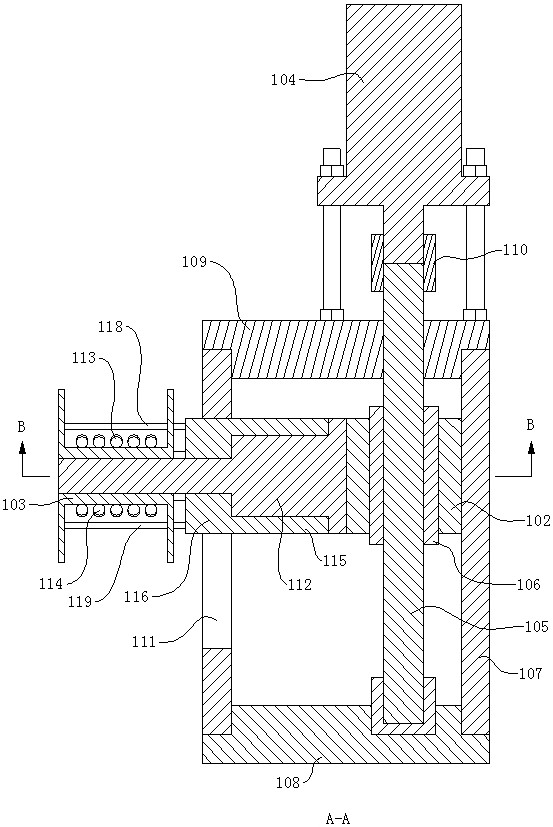

[0032] The embodiments of the present application will be described in further detail below with reference to the accompanying drawings and examples. The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

[0033]In the description of the embodiments of the present application, it should be noted that reference is made to the terms "the above-mentioned embodiments", "some embodiments", "the above-mentioned embodiments", "some embodiments", "possible embodiments" or "possible embodiments" The description of "an embodiment" or the like means that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one example or example of the embodiments of the present application. In this specification, schematic representations of the above terms are not necessarily directed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com