Manufacturing method of ceramic ornament inlaid with metal structure

A manufacturing method and metal structure technology, applied in decorative structures, ceramic molding machines, manufacturing tools, etc., can solve the problems of poor use feeling of ceramic ornaments, and achieve the effects of high aesthetics, enhanced structure, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

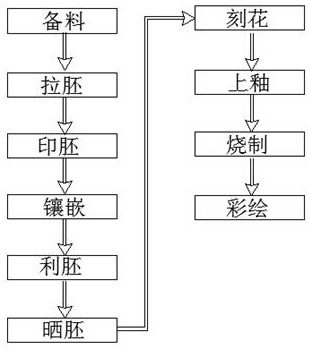

[0036] refer to figure 1 , a method for making a ceramic ornament inlaid with a metal structure, comprising the following steps:

[0037] S1: Prepare materials, take porcelain stone from the mining area, crush it manually with a hammer to the size of an egg, and then use a water masher to beat it into powder, wash it out, remove impurities, and make a brick-shaped mud block after precipitation. Then mix the mud with water;

[0038] S2: Pull the blank, throw the mud ball on the center of the turntable of the reel car, and pull out the shape of the blank with the flexion and extension of the technique, and complete the first process of forming;

[0039] S3: printing blank, the shape of the stamping die is formed by rotating according to the inner shape of the blank, cover the semi-dry blank on the mold, press the outer wall of the blank evenly, and then demould;

[0040] S4: Inlay, after demolding is completed, insert the metal to be inlaid into the embryo. The metal structure...

Embodiment 2

[0050] refer to figure 1 , a method for making a ceramic ornament inlaid with a metal structure, comprising the following steps:

[0051] S1: Prepare materials, take porcelain stone from the mining area, crush it manually with a hammer to the size of an egg, and then use a water masher to beat it into powder, wash it out, remove impurities, and make a brick-shaped mud block after precipitation. Then mix the mud with water;

[0052] S2: Pull the blank, throw the mud ball on the center of the turntable of the reel car, and pull out the shape of the blank with the flexion and extension of the technique, and complete the first process of forming;

[0053] S3: printing blank, the shape of the stamping die is formed by rotating according to the inner shape of the blank, cover the semi-dry blank on the mold, press the outer wall of the blank evenly, and then demould;

[0054] S4: Inlay, after demolding is completed, insert the metal to be inlaid into the embryo. The metal structure...

Embodiment 3

[0064] refer to figure 1 , a method for making a ceramic ornament inlaid with a metal structure, comprising the following steps:

[0065] S1: Prepare materials, take porcelain stone from the mining area, crush it manually with a hammer to the size of an egg, and then use a water masher to beat it into powder, wash it out, remove impurities, and make a brick-shaped mud block after precipitation. Then mix the mud with water;

[0066] S2: Pull the blank, throw the mud ball on the center of the turntable of the reel car, and pull out the shape of the blank with the flexion and extension of the technique, and complete the first process of forming;

[0067] S3: printing blank, the shape of the stamping die is formed by rotating according to the inner shape of the blank, cover the semi-dry blank on the mold, press the outer wall of the blank evenly, and then demould;

[0068] S4: Inlay, after demolding is completed, insert the metal to be inlaid into the embryo. The metal structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com