Seat leg support extension driving mechanism

A technology of drive mechanism and extension mechanism, applied in vehicle seats, special positions of vehicles, vehicle components, etc., can solve problems such as affecting extension speed and poor stability, and achieve the effects of optimized structure, smooth operation throughout the entire stroke, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the present invention is further described below.

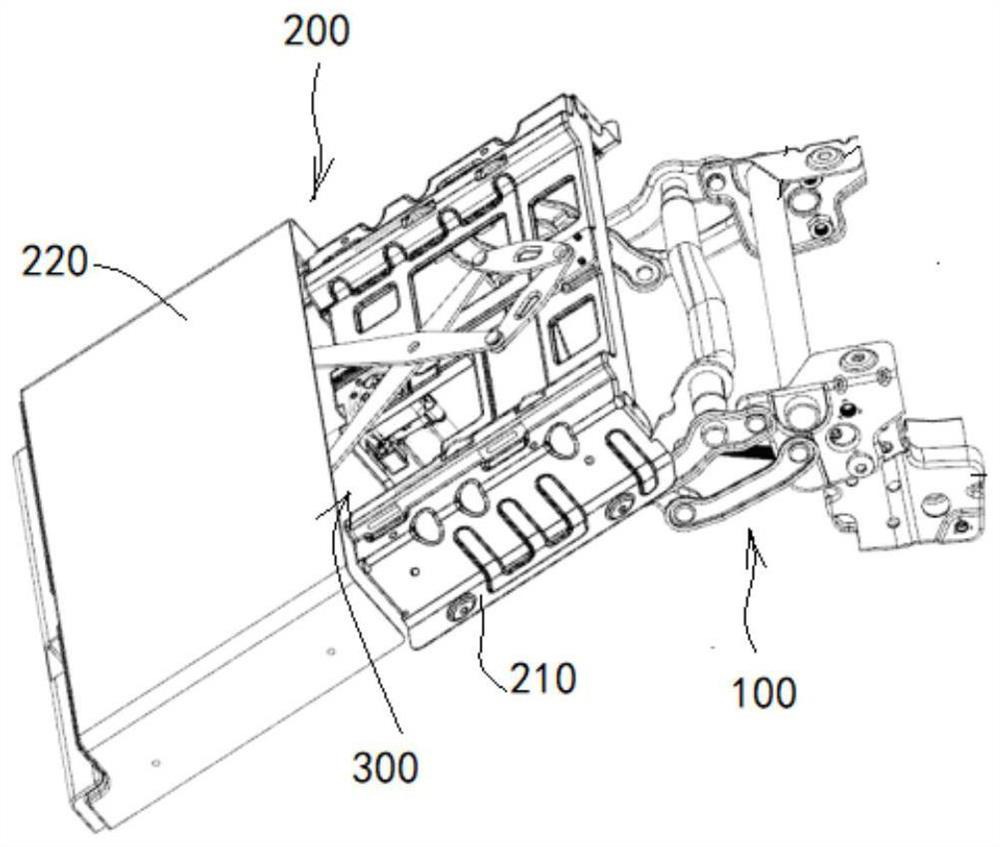

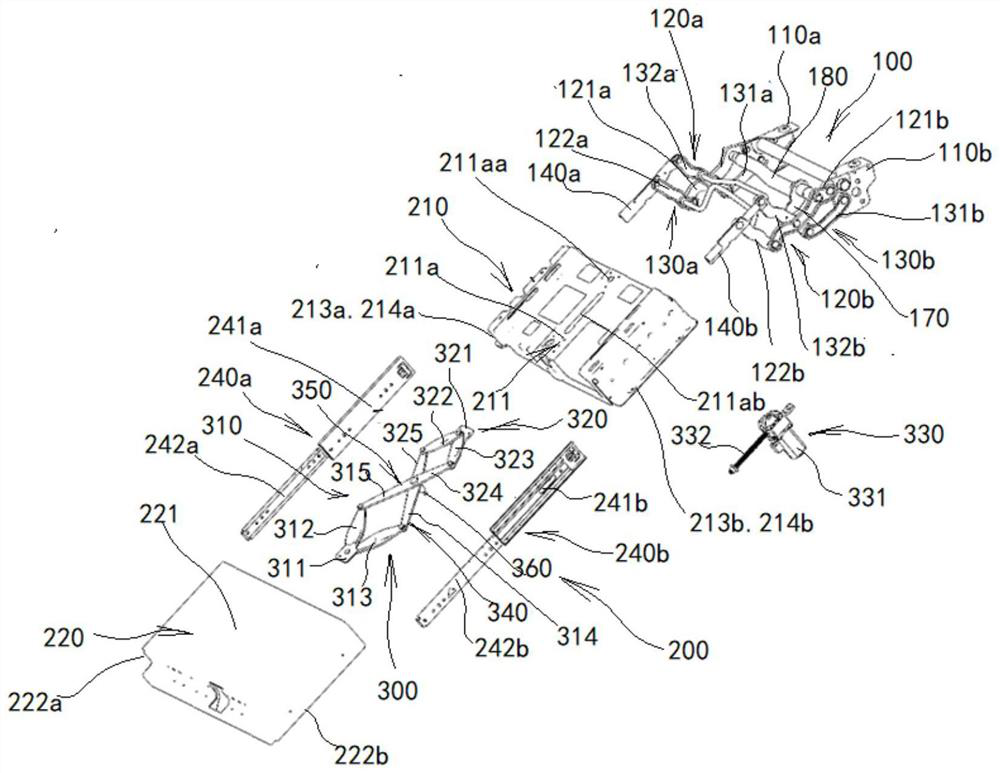

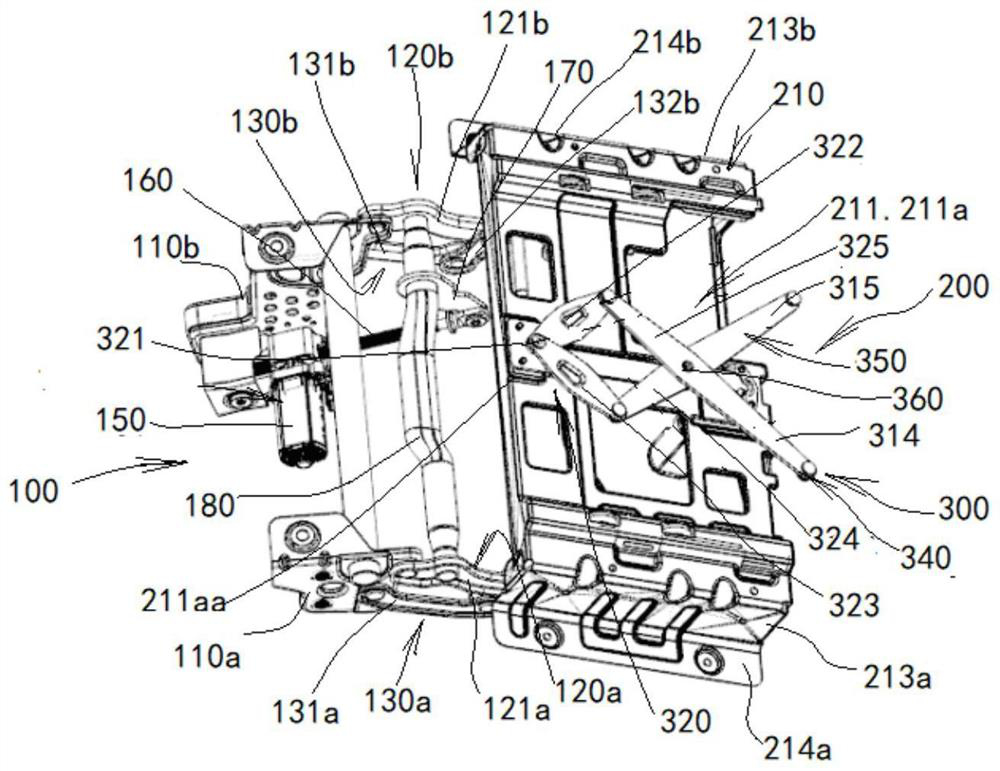

[0060] see Figure 1 to Figure 20 The shown seat leg rest extension driving mechanism includes a leg rest mechanism 200 , a turning mechanism 100 , and an extension mechanism 300 . The turning mechanism 100 connects the leg rest mechanism 200 to the seat frame (not shown in the figure), and the extension mechanism 300 is slidably arranged on the leg rest mechanism 200 and drives the leg rest mechanism 200 to reciprocate.

[0061] The turning mechanism 100 includes a connecting member connected to a seat frame (not shown in the figure), a turning member and a turning driving mechanism.

[0062] The connecting member includes a pair of connecting frames 110a, 110b fixed on the left and right sides of the seat frame (not shown).

[0063] The inversion member includes a pair of connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com