Intelligent warehousing system

A warehousing system and rotating plate technology, applied in the field of warehousing and transportation, can solve the problems of low efficiency of goods handling, slow manual inventory of goods, waste of resources, etc., and achieve the effect of convenient and rapid confirmation and execution, convenient access and labor-saving, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" as used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

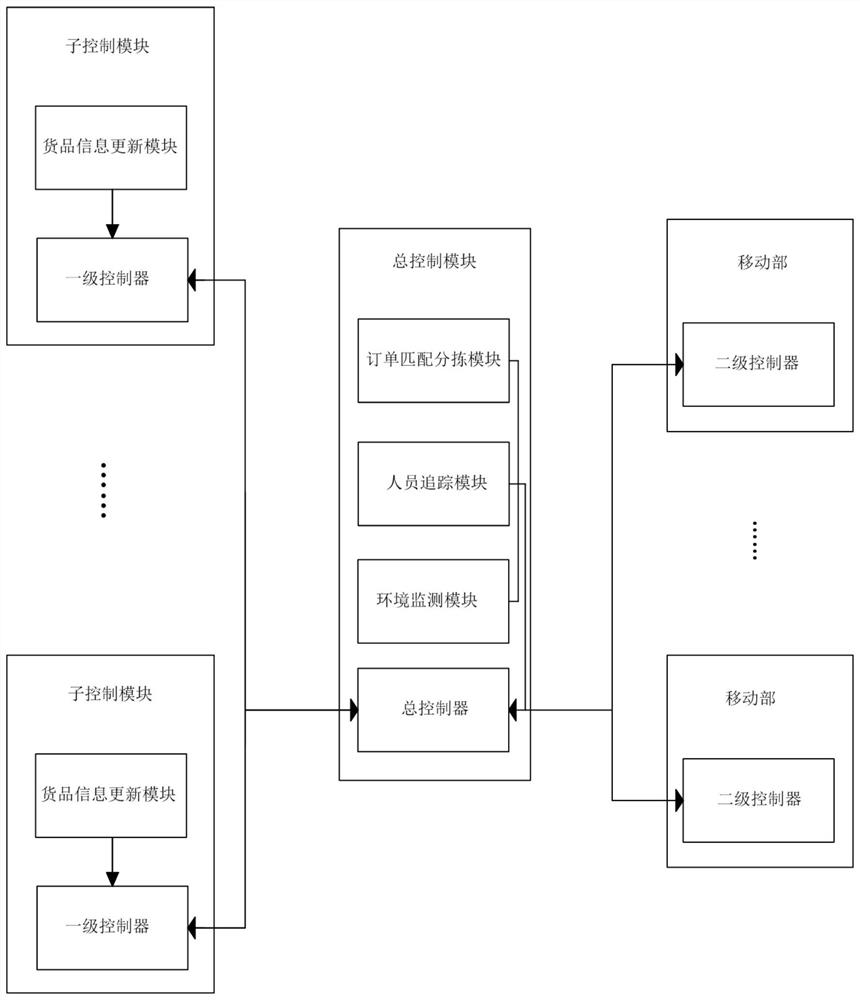

[0035] like figure 1 and 2 As shown, the present invention provides an intelligent storage system, including:

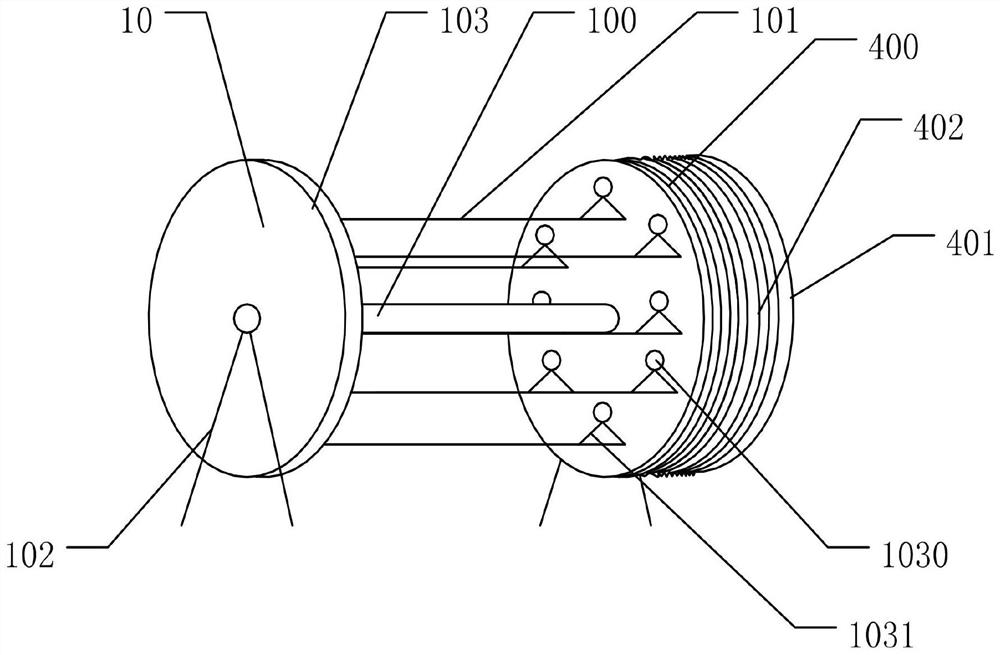

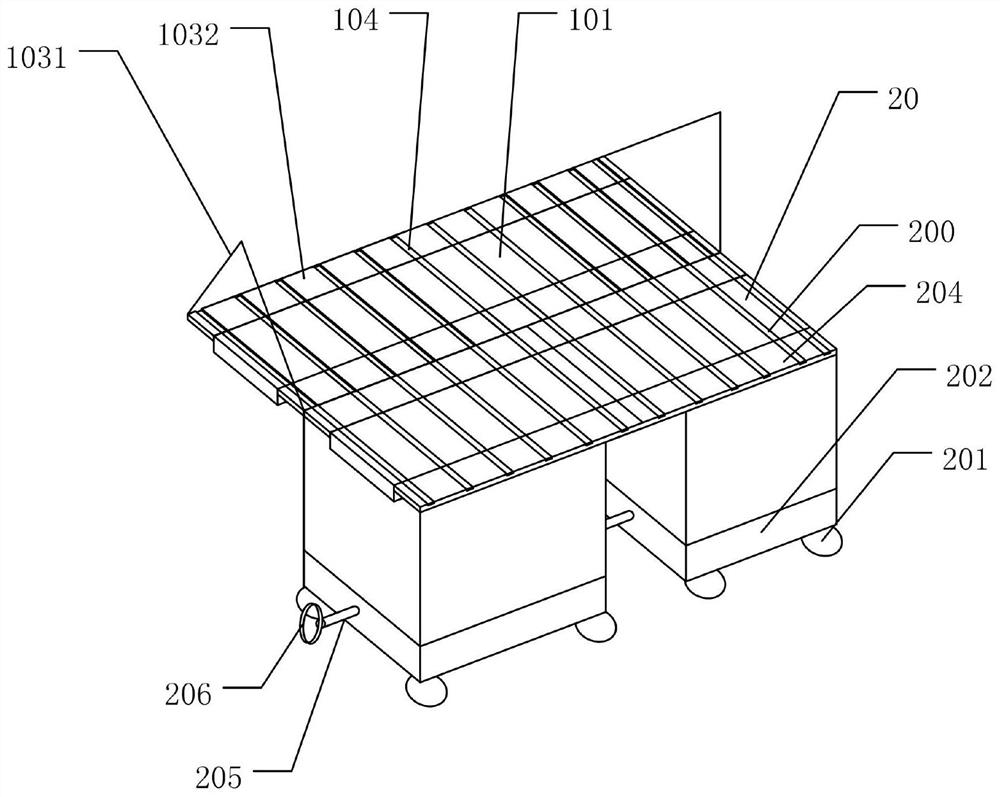

[0036]The shelf main body 10 includes a support portion symmetrically arranged in the front and rear; a rotating shaft 100 and a plurality of storage boards 101; the support portion includes a bracket 102, and both ends of the rotating shaft 100 are respectively rotatably arranged on the top of the bracket 102 ; a rotating plate 103, which is provided with a connecting shaft connected with the rotating shaft 100, so that the rotating plate 103 rotates synchronously wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com