Efficient construction film covering equipment for highway engineering

An engineering and high-efficiency technology, applied in mechanical equipment, roads, buildings, etc., can solve problems that affect the aesthetics and smoothness, lose the effect of roadbed maintenance, and the film is easy to be blown by strong winds, etc., to achieve the maintenance effect and limit protection Fixed effect, guarantee effect of coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

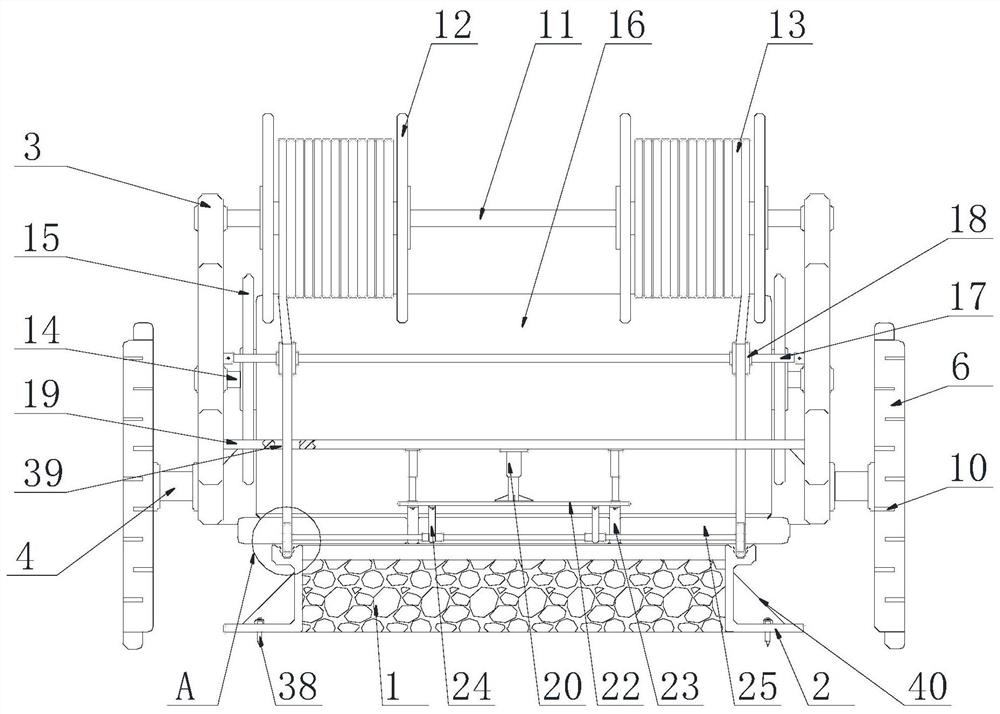

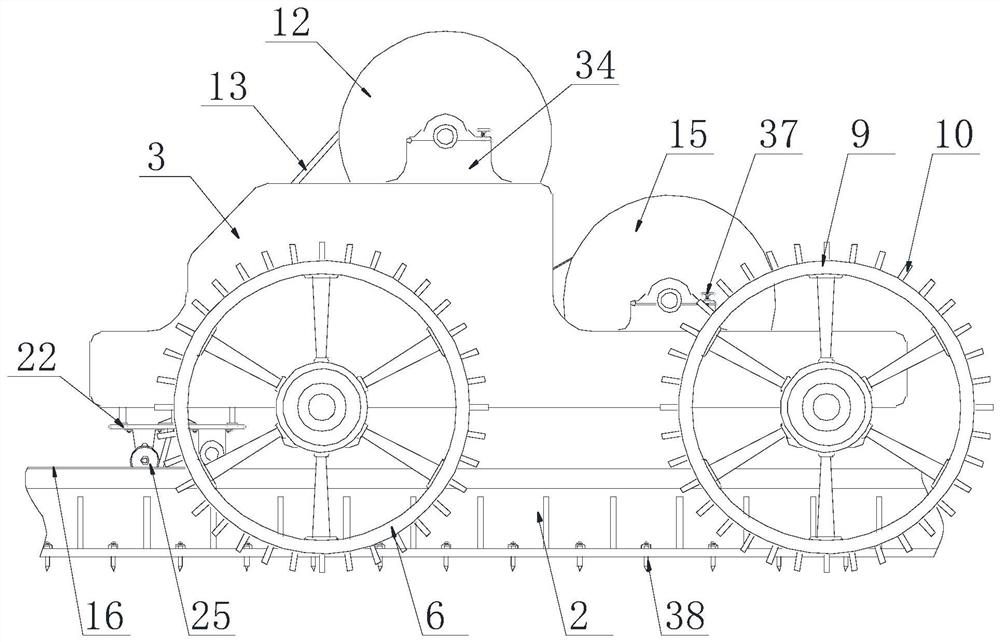

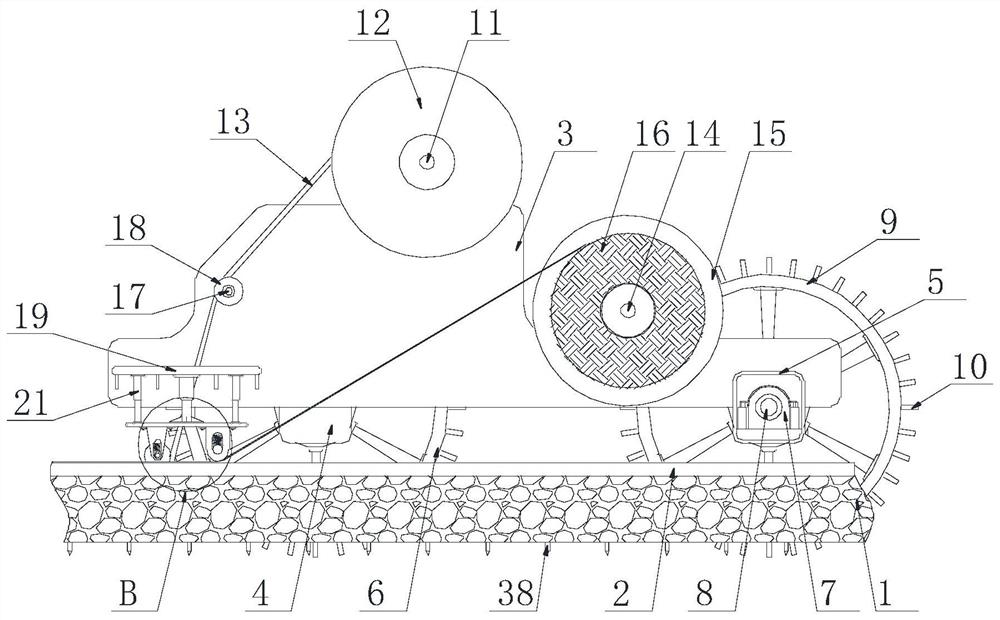

[0036] Please see attached figure 1 to the attached image 3 , a high-efficiency laminating equipment for highway engineering construction, including baffle plate 2, mounting plate 3, driving moving assembly, first drum assembly, second drum assembly, seal 13, film 16, drum assembly, drum 25, roller 32 and the roller assembly; the baffle 2 has an L-shaped structure, the vertical sections of a pair of baffles 2 are respectively attached to the end surfaces on both sides of the roadbed 1, and the horizontal sections of a pair of baffles 2 are respectively fixed on the side of the roadbed 1. On the ground; the driving moving assembly is erected on the outside of a pair of baffles 2 (that is, the side away from the roadbed 1) and above the roadbed 1, and a pair of mounting plates 3 are respectively arranged on the driving moving assembly and located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com