Membrane bag concrete and corrugated steel plate combined tunnel preliminary bracing structure

A corrugated steel plate and initial support technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of affecting the support strength and sealing performance of the pouring area, the concrete is easy to overflow, and the waste of concrete materials, etc., to achieve reduction The effect of spillage, material saving and repair cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

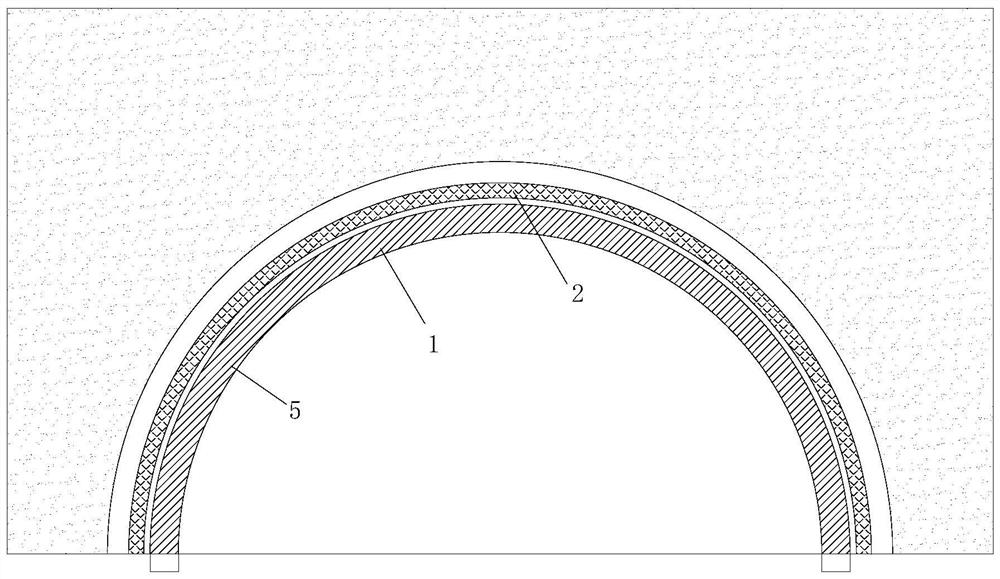

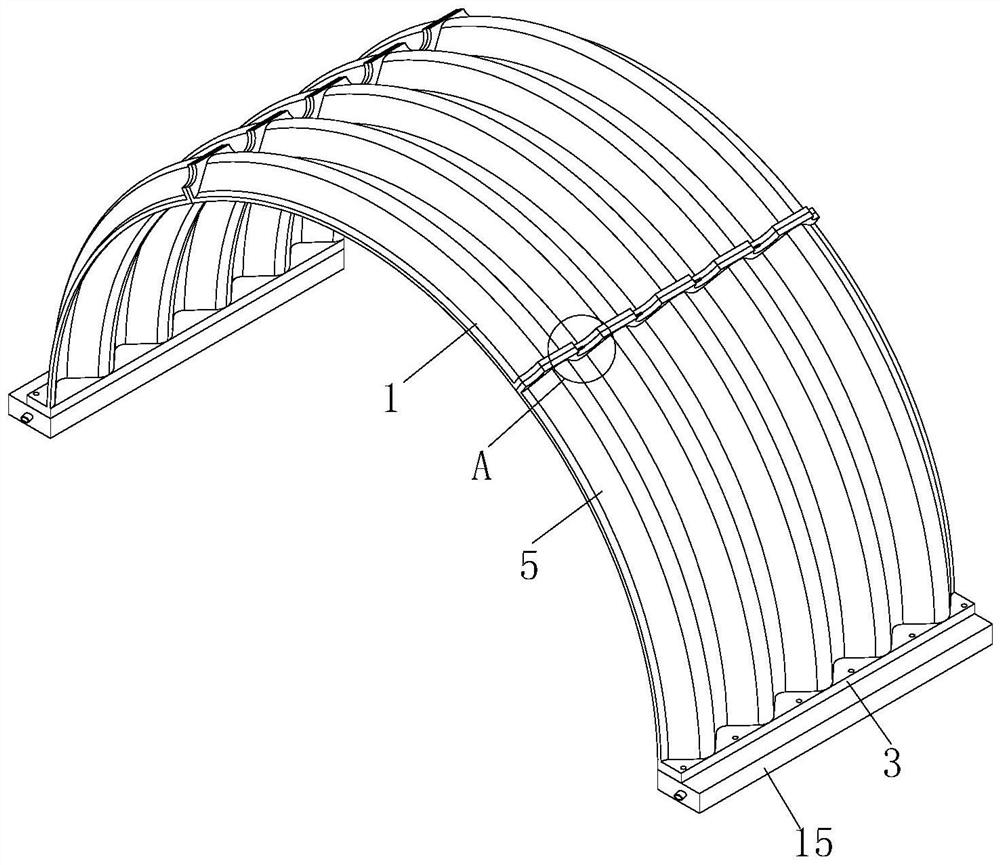

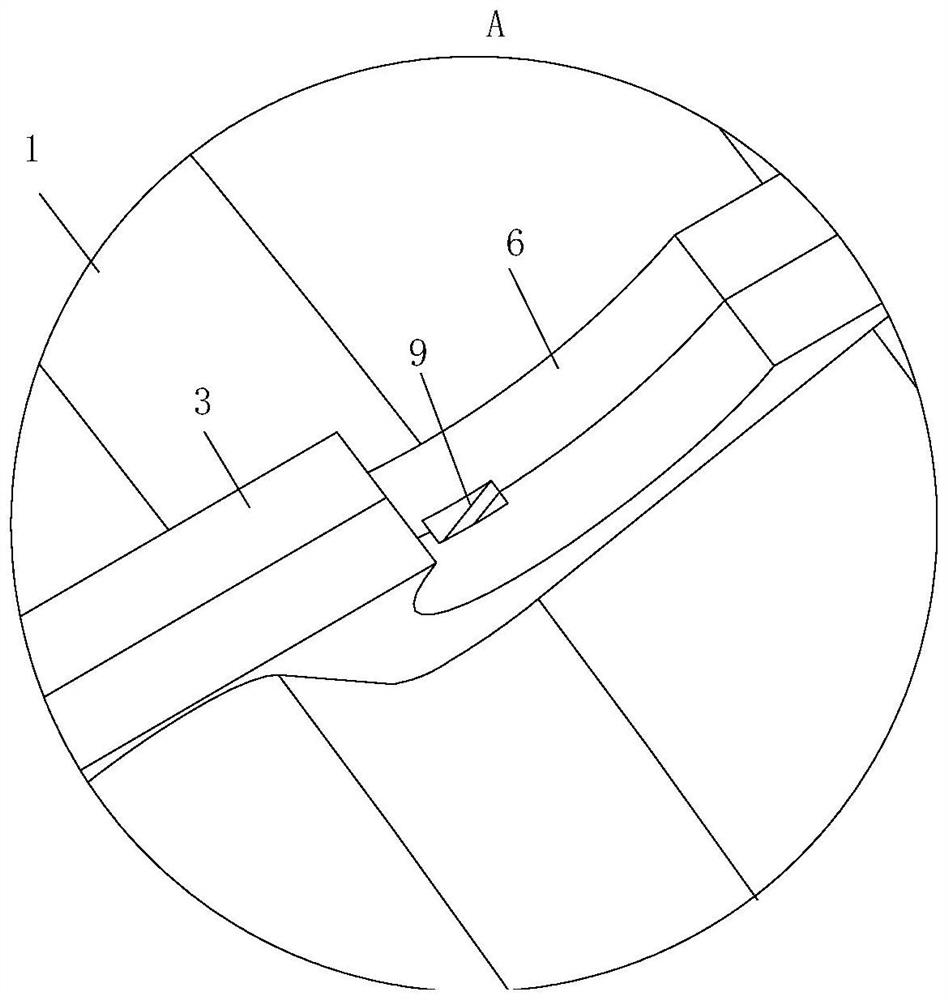

[0034] refer to Figure 1-2 , an initial support structure of a tunnel in which film bag concrete and corrugated steel plates are combined, comprising a corrugated steel plate body 1 and a film bag body 2; the two ends of the corrugated steel plate body 1 are welded with connecting plates 3, and a plurality of connecting plates 3 are opened on the connecting plate 3 The fixing hole 4, two adjacent corrugated steel plate bodies 1, are fixed together by the connecting plate 3, and spliced into an arch-shaped support plate 5, the outer arc surface of the support plate 5 is covered with a film bag body 2, and the film bag body 2. It is laid along the inner concave surface of the outer surface of the corrugated steel plate body 1, and the membrane bag body 2 is filled with concrete; the membrane bag concrete is made of double-layer high-strength woven chemical fiber fabric into a continuous (or separate) bag body as a flexible formwork The protective structure is formed by fillin...

Embodiment 2

[0044] refer to Figure 10 , Comparative Example 1, as another embodiment of the present invention, wherein a plurality of communication bag bodies 22 are arranged between the main bag bodies 7 in the same row, and the communication bag bodies communicate with two adjacent main bag bodies 7 in the same row; A plurality of communicating bag bodies 22 are provided to connect the main bag bodies 7 with each other, so that when pouring concrete, the concrete can quickly and evenly spread to each position in the film bag, so that the support formed by the film bag body 2 and the support plate 5 The structure is stable and uniform against the pressure of the soil.

[0045] Working principle: first build the support plate 5, then lay the membrane bag body 2 on the surface of the protrusion 16 of the support plate 5, and then pump the concrete into the membrane bag body 2 through the concrete pump, and the membrane bag body 2 gradually bulges. air, so that the pouring area between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com