Annular yielding supporting structure for yielding supporting of tunnel and yielding method

A support structure and hoop technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems that the final deformation of the surrounding rock cannot be immediately limited, and achieve the effect of simple manufacture and convenient assembly of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

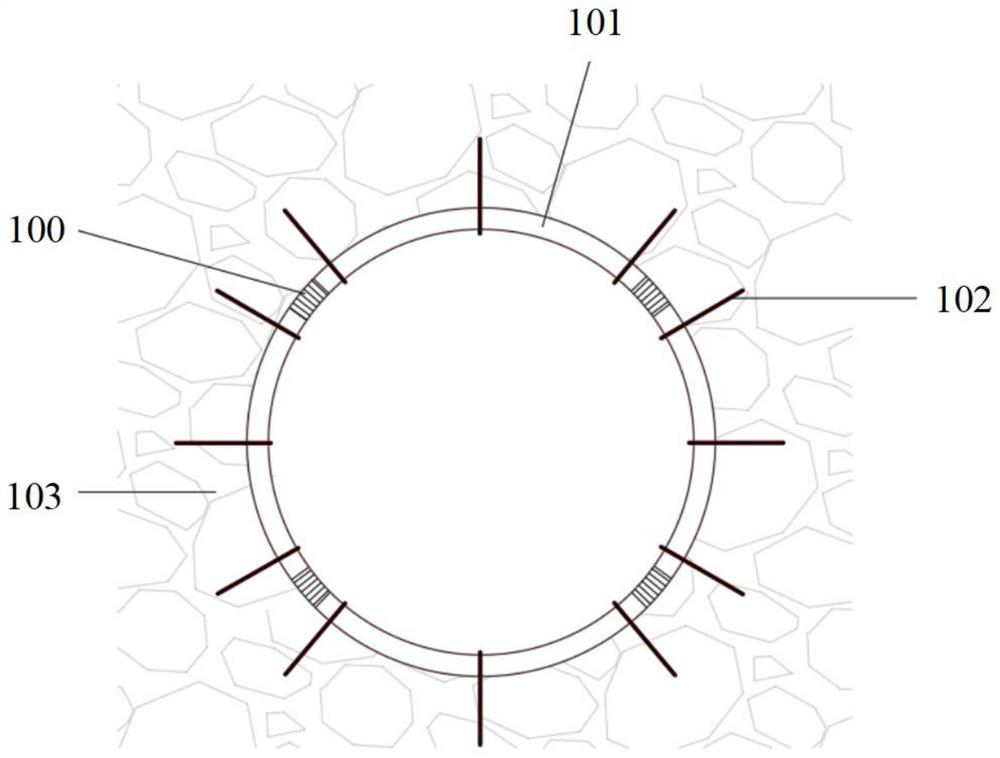

[0031] see figure 1 , the present invention provides a circumferential pressure yielding support structure for tunnel yielding support, comprising a plurality of adjacent arch units 101 connected end to end through the circumferential yielding pressure node device 100 to form a circumferential pressure yielding structure, The hoop yielding structure is fixed in the tunnel by means of fixing anchors 102 .

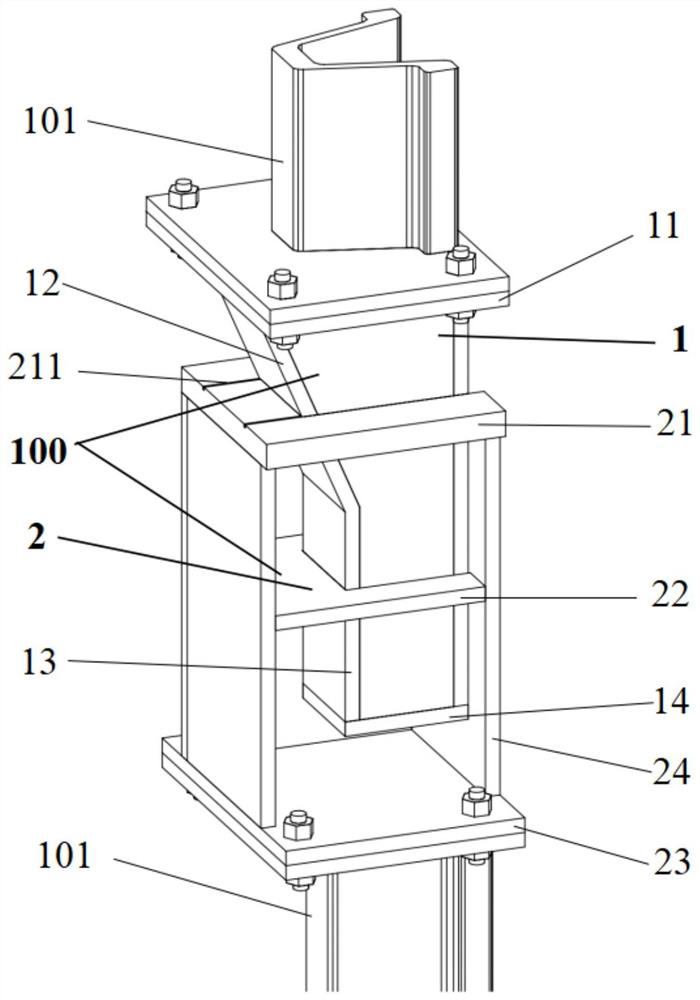

[0032] see figure 2 , the annular pressure drop point device 100 includes a wedge-shaped plug 1 and a socket 2; the wedge-shaped plug 1 is inserted into the socket 2, and the outer ends of the two are connected to the arch unit 101 respectively.

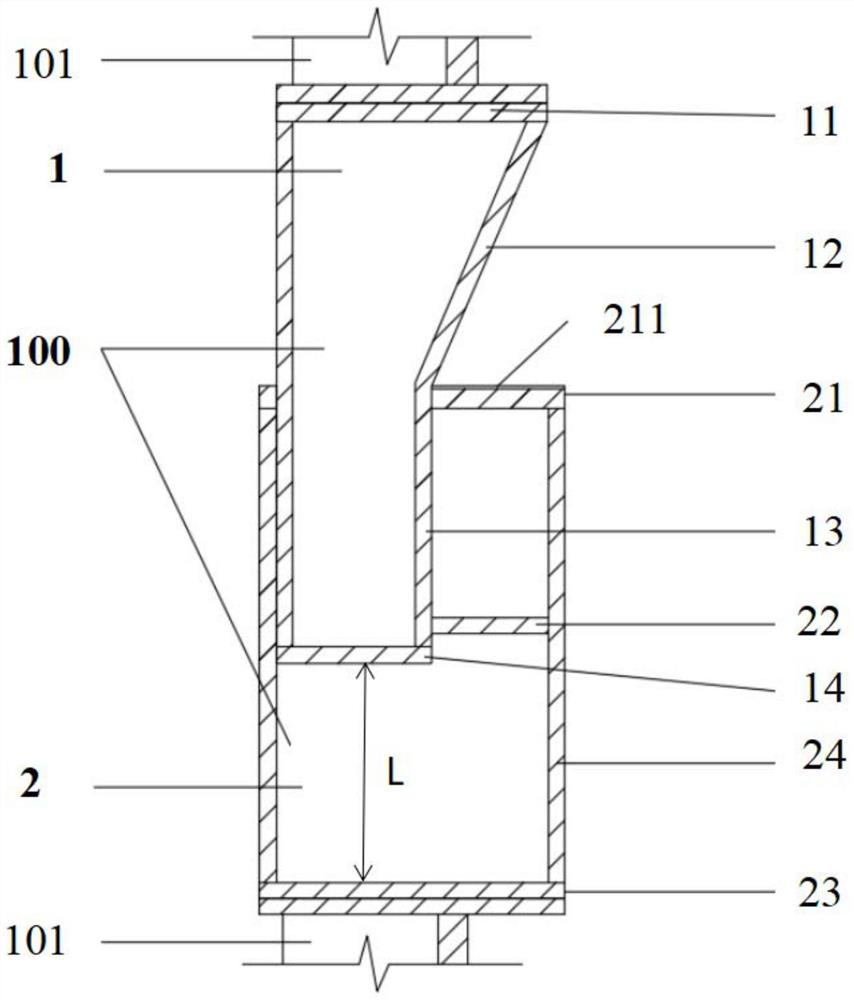

[0033] see image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com