An installation process of prefabricated composite support structure based on section steel

A prefabricated assembly and installation process technology, applied in the installation of bolts, shaft equipment, shaft lining and other directions, can solve the problems of small shrinkage, waste of funds, structural instability, etc., to improve stress conditions, reduce mold costs, Avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

[0043] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

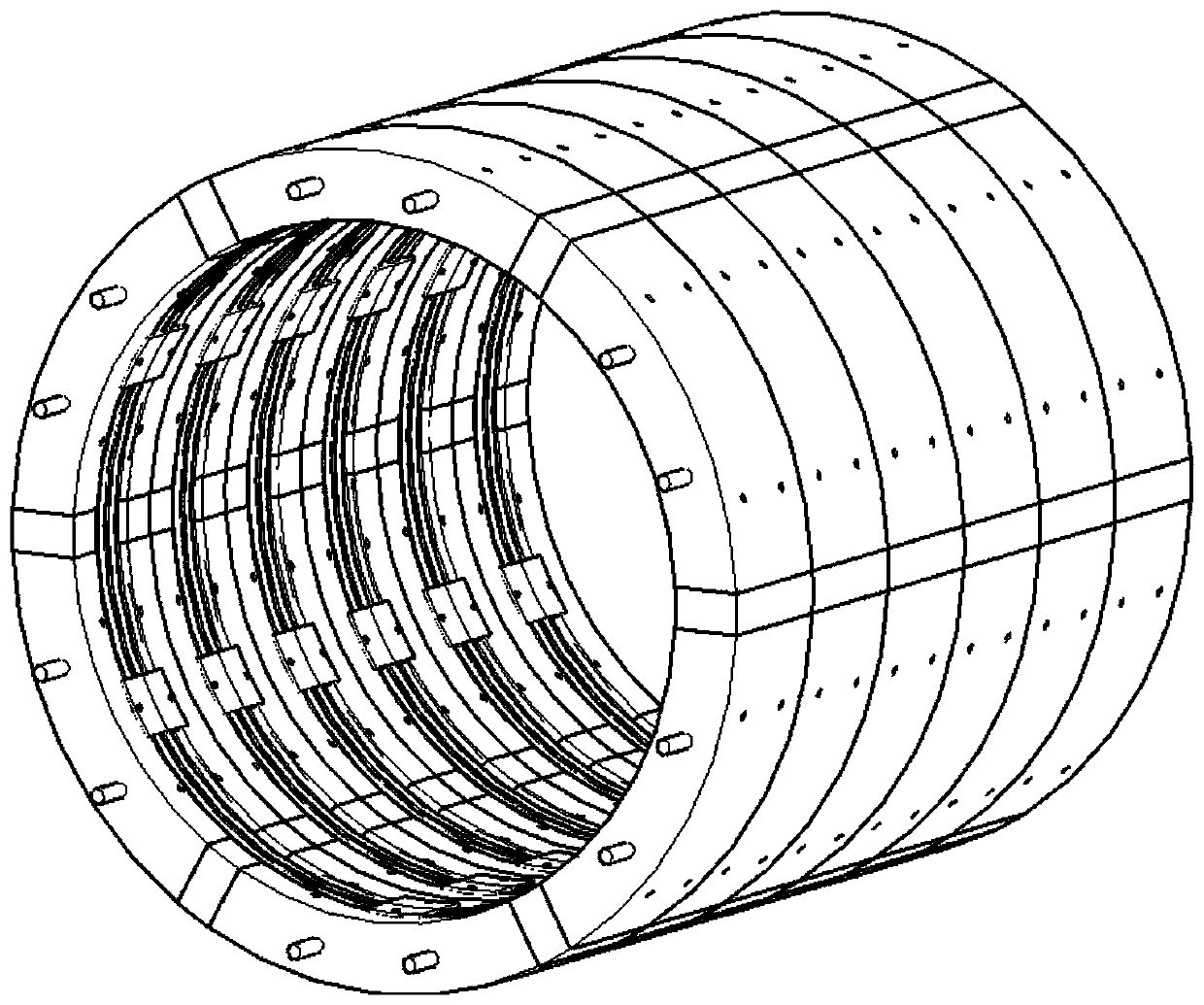

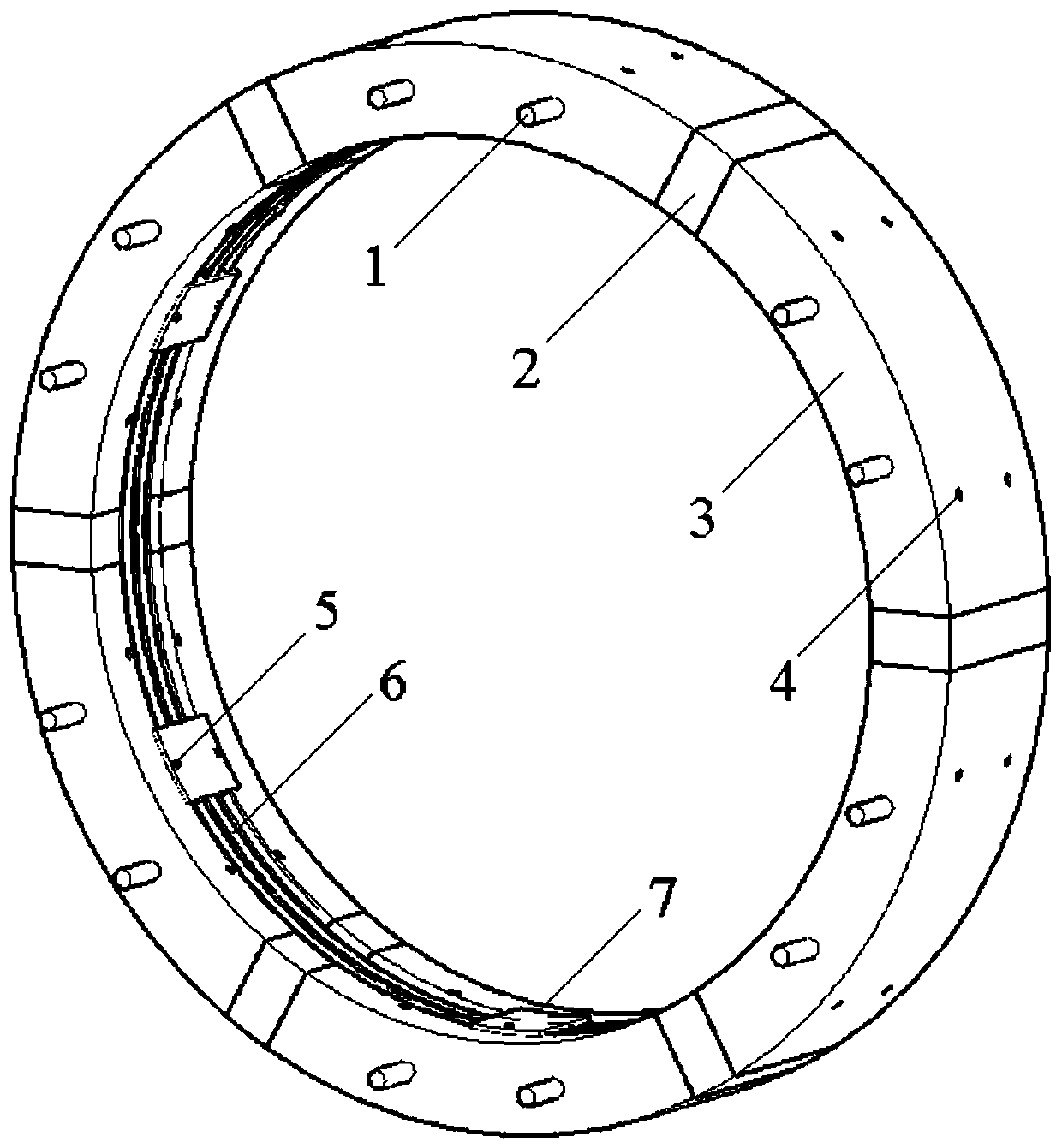

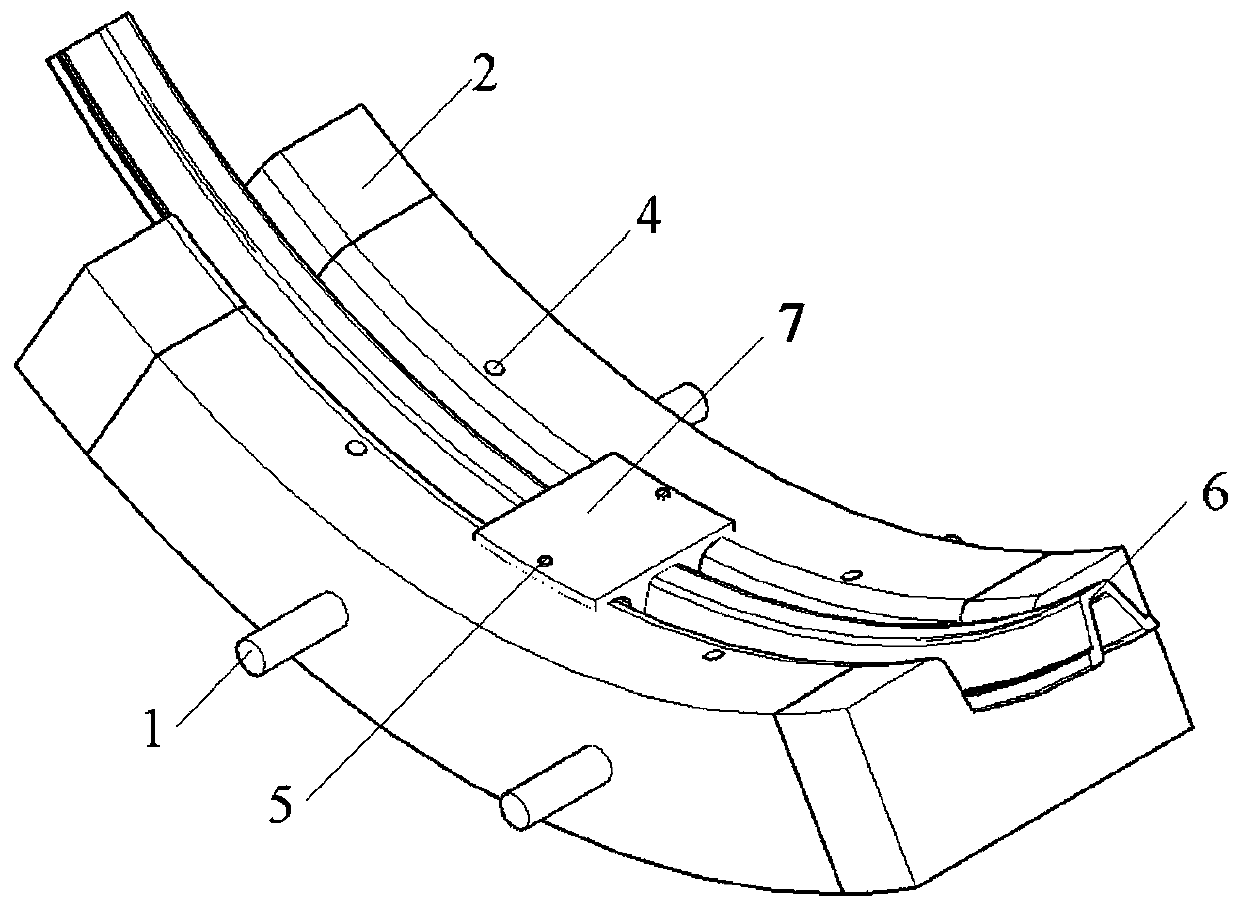

[0044]As shown in the figure, the present invention includes a single-ring support structure, in which steel is embedded in the single-ring support structure, and the structural shape of the single-ring support structure matches the channel profile; a plurality of the single-ring support structures The supporting structures are axially connected along the channel to form the supporting system. Specifically, the single-ring support structure includes a multi-section prefabricated assembly structure 3; multiple sections of the prefabricated assembly structure 3 are assembled together to form the single-ring support structure; a plurality of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com