Variable geometry combustion chamber diffuser structure and application

A diffuser and combustion chamber technology, applied in the field of combustion chamber diffuser structure, can solve the problems of unbalanced air flow, large pressure loss, large vortex, etc., and achieve high uniformity of outlet temperature distribution, high temperature peak value, and high performance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

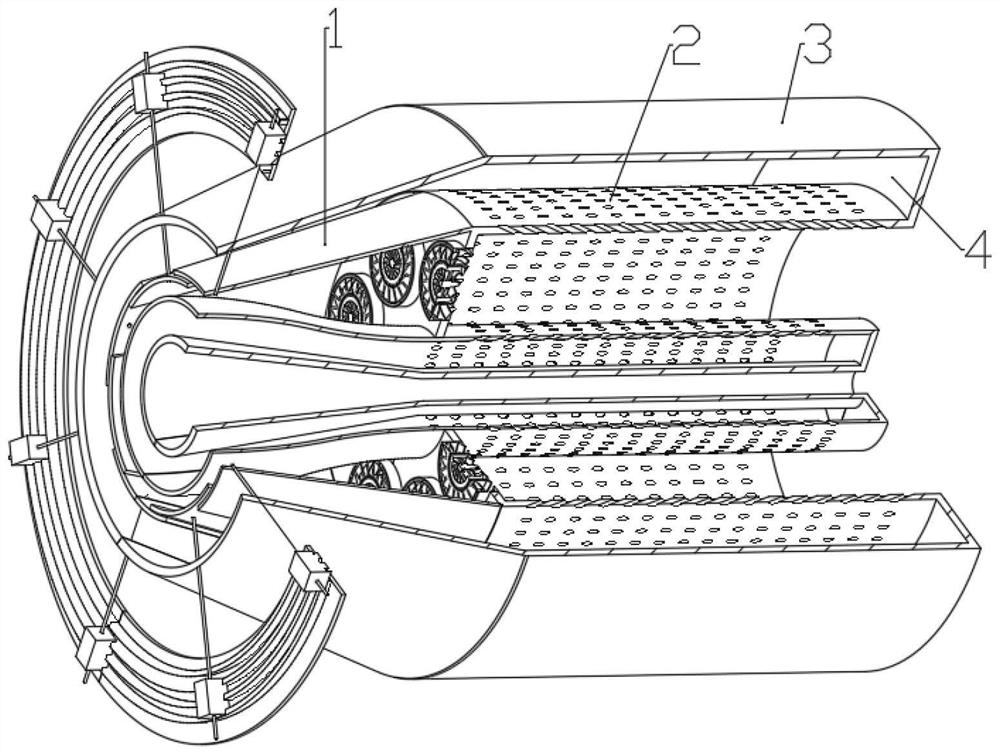

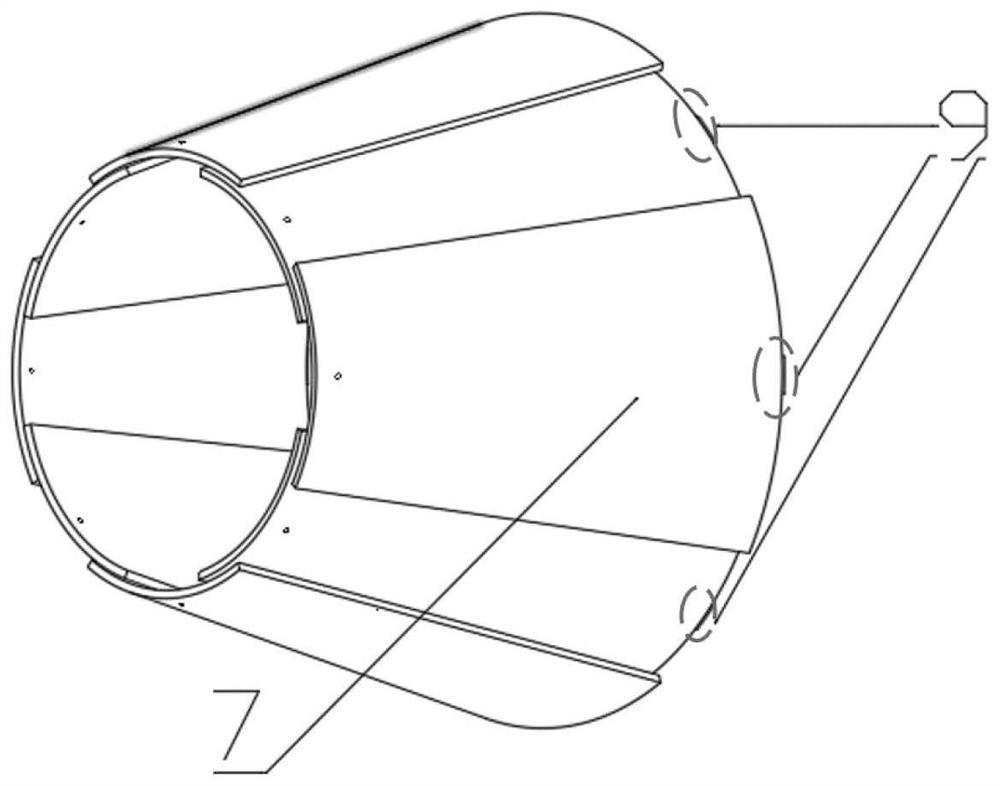

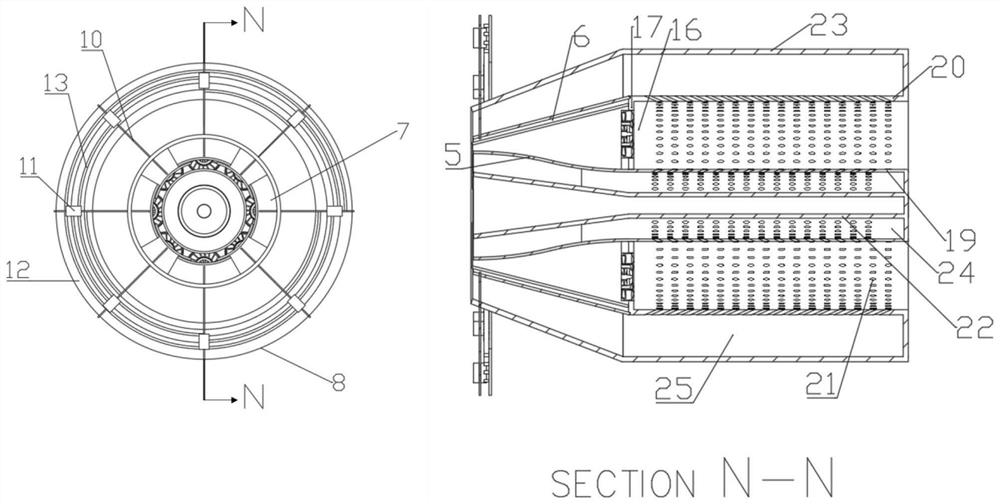

[0036] like figure 1 As shown, the outer diffuser 6 includes eight diffuser plates 7, and the angle occupied by each diffuser plate 7 is 60°, and the initial angle between two adjacent diffuser plates 7 is 45°. The angle will change, that is, the overlapping part between the two adjacent diffuser plates 7 will change. When the airflow demand at the head of the flame cylinder increases, the overlapping part between the diffuser plates 7 will decrease. When decreasing, the overlapping portion between the diffuser plates 7 increases, and the radial distance between two adjacent diffuser plates 7 is 1 mm, which ensures that the movement of each diffuser plate 7 does not interfere with each other and affects the air leakage at the same time. .

[0037] like figure 1 and image 3 As shown, the diffuser inlet control portion 8 includes a push-pull rod 10 , a moving block 11 , a gear 12 and a gear upper rail 13 . A stepper motor is used to drive the gear 12 to rotate, and the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com