Ultra-low permeability tight reservoir fracture-pore type core preparation and saturated oil experiment method

A tight reservoir, ultra-low permeability technology, used in the preparation of test samples, permeability/surface area analysis, suspension and porous material analysis, etc. Influence, does not consider whether the saturation method is applicable, etc., to prevent falling off and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

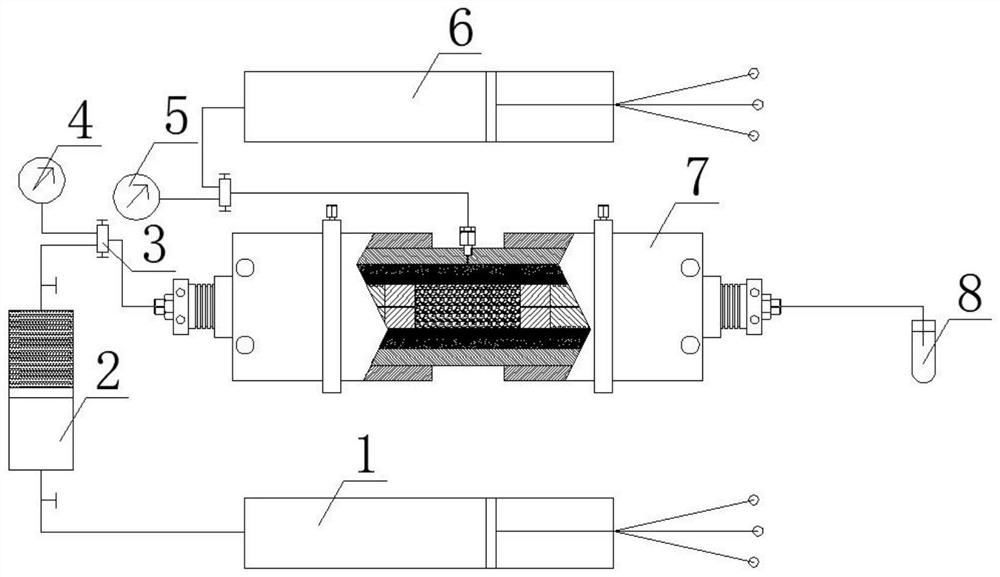

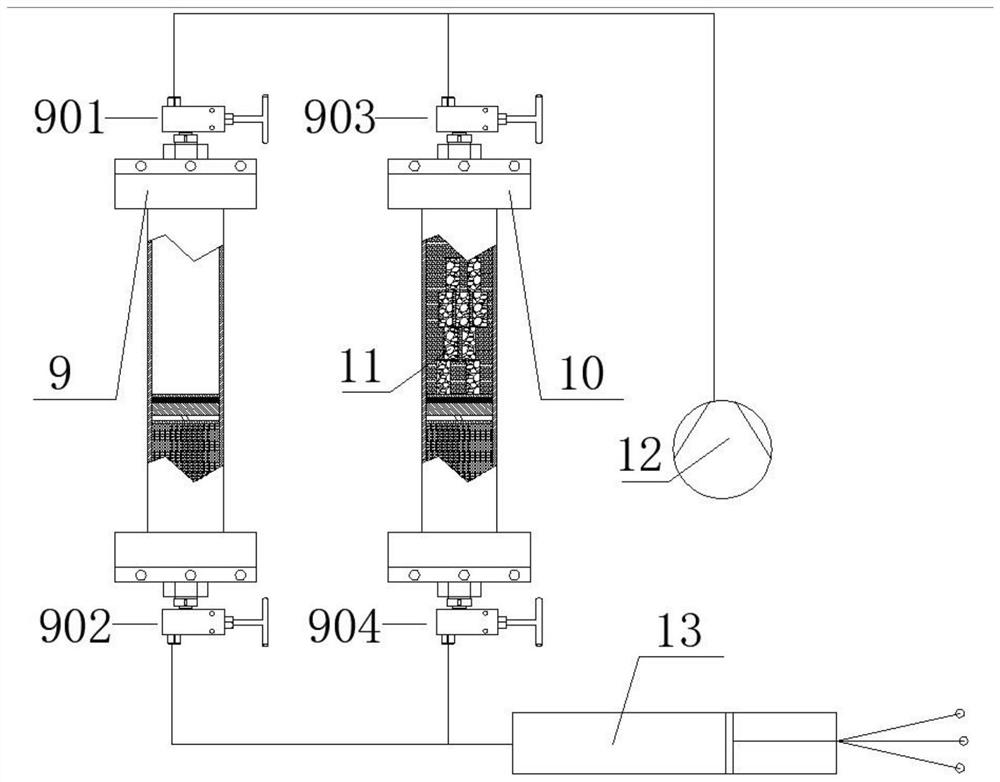

[0046] The present invention is further described below according to the accompanying drawings and examples, so as to facilitate the understanding of the present invention by those skilled in the art. However, it should be clear that the present invention is not limited to the scope of the specific embodiments. For those skilled in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all protected. List.

[0047]An ultra-low permeability tight reservoir fracture-porous core preparation and oil-saturated experimental method, comprising the following steps in sequence;

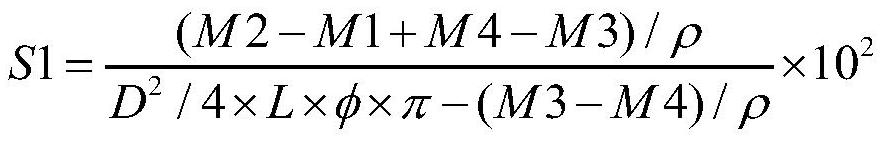

[0048] (1) Carry out edge removal treatment on the core to obtain a cylindrical core with a length of L=4.757cm and a diameter of D=2.564cm;

[0049] (2) Place the core in an intermediate container containing petroleum ether, pressurize it to 10MPa higher than the formation pressure, and after standing for 12 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com